Dec . 07, 2024 09:40 Back to list

steel reinforced concrete pipe mold bottom ring supplier

The Role of Steel Reinforced Concrete Pipe Mold Bottom Rings

In the construction and infrastructure sector, providing durable and reliable materials is crucial for the success of any project. Steel reinforced concrete pipes (SRCP) represent a significant advancement in pipe technology, primarily used for water and wastewater management systems. A vital component in the manufacturing of these pipes is the bottom ring mold, which holds substantial significance in determining the quality and efficacy of the final product. This article delves into the importance of the bottom ring as well as highlights the role of suppliers in the production system.

Understanding Steel Reinforced Concrete Pipes

Steel reinforced concrete pipes are popular due to their impressive load-bearing capacity, resistance to environmental degradation, and overall durability. They are typically used for stormwater drainage, sewage transportation, and various industrial applications. The added steel reinforcement significantly enhances the tensile strength of the concrete, making it suitable for heavy-duty performance.

The Importance of the Bottom Ring Mold

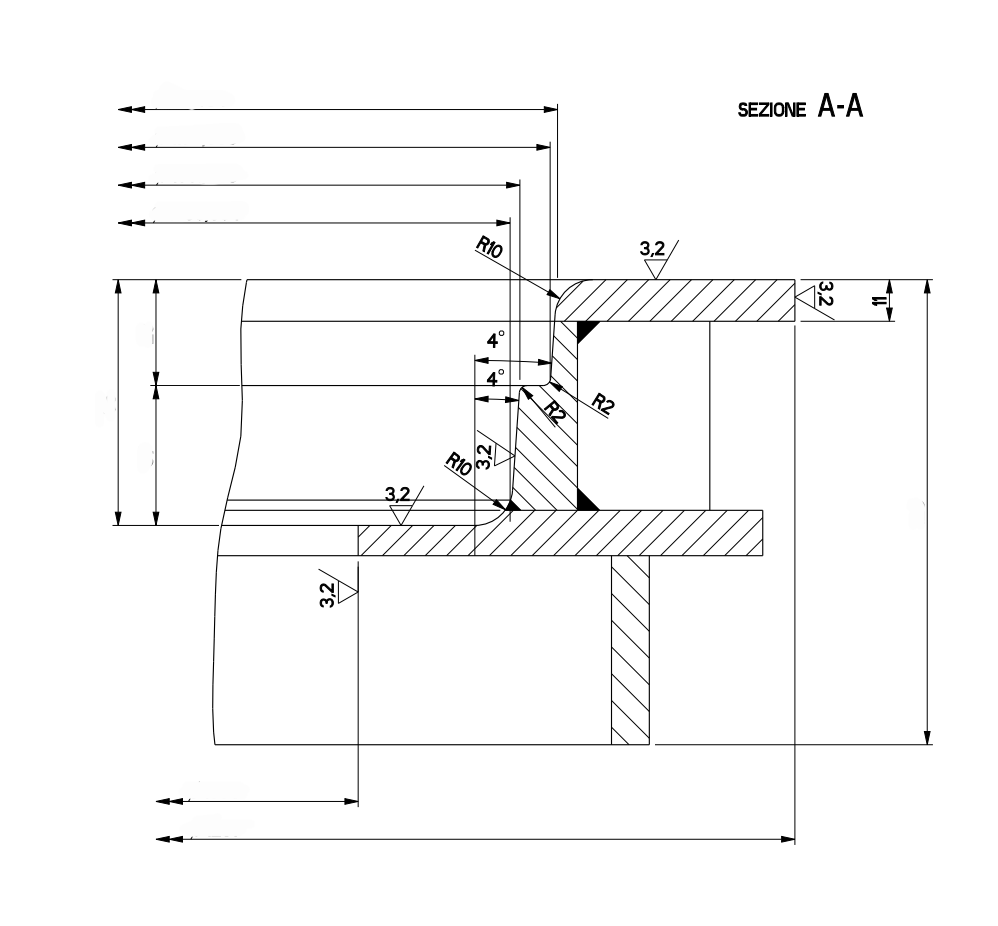

The bottom ring mold is crucial in the manufacturing process of SRCP. This mold serves as the foundation of the pipe, ensuring that it retains its shape and structural integrity during the curing process. The bottom ring molds are designed to withstand the heavy weight of wet concrete while facilitating the accurate formation of the pipe's cross-section.

1. Shape and Dimension Precision The bottom ring mold is engineered to create precise dimensions for the pipes. This precision is essential, as any discrepancy can lead to installation challenges, decreased performance, and potential failure in the field.

2. Weight Distribution Proper design of the bottom ring allows for an even distribution of weight, ensuring that the pipe can support heavy loads once installed underground. This minimizes the risk of collapse, particularly in high-traffic areas.

3. Quality Assurance Molds that are well-manufactured contribute to the overall quality of the pipe. A robust bottom ring mold ensures that the cured concrete maintains the required structural properties while minimizing defects that affect performance.

steel reinforced concrete pipe mold bottom ring supplier

Choosing a Supplier for Bottom Ring Molds

Given the critical role that the bottom ring molds play in the production of SRCP, selecting the right supplier is of paramount importance. Here are some factors to consider when choosing a supplier

1. Quality of Materials The supplier should use high-quality materials for mold production. This ensures durability and longevity, reducing the need for frequent replacements and associated costs.

2. Customization Options Different projects may require specific mold designs to meet unique requirements. A good supplier will offer customization options to cater to varying sizes and shapes based on the project needs.

3. Reputation and Experience An established supplier with a strong reputation in the industry is often a reliable choice. Their experience can contribute to better product knowledge, customer service, and potentially, more innovative solutions.

4. Cost Efficiency While quality should be the priority, cost considerations cannot be ignored. Suppliers that offer competitive pricing while maintaining high standards are ideal partners.

5. After-Sales Support Comprehensive after-sales support is essential. This includes installation guidance, maintenance tips, and a responsive customer service team that can address any issues post-purchase.

Conclusion

The importance of steel reinforced concrete pipe mold bottom rings cannot be overlooked in the construction of SRCP. They play a fundamental role in ensuring the pipes are made to uphold the rigorous demands of their applications. Choosing the right supplier who can offer quality molds, customization, and reliable support is key to ensuring the overall success of any water or wastewater infrastructure project. By investing in high-quality molds and working with reputable suppliers, construction companies can significantly enhance the reliability and durability of their pipeline systems, ultimately leading to safer and more efficient infrastructure.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025