Oct . 13, 2024 09:41 Back to list

Concrete Pipe Mold Bottom Ring Manufacturer for Stamping Innovative Solutions

The Importance of Stamping Concrete Pipe Mold Bottom Rings An Insight into Manufacturing

In the realm of construction and civil engineering, the demand for high-quality materials is paramount. Among these materials, concrete pipes play a crucial role, especially in drainage systems, sewer lines, and various infrastructure projects. One of the key components in the production of concrete pipes is the bottom ring of the molds used to shape them. This article aims to delve into the significance of stamping concrete pipe mold bottom rings and shed light on the manufacturing processes involved.

Understanding Concrete Pipe Mold Bottom Rings

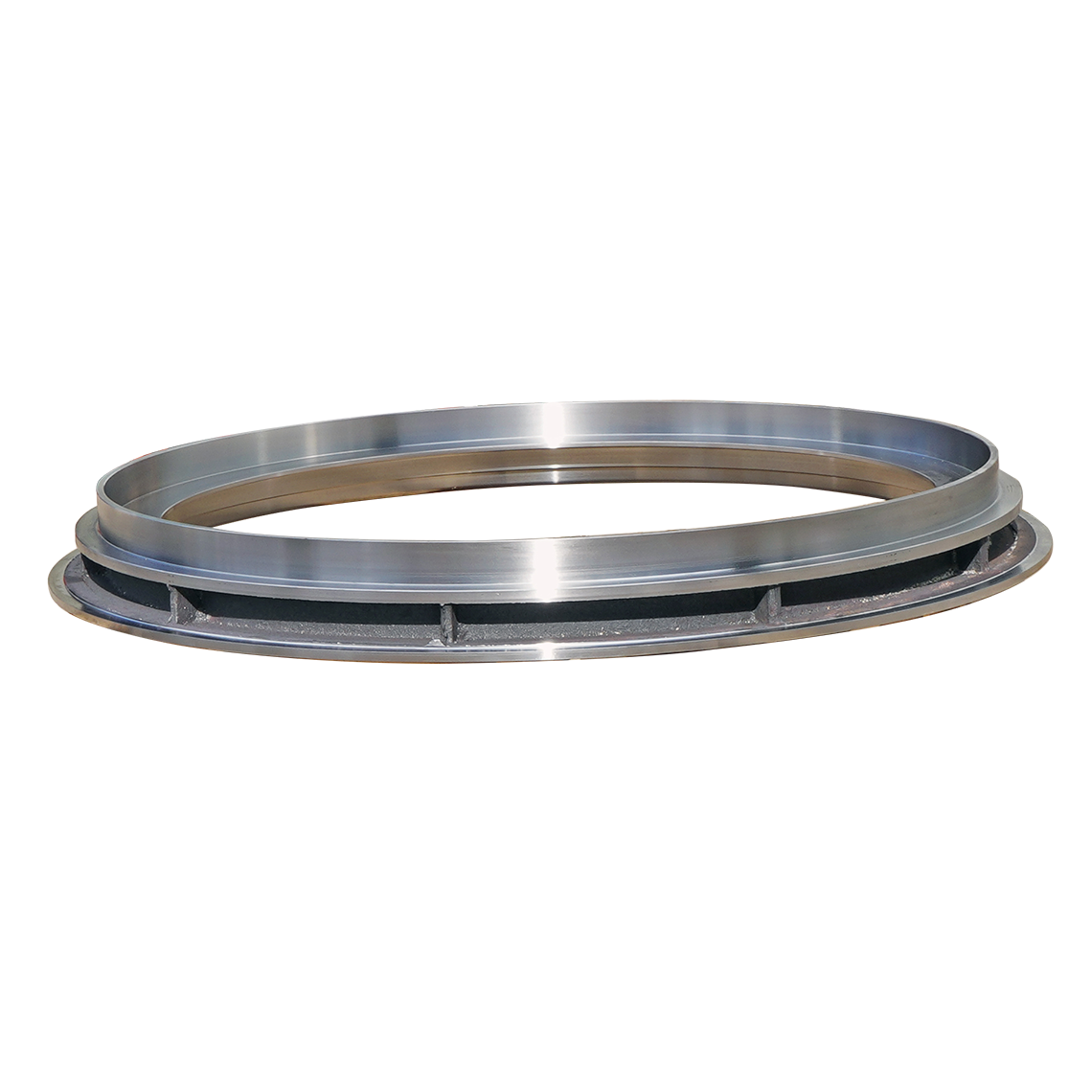

Concrete pipe mold bottom rings serve as foundational components in the production of concrete pipes. These rings are usually made of high-strength materials to withstand the pressure and wear associated with the concrete curing process. They play a vital role in ensuring that the concrete achieves the desired shape and structural integrity.

The bottom ring is typically stamped, allowing for high accuracy in dimensions and consistency in production. Stamping involves pressing a shape into a flat sheet of material, ensuring each ring produced adheres to strict specifications while maintaining uniformity across large batches.

The Manufacturing Process

The manufacturing of stamping concrete pipe mold bottom rings involves several steps

1. Design and Prototyping The process begins with the design phase, where engineers create precise blueprints for the bottom rings. Advanced computer-aided design (CAD) software is often employed to visualize and tweak the design before any physical production begins.

2. Material Selection High-quality metals or alloys are selected for the stamping process, balancing strength and durability with cost-effectiveness. The choice of material is crucial as it influences the longevity of the molds and the quality of the pipes produced.

3. Stamping Process The selected material is then subjected to a stamping process. Using a hydraulic press, the material is cut and shaped into the desired form of the bottom ring. This method not only ensures high precision but also allows for mass production, which is essential for meeting industry demands.

stamping concrete pipe mold bottom ring manufacturer

4. Quality Control After stamping, each ring undergoes rigorous quality control checks. This includes dimensional inspections and strength tests to ensure that they meet the required standards. Any defects found at this stage lead to rejections, maintaining a high standard of quality for the final product.

5. Surface Treatment Often, the bottom rings are subjected to surface treatments to enhance their resistance to environmental factors and wear. Coatings may be applied to improve durability and extend the lifespan of the molds.

6. Final Assembly and Distribution Once the rings have passed all quality checks and treatments, they are assembled into the full mold systems. These molds are then distributed to concrete manufacturers who will use them to produce concrete pipes.

Significance in the Industry

The use of stamping concrete pipe mold bottom rings is beneficial for several reasons

- Cost Efficiency The stamping process allows for the production of large volumes of rings in less time and with reduced labor costs, making it a cost-effective solution for manufacturers. - Consistency Stamped rings exhibit uniformity in size and shape, ensuring that the concrete pipes produced are of consistent quality. This uniformity is crucial for structural integrity in applications such as stormwater drainage and sewage systems.

- Durability High-quality stamped rings can withstand significant pressure during the concrete curing process, leading to longer-lasting pipe products.

- Innovation and Customization Manufacturers can easily modify the designs of the bottom rings to adapt to specific project requirements, embracing innovation in the construction industry.

Conclusion

The manufacturing of stamping concrete pipe mold bottom rings is a sophisticated process that plays a pivotal role in the quality and efficiency of concrete pipe production. As infrastructure needs escalate globally, the importance of these components and the technologies behind their production cannot be overstated. With advancements in manufacturing techniques and material sciences, the concrete industry is poised for continued growth and improvement, driven by the ever-evolving requirements of modern civil engineering projects.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025