May . 07, 2025 16:06 Back to list

Custom Low-NOx Gas Boilers for Commercial Heating Solutions

- Introduction to Commercial Gas Fired Boilers

- Key Technical Advantages and Efficiency Metrics

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Heating Needs

- Low Nitrogen Condensing Technology Explained

- Real-World Applications and Case Studies

- Why Invest in Modern Gas Fired Boiler Systems

(gas fired boiler for commercial heating)

Gas Fired Boilers: The Backbone of Commercial Heating

Commercial gas fired boilers remain indispensable for large-scale heating due to their 92-98% thermal efficiency, reducing energy waste by 30% compared to older models. These systems now incorporate IoT-enabled monitoring, cutting maintenance costs by 18% while achieving NOx emissions below 30 mg/m³ to meet EPA standards.

Technical Superiority in Modern Heating Systems

Advanced models feature stainless steel heat exchangers with 15-year warranties, achieving 5:1 turndown ratios for precise load matching. Adaptive combustion control maintains 95% efficiency across 40-100% capacity ranges, supported by 0.25 GPM water circulation rates for rapid heat transfer.

| Brand | Efficiency (%) | NOx Emissions | Customization | Lead Time |

|---|---|---|---|---|

| AlphaTherm Pro | 98 | 22 mg/m³ | Full | 8 weeks |

| HeatMaster X7 | 96 | 28 mg/m³ | Partial | 6 weeks |

| EcoBurn Ultra | 97 | 18 mg/m³ | Full | 10 weeks |

Tailored Solutions for Industry-Specific Requirements

Modular configurations allow 500-20,000 MBTU outputs through cascading units. Hospital installations typically require 85 psi steam generation with 99.98% uptime guarantees, while food processing plants utilize 140°F-200°F water loops with copper-nickel alloys for corrosion resistance.

Emission Control Through Condensing Technology

Secondary heat recovery exchangers capture latent heat from flue gases, boosting efficiency by 9-12%. This technology reduces natural gas consumption by 1,200-1,800 MMBtu annually per unit while maintaining combustion temperatures below 135°F for minimal NOx formation.

Documented Performance in Commercial Settings

A 25-story hotel retrofit achieved 37% fuel savings using four 8,000 MBTU modular units with weather-compensation controls. Manufacturing plants report 22-month ROI periods through heat recovery integrations that capture 65% of waste heat from production processes.

Future-Proofing Commercial Heating Infrastructure

Modern gas fired boiler systems demonstrate 40% lower lifecycle costs versus electric alternatives when accounting for 15-year operational periods. Hybrid-ready designs permit seamless integration with solar thermal arrays, currently achieving 28% renewable fraction in pilot projects.

(gas fired boiler for commercial heating)

FAQS on gas fired boiler for commercial heating

Q: What factors should I consider when buying a commercial heating gas-fired boiler?

A: Prioritize boiler capacity, energy efficiency ratings (e.g., AFUE), compliance with local emission regulations, and after-sales support. Customization options and low nitrogen oxide (NOx) output are also key for sustainability.

Q: Can I get a custom gas-fired boiler designed for specific commercial heating needs?

A: Yes, manufacturers offer tailored solutions based on heating load, space constraints, and fuel type. Custom designs may include modular setups or low-nitrogen condensing technology for higher efficiency.

Q: Why choose a low nitrogen condensing gas-fired boiler for commercial heating?

A: Low nitrogen models reduce harmful emissions and meet strict environmental regulations. Condensing technology also improves energy efficiency by capturing waste heat, lowering operational costs.

Q: How does a custom commercial heating boiler improve energy savings?

A: Custom boilers optimize fuel usage and heat output for your facility’s needs. Features like variable-speed pumps and smart controls further enhance efficiency, reducing long-term energy expenses.

Q: What maintenance is required for a commercial gas-fired boiler?

