Sep . 29, 2024 00:29 Back to list

OEM Heat Exchanger Solutions Tailored for Aquaculture Industry Applications

The Role of OEM Heat Exchangers in Aquaculture Operations

Aquaculture, the farming of aquatic organisms such as fish, shellfish, and plants, is an industry that has gained immense importance in recent years. With the global demand for seafood continuing to rise, it has become vital for aquaculture producers to utilize efficient technologies that promote sustainable growth. One such technology that plays a pivotal role in optimizing aquaculture operations is the OEM (Original Equipment Manufacturer) heat exchanger.

Understanding OEM Heat Exchangers

OEM heat exchangers are custom-designed heat transfer devices that meet the specific needs of various applications, including aquaculture. These specialized tools are integral in regulating water temperature within aquaculture systems, ensuring optimal growth conditions for aquatic organisms. By transferring heat to or from the water, these units maintain the ideal thermal environment, which is crucial for the health and growth of fish and other aquatic species.

Importance of Temperature Control in Aquaculture

Temperature control is a fundamental aspect of aquaculture management. Fish and other aquatic organisms are ectothermic, meaning their body temperature is regulated by the surrounding environment. Therefore, maintaining the appropriate water temperature can directly impact the metabolism, growth rates, reproduction, and overall health of these organisms. In colder climates or during winter months, the water temperature can drop significantly, stressing aquatic life and slowing growth rates. Conversely, elevated temperatures can lead to oxygen depletion and increased vulnerability to diseases.

OEM heat exchangers are designed to efficiently transfer heat in either direction, making them valuable for heating or cooling the water according to seasonal needs. This capability allows aquaculture operations to maintain consistent and optimal conditions, thereby maximizing yield and reducing mortality rates.

Customization and Efficiency

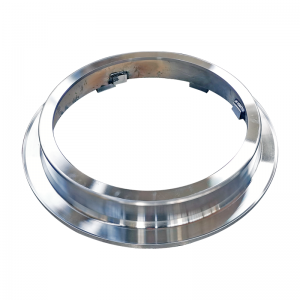

oem heat exchanger for aquaculture

One of the significant advantages of using OEM heat exchangers in aquaculture is their customizable nature. Depending on the specific requirements of an operation, these heat exchangers can be designed to cater to various flow rates, materials, and configurations. This level of customization ensures that aquaculture systems operate efficiently, optimizing not only energy use but also water quality.

Efficiency is crucial in aquaculture, where margins are often tight. An efficient heat exchanger can lead to significant cost savings, as it minimizes energy consumption while providing the necessary temperature control. This is especially important in large-scale operations or recirculating aquaculture systems, where even small changes in efficiency can result in substantial financial benefits.

Supporting Sustainability

As the aquaculture industry faces increasing pressure to adopt sustainable practices, the implementation of OEM heat exchangers can play a critical role in this transition. Efficient temperature control helps reduce energy consumption, thus lessening the carbon footprint of aquaculture practices. Additionally, by promoting healthier and more robust aquatic populations, OEM heat exchangers contribute to sustainable seafood production.

Moreover, advanced heat exchangers can facilitate the recovery of waste heat from systems, further enhancing energy efficiency. Utilizing waste heat can significantly lower the energy requirements for heating the water, making aquaculture systems more environmentally friendly and economically viable.

Conclusion

In conclusion, OEM heat exchangers represent an essential innovation in the aquaculture industry. Their ability to provide efficient, customizable, and effective temperature control allows aquaculture operations to thrive in various environmental conditions. As the demand for sustainable seafood continues to rise, the implementation of advanced technologies like OEM heat exchangers will be vital for the future of aquaculture. By embracing these innovations, aquaculture producers can enhance productivity, ensure the health of aquatic organisms, and support a more sustainable approach to food production. This not only fulfills consumer demand but also aligns with global initiatives toward responsible aquaculture practices, securing a better future for both the industry and the environment.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025