Aug . 29, 2024 17:12 Back to list

Premium Punch Cement Pipe Mold Pallets Manufacturer | Durable & Custom Solutions

The Evolution of Punch Cement Pipe Mold Pallet Manufacturing

In the construction industry, the quality and durability of infrastructure are paramount. This is where the innovation of punch cement pipe molds and pallets comes into play, offering an efficient and reliable solution for producing high-quality cement pipes. As the demand for infrastructure grows, so does the necessity for sophisticated manufacturing techniques. This article explores the importance of punch cement pipe mold pallets and their impact on the industry.

Cement pipes are essential for various applications, including sewage systems, water supply, and drainage. The ability to manufacture these pipes efficiently and with high precision has led to advancements in mold technology, with punch molds offering significant benefits. They are specifically designed to create pipes with intricate internal and external shapes, enhancing their functionality and performance.

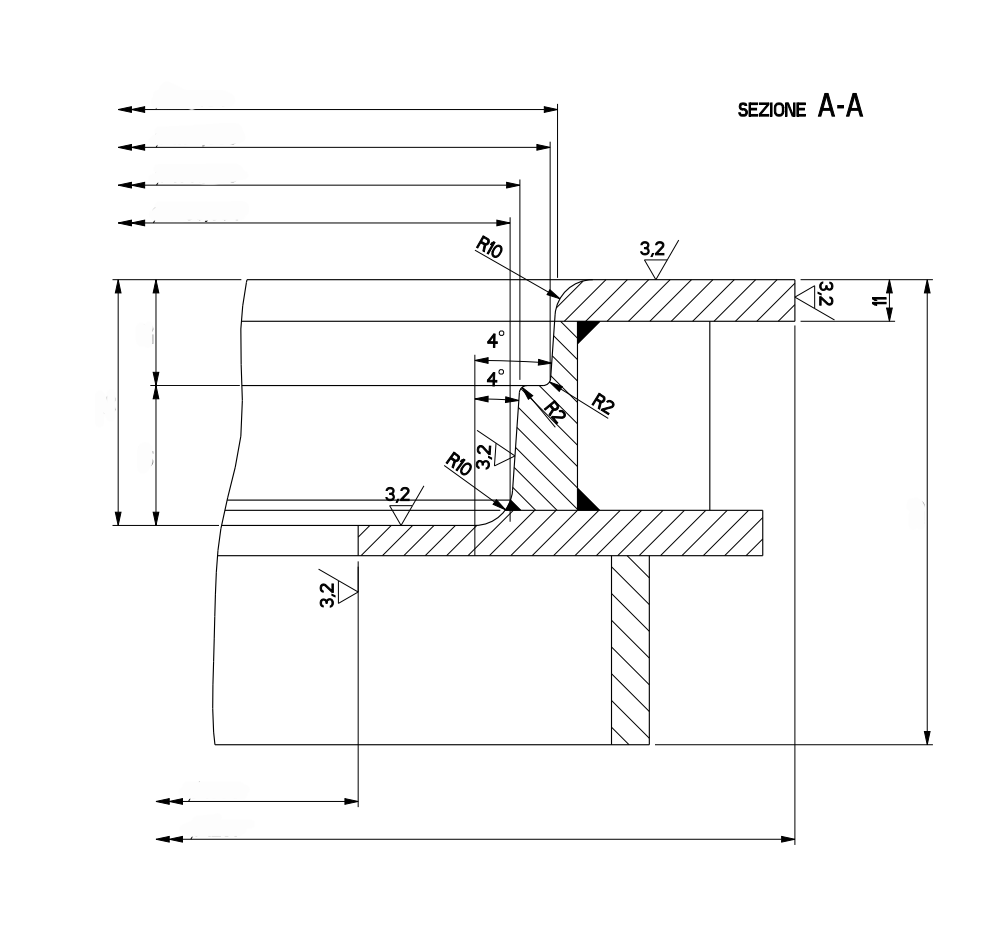

The process of creating a punch cement pipe mold involves the careful design of the mold structure. Manufacturers leverage advanced materials and engineering techniques to ensure that the molds are durable and can withstand the rigors of repeated use. A robust mold design not only ensures higher-quality output but also reduces production costs by minimizing wear and tear.

Pallets play a crucial role in the transportation and handling of cement pipes. A high-quality mold pallet must have the ability to support the weight of the finished pipes while providing stability during the curing process. Many manufacturers have adopted innovative pallet designs that incorporate features such as lightweight materials and ergonomic shapes for easier handling. These enhancements significantly improve efficiency and safety in manufacturing environments.

punch cement pipe mold pallet manufacturer

Another pivotal aspect of punch cement pipe mold pallet manufacturing is the integration of automation and technology. Many manufacturers have embraced automated systems to streamline the production process. Automated machinery can accurately position molds, optimize vibration during casting, and efficiently handle cured products. This not only enhances productivity but also ensures consistency in the quality of the finished pipes.

Environmental considerations have also become a focus in the production of cement pipe molds and pallets. Manufacturers are increasingly looking to incorporate sustainable practices, such as using eco-friendly materials and reducing waste during production. Innovations in recycling and reusing materials are paving the way for a greener approach to cement pipe manufacturing, aligning with global trends toward sustainability.

Moreover, collaboration with research institutions and universities is fostering innovation in mold design and manufacturing processes. This cooperation allows manufacturers to stay ahead of industry trends and adopt the latest technological advancements, ensuring they remain competitive in a rapidly evolving market.

In conclusion, the significance of punch cement pipe mold pallets cannot be overstated. They are essential in enhancing the efficiency and quality of cement pipe production. With a focus on durability, automation, and sustainability, manufacturers are poised to meet the growing demand for infrastructure while maintaining high standards of quality and environmental responsibility. As the construction industry continues to adapt and innovate, the evolution of mold and pallet technology will undoubtedly play a crucial role in shaping the future of cement pipe manufacturing.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025