Oct . 18, 2024 11:03 Back to list

ODM Concrete Pipe Mold Pallets for Efficient Construction Solutions and Durability

The Importance of ODM Concrete Pipe Mold Pallets in Construction

In the construction industry, efficient and durable materials are essential for creating strong infrastructures. One critical component in this process is the ODM (Original Design Manufacturer) concrete pipe mold pallets. These pallets play a vital role in the production of concrete pipes, which are widely used in various construction projects, including drainage systems, sewage systems, and irrigation networks.

Understanding ODM Concrete Pipe Mold Pallets

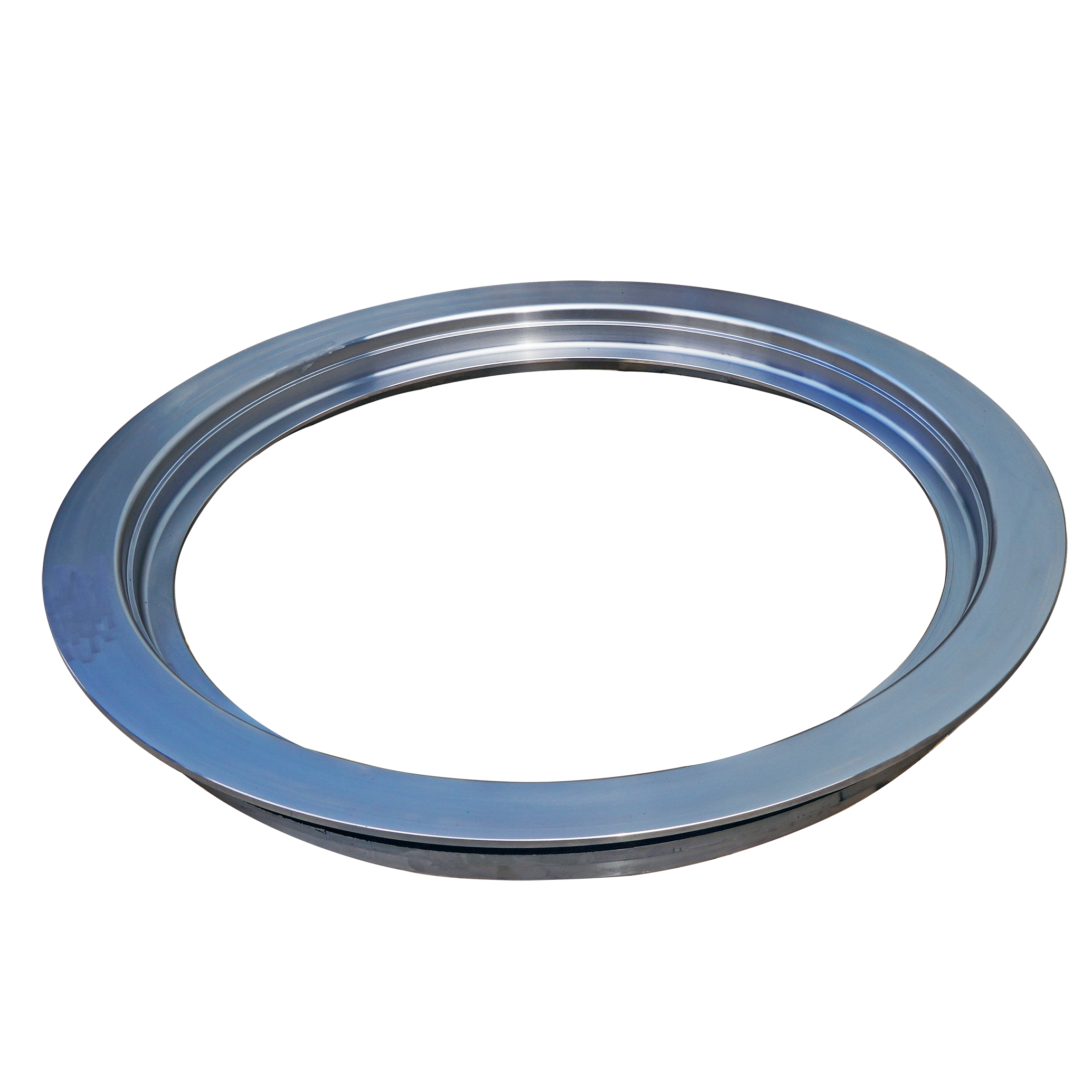

ODM concrete pipe mold pallets are specially designed molds used for shaping and forming concrete pipes during the manufacturing process. The term ODM refers to companies that produce products based on another company's specifications, ensuring that the molds meet specific requirements and standards. This collaboration allows for the creation of high-quality, precision-engineered molds that contribute to the overall quality of the concrete pipes produced.

These pallets are typically made from robust materials such as steel or high-density polyethylene (HDPE), ensuring longevity and resistance to wear and tear. The design of the mold pallets can significantly influence the properties of the finished concrete pipes, including their strength, durability, and resistance to environmental factors.

Advantages of Using ODM Concrete Pipe Mold Pallets

1. Customization One of the primary advantages of ODM concrete pipe mold pallets is their ability to be customized according to the needs of the client. Manufacturers can work closely with ODM companies to design molds that accommodate specific pipe dimensions, shapes, and technical requirements. This level of customization enhances the final product's performance and adaptability to various construction scenarios.

odm concrete pipe mold pallet

2. Cost-Effectiveness Investing in ODM concrete pipe mold pallets can lead to significant cost savings in the long run. By using high-quality molds, manufacturers can produce concrete pipes more efficiently, reducing waste and decreasing production time. Furthermore, these molds are designed for durability, meaning they can be utilized over numerous production cycles without the need for frequent replacements.

3. Improved Quality Control ODM concrete pipe mold pallets facilitate better quality control in the manufacturing process. With precise molds, manufacturers can ensure that each pipe meets specified standards for dimensions and structural integrity. This consistency is crucial in construction, where the reliability of materials directly impacts safety and longevity.

4. Enhanced Production Efficiency The use of well-designed molds streamlines the production process. Efficient mold design leads to faster curing times for concrete, meaning that the overall manufacturing cycle can be shortened. This increase in efficiency allows manufacturers to meet demand without compromising on quality.

5. Environmental Sustainability Many ODM manufacturers are now focusing on environmentally-friendly practices, including the use of recyclable materials and energy-efficient production techniques. By choosing ODM concrete pipe mold pallets that prioritize sustainability, construction companies can align with global efforts to reduce their carbon footprint.

Conclusion

In summary, ODM concrete pipe mold pallets are an essential aspect of modern construction practices. They offer a range of benefits, including customization, cost-effectiveness, improved quality control, enhanced production efficiency, and a more sustainable approach to manufacturing. As the construction industry continues to evolve, the demand for high-quality concrete pipes will grow, making the importance of ODM concrete pipe mold pallets even more pronounced. By investing in these specialized molds, manufacturers can ensure they are well-equipped to meet the challenges of today’s construction demands while maintaining the highest standards of quality and performance.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025