Nov . 10, 2024 06:49 Back to list

Manufacturers of Stamped Concrete Pipe Moulds and Base Rings for Efficient Production

The Role of Stamp Concrete Pipe Mould Bottom Ring Factories in Modern Infrastructure

In the ever-evolving landscape of construction and infrastructure development, the significance of concrete pipes cannot be overstated. They are essential components for drainage systems, sewerage management, and urban water supply networks. Key to the production of these concrete pipes are the factories specializing in the manufacture of stamp concrete pipe mould bottom rings. These factories play a crucial role in ensuring the efficiency, durability, and reliability of the products used in infrastructure projects.

Understanding Concrete Pipe Manufacturing

Concrete pipes are created through a meticulous process involving the formulation of concrete mixtures, molding, curing, and finishing. The bottom ring of the pipe mould is particularly significant, as it shapes the first segment of the pipe, setting the foundation for the rest of the manufacturing process. The bottom ring must be designed for optimal strength and precision to ensure a perfect fit during assembly and a seamless flow of materials throughout the pipe.

Stamp concrete pipe mould bottom ring factories employ advanced techniques and technologies to create these essential components. The use of stamping processes allows for increased efficiency and uniformity in the production line. High-quality moulds are engineered to withstand high pressures and abrasive materials, thus ensuring a long lifespan for the concrete pipes produced.

Importance of Quality Control

In the manufacturing of concrete pipe mould bottom rings, quality control is paramount. Factories must adhere to stringent standards to ensure that each mould meets the specifications required for the intended use. This includes conducting rigorous testing on materials and finished products, including pressure tests, durability assessments, and dimensional accuracy checks. By implementing such quality assurance measures, factories can guarantee that their moulds will produce pipes capable of withstanding the rigors of environmental and operational stresses.

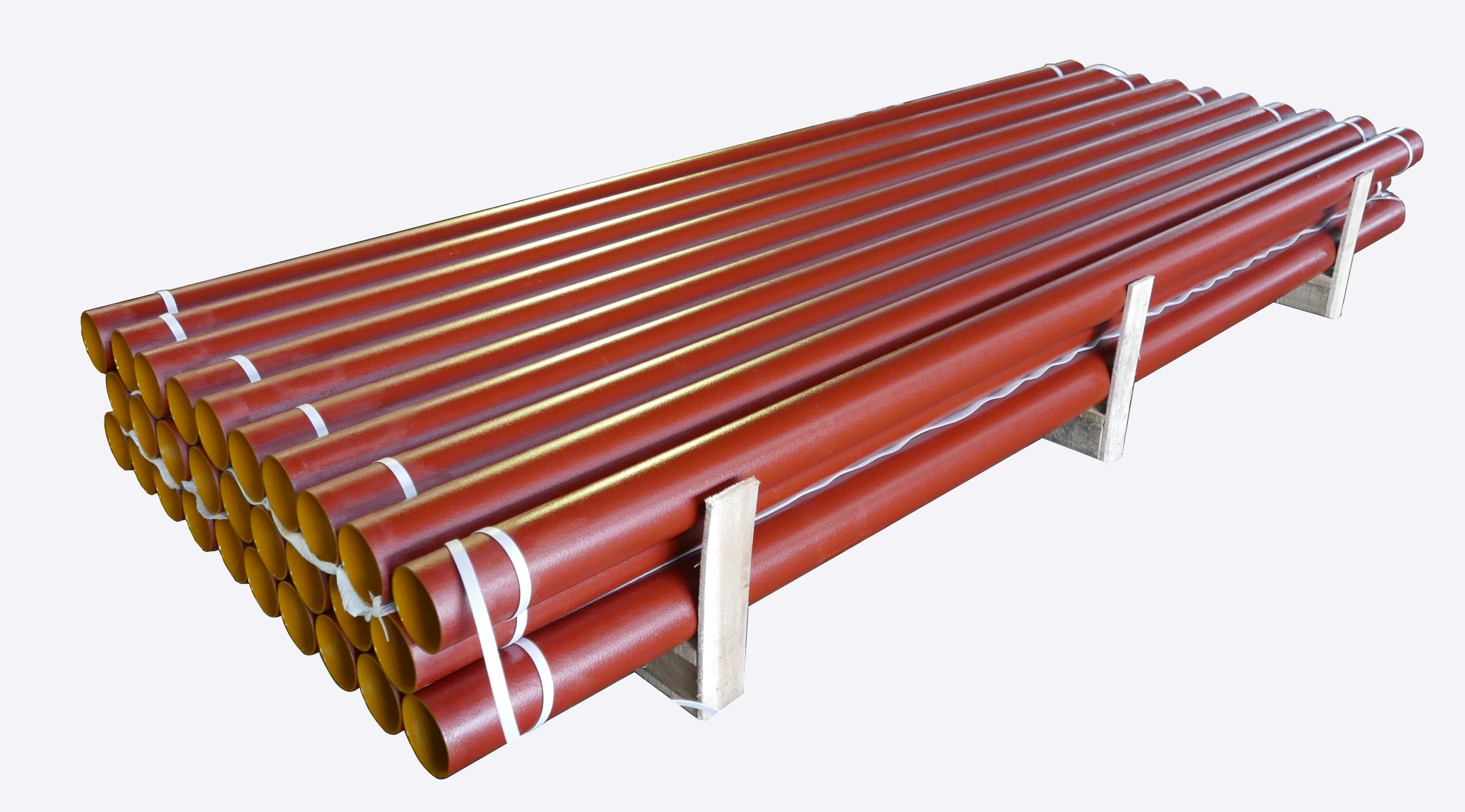

stamp concrete pipe mould bottom ring factories

Additionally, environmental considerations have become increasingly important in recent years. Factories are now focusing on sustainable practices, using eco-friendly materials wherever possible and optimizing processes to minimize waste. This commitment to sustainability not only helps protect the environment but also enhances the reputability of the manufacturers in a competitive market.

Customization and Innovation

As infrastructure projects become more specialized and tailored to particular needs, the demand for customized concrete pipe mould bottom rings has increased. Leading factories are investing in research and development to create innovative solutions that cater to the specific requirements of their clients. This might include adjustable moulds that can produce different diameters or profiles of pipes, allowing for greater flexibility in construction.

Moreover, advancements in technology, such as 3D printing and computer-aided design (CAD), are revolutionizing the way these factories operate. By utilizing these technologies, manufacturers can produce high-precision moulds more quickly and accurately than traditional methods would allow. This speeds up production times and reduces costs, ultimately benefiting clients and end-users.

Conclusion

Stamp concrete pipe mould bottom ring factories are instrumental in facilitating the construction of robust, high-quality concrete pipes that are vital for modern infrastructure. Through their commitment to quality control, sustainable practices, and innovation, these factories not only produce essential components but also contribute to the overall efficiency and effectiveness of urban development projects. As the demand for reliable infrastructure continues to grow worldwide, the importance of these factories will only increase, solidifying their role in shaping the future of construction. The next time you see a concrete pipe, remember that the foundation of its quality starts with the mould and the expertise of the manufacturers behind it.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025