Jun . 24, 2024 02:53 Back to list

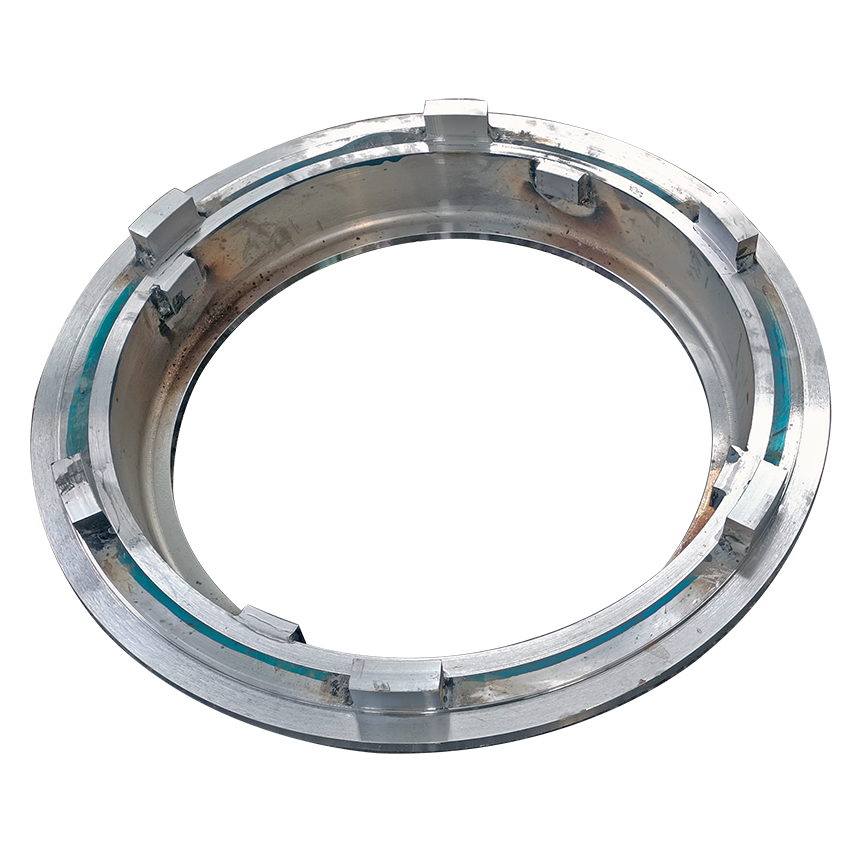

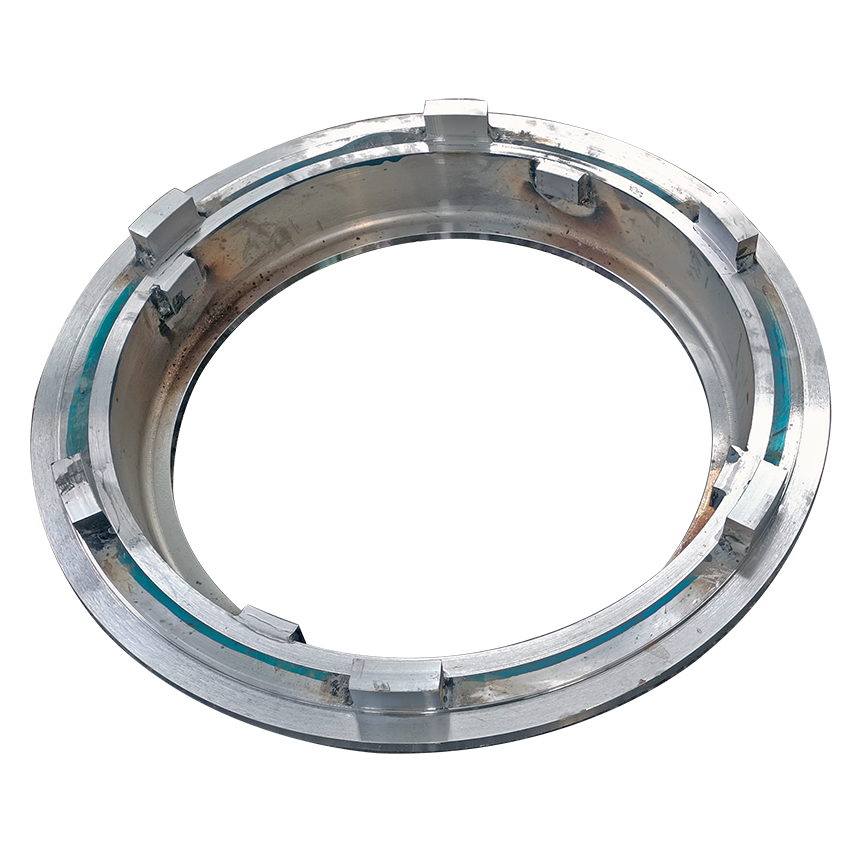

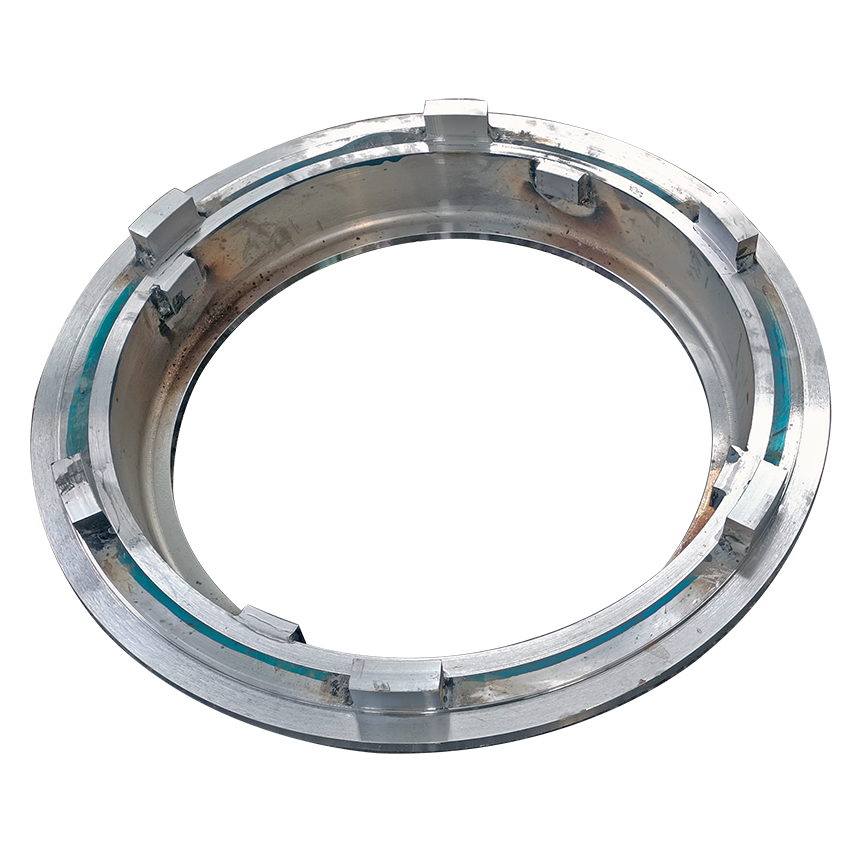

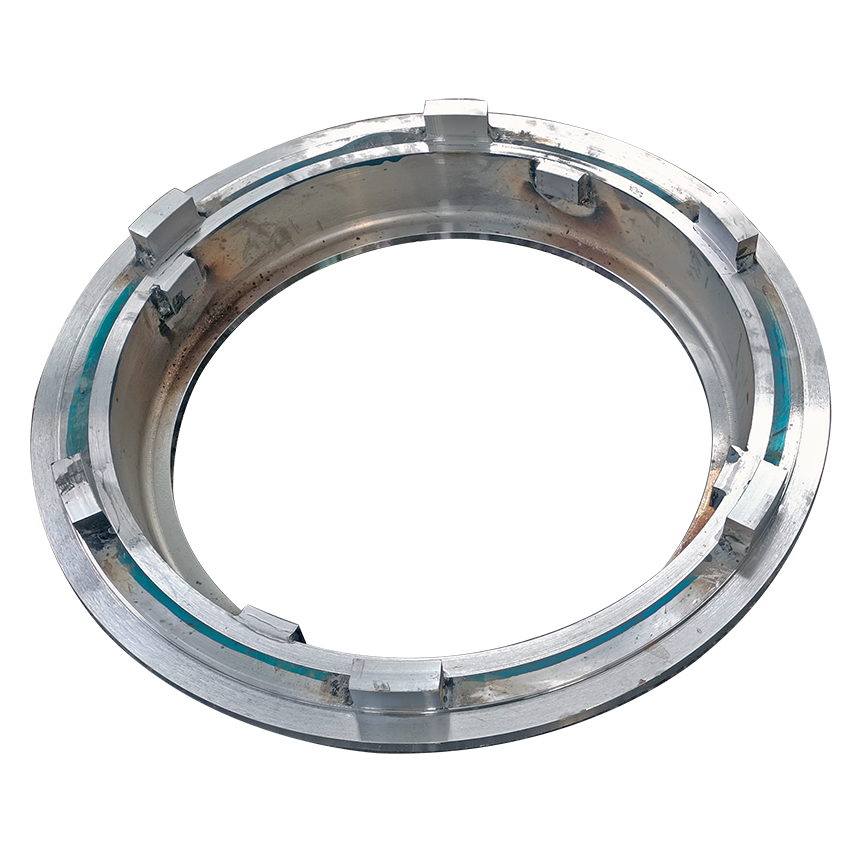

Reinforced Concrete Pipe Mold Ring Bottom

Innovations in Reinforced Concrete Pipe Mold Bottom Ring Design

The production of reinforced concrete pipes is a crucial process for various infrastructure projects, from sewage systems to water supply networks. A key component in this process is the pipe mold, particularly the bottom ring of the mold, which ensures the stability and quality of the finished product. Innovative designs in reinforced concrete/cement pipe mold bottom rings have significantly improved the efficiency and effectiveness of pipe production.