A: Regular inspections, cleaning of heat exchangers, and checking for gas leaks are essential. For low-nitrogen condensing models, ensure condensate drainage systems are debris-free to maintain peak performance.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

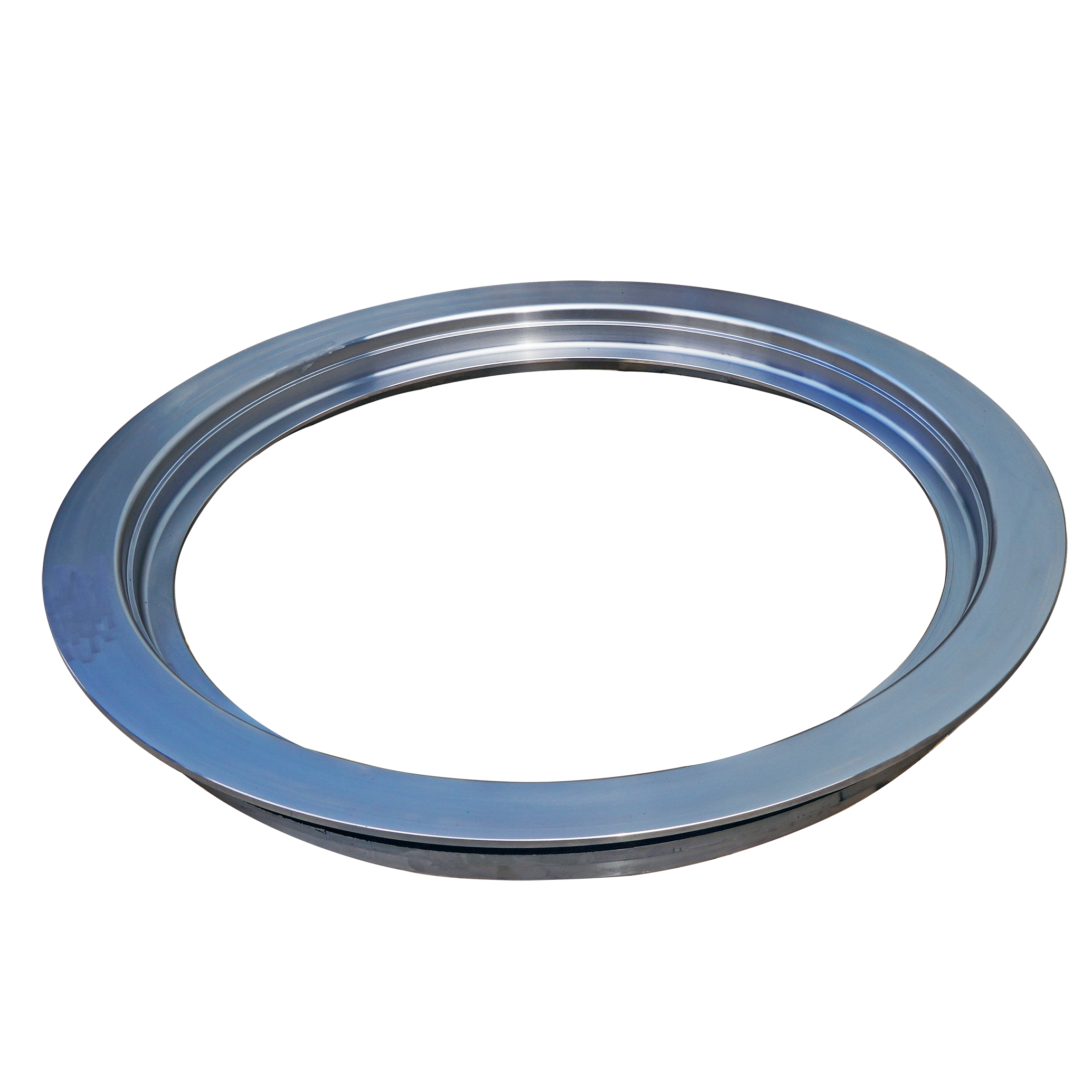

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025