Nov . 09, 2024 12:13 Back to list

OEM Cast Silicon Aluminum Alloy Gas Boiler for Efficient Heating Solutions

The Evolution and Benefits of OEM Cast Silicon Aluminum Alloy Gas Fired Boilers

In recent years, the demand for energy-efficient heating solutions has risen significantly, prompting the development of advanced boiler technologies. Among the various options available in the market, OEM cast silicon aluminum alloy gas fired boilers have emerged as a leading choice for both residential and commercial applications. These boilers offer a unique combination of durability, efficiency, and environmental sustainability.

Understanding the Technology

OEM, or Original Equipment Manufacturer, cast silicon aluminum alloy refers to a specific material composition used in the production of boiler components. Silicon aluminum alloys are known for their exceptional strength-to-weight ratio and resistance to corrosion, making them ideal for high-pressure and high-temperature applications. These alloys also exhibit excellent casting properties, allowing for the production of complex shapes that optimize heat transfer and enhance overall performance.

Gas fired boilers utilizing this advanced material are designed to operate with natural gas or propane, providing an efficient and cost-effective method of heating. They are equipped with advanced combustion technology that ensures complete fuel burning, resulting in lower emissions and increased efficiency. This aspect is particularly crucial in today's environmentally conscious market, as regulations around greenhouse gas emissions are becoming increasingly stringent.

Benefits of Cast Silicon Aluminum Alloy Boilers

1. Durability One of the primary advantages of using cast silicon aluminum alloy in boiler construction is its inherent durability. The material's resistance to corrosion and wear ensures a longer lifespan for the boiler, which can substantially reduce maintenance costs over time.

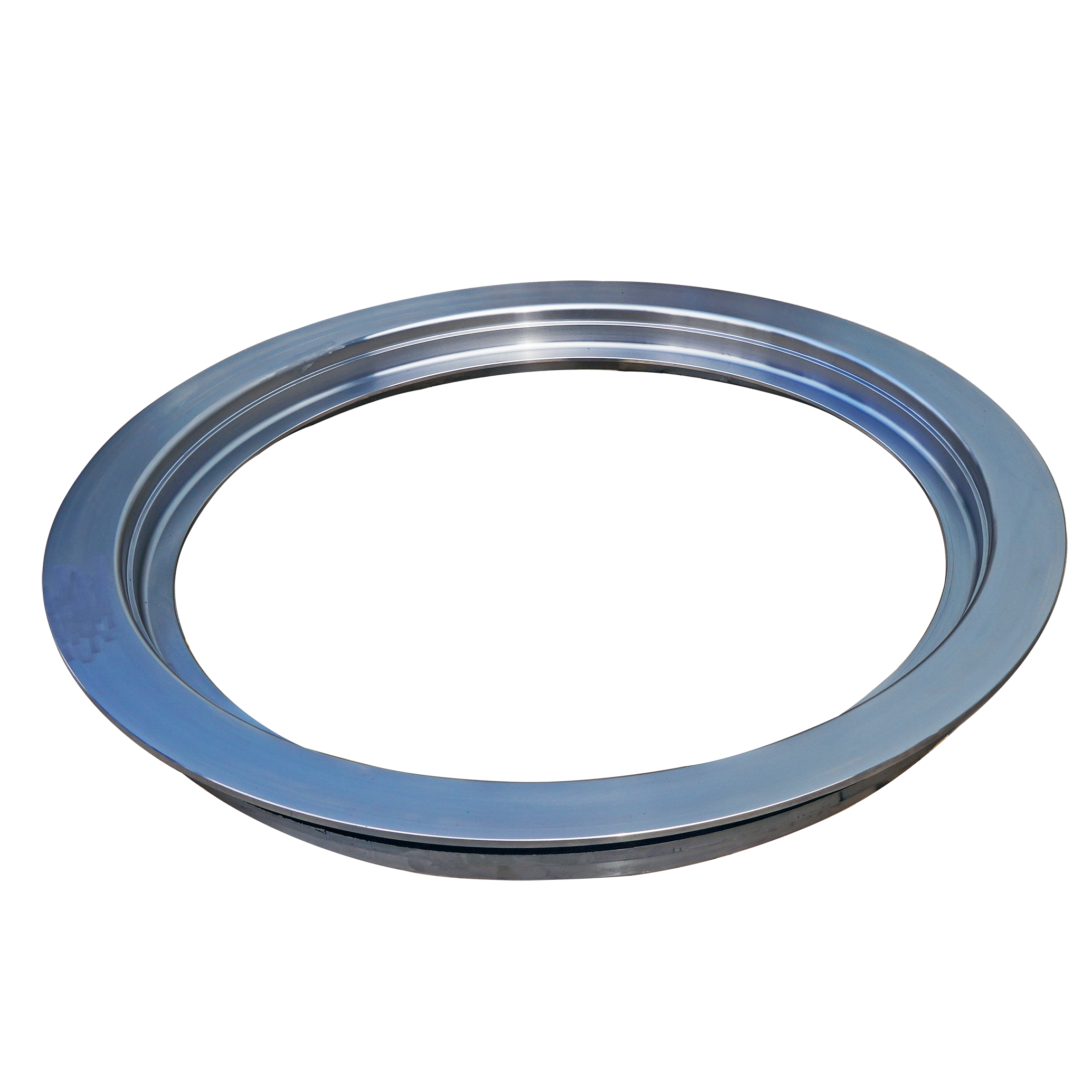

oem cast silicon aluminum alloy gas fired boiler

2. Efficiency Gas fired boilers are typically more efficient than their oil or coal counterparts. With the use of cast silicon aluminum, the heat exchange surface area can be maximized, leading to improved thermal efficiency. This translates into lower fuel consumption and reduced energy bills for users.

3. Improved Performance in Extreme Conditions These boilers perform exceptionally well in extreme weather conditions, making them a reliable choice for various climates. Their robust construction allows them to maintain efficiency and effectiveness, even in the harshest environments.

4. Lightweight Design The lightweight nature of silicon aluminum alloy makes these boilers easier to handle and install. This can lead to lower installation costs and less structural reinforcement required in buildings.

5. Low Emissions As the world moves towards greener technologies, the demand for low-emission heating solutions has increased. Gas fired boilers made from cast silicon aluminum alloy can operate at lower emission levels compared to traditional heating systems, aligning with global sustainability goals.

6. Versatility OEM cast silicon aluminum alloy boilers can be used in various applications, from residential heating systems to large industrial setups. Their adaptability makes them suitable for a wide array of heating requirements, providing flexibility to users.

Conclusion

In conclusion, OEM cast silicon aluminum alloy gas fired boilers represent a significant advancement in heating technology. They combine durability, efficiency, and environmental responsibility, making them an attractive option for those seeking reliable heating solutions. As the industry continues to evolve, these boilers are likely to play a pivotal role in meeting the challenges of energy consumption and environmental sustainability. Investing in this technology not only supports a greener environment but also contributes to long-term savings and enhanced performance in heating systems. Whether for residential use or industrial applications, the benefits of gas fired boilers made from cast silicon aluminum alloy are clear they are a smart choice for the future of heating technology.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025