Traditionally, bottom rings were designed simply to provide a flat, stable base for the concrete to be poured into. However, with advancements in engineering and materials science, modern bottom rings incorporate features that enhance their performance and longevity. For instance, the inclusion of adjustable supports allows for precise leveling of the mold, ensuring that the pipe walls are of uniform thickness. This not only extends the lifespan of the pipe but also maintains its structural integrity under pressure.

Another innovation is the use of high-strength, corrosion-resistant materials for the bottom ring construction. These materials can withstand the harsh chemicals often present in sewage and water systems, reducing maintenance requirements and prolonging the service life of the molds. Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete

Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete reinforced concrete/cement pipe mold/mould bottom ring. Proper temperature control during the curing phase is essential for developing the optimal strength and durability of the concrete, thus improving the overall quality of the pipe.

Ergonomic improvements have also been made to bottom ring designs, with handles and locking mechanisms made more user-friendly to facilitate easier assembly and disassembly. This not only speeds up the production process but also reduces the risk of worker injury. Additionally, modular components that allow for quick replacement of worn parts without the need to replace the entire bottom ring save costs and reduce downtime.

In conclusion, the evolution of reinforced concrete/cement pipe mold bottom ring design has greatly contributed to the enhancement of pipe manufacturing processes. By integrating features that improve stability, durability, and ease of use, these innovations ensure that the pipes produced are of superior quality and can reliably serve their intended purposes for many years. As technology continues to advance, it is likely that we will see further improvements in this critical component of infrastructure development.

reinforced concrete/cement pipe mold/mould bottom ring. Proper temperature control during the curing phase is essential for developing the optimal strength and durability of the concrete, thus improving the overall quality of the pipe.

Ergonomic improvements have also been made to bottom ring designs, with handles and locking mechanisms made more user-friendly to facilitate easier assembly and disassembly. This not only speeds up the production process but also reduces the risk of worker injury. Additionally, modular components that allow for quick replacement of worn parts without the need to replace the entire bottom ring save costs and reduce downtime.

In conclusion, the evolution of reinforced concrete/cement pipe mold bottom ring design has greatly contributed to the enhancement of pipe manufacturing processes. By integrating features that improve stability, durability, and ease of use, these innovations ensure that the pipes produced are of superior quality and can reliably serve their intended purposes for many years. As technology continues to advance, it is likely that we will see further improvements in this critical component of infrastructure development.

Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete

Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete Furthermore, some designs include integrated heating elements that help regulate the curing temperature of the concrete reinforced concrete/cement pipe mold/mould bottom ring. Proper temperature control during the curing phase is essential for developing the optimal strength and durability of the concrete, thus improving the overall quality of the pipe.

Ergonomic improvements have also been made to bottom ring designs, with handles and locking mechanisms made more user-friendly to facilitate easier assembly and disassembly. This not only speeds up the production process but also reduces the risk of worker injury. Additionally, modular components that allow for quick replacement of worn parts without the need to replace the entire bottom ring save costs and reduce downtime.

In conclusion, the evolution of reinforced concrete/cement pipe mold bottom ring design has greatly contributed to the enhancement of pipe manufacturing processes. By integrating features that improve stability, durability, and ease of use, these innovations ensure that the pipes produced are of superior quality and can reliably serve their intended purposes for many years. As technology continues to advance, it is likely that we will see further improvements in this critical component of infrastructure development.

reinforced concrete/cement pipe mold/mould bottom ring. Proper temperature control during the curing phase is essential for developing the optimal strength and durability of the concrete, thus improving the overall quality of the pipe.

Ergonomic improvements have also been made to bottom ring designs, with handles and locking mechanisms made more user-friendly to facilitate easier assembly and disassembly. This not only speeds up the production process but also reduces the risk of worker injury. Additionally, modular components that allow for quick replacement of worn parts without the need to replace the entire bottom ring save costs and reduce downtime.

In conclusion, the evolution of reinforced concrete/cement pipe mold bottom ring design has greatly contributed to the enhancement of pipe manufacturing processes. By integrating features that improve stability, durability, and ease of use, these innovations ensure that the pipes produced are of superior quality and can reliably serve their intended purposes for many years. As technology continues to advance, it is likely that we will see further improvements in this critical component of infrastructure development. Share

Latest news

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025