Aug . 12, 2024 11:52 Back to list

Top Heat Exchanger Manufacturers and Suppliers in South Africa for Industrial Applications

Heat Exchanger Manufacturers in South Africa A Growing Industry

The need for efficient thermal management systems is becoming increasingly essential across various industries, and heat exchangers play a pivotal role in achieving this efficiency. In South Africa, the manufacturing sector has witnessed significant growth in the production of heat exchangers, driven by the energy demands of industries such as power generation, mining, petrochemicals, and HVAC (heating, ventilation, and air conditioning). South African heat exchanger manufacturers are not only meeting local needs but are also positioning themselves as key players in international markets.

Overview of the Heat Exchanger Market

Heat exchangers are devices that facilitate the transfer of heat between two or more fluids at different temperatures. They are crucial in numerous applications, including cooling systems, boilers, and chemical processing. The demand for heat exchangers in South Africa has increased owing to the expansion of infrastructure projects, growth in renewable energy initiatives, and the need for energy-efficient solutions amidst rising energy costs.

Key Manufacturers in South Africa

Several manufacturers in South Africa specialize in the design and production of heat exchangers. Notable companies include

1. Babcock & Wilcox Known for their extensive experience in power generation, they manufacture a range of heat exchangers tailored for energy applications. Their innovative designs improve efficiency and reliability in thermal processes.

2. Aqua-Chem Specializing in water treatment and heat exchange systems, Aqua-Chem provides customized solutions for various industries. Their commitment to quality and innovation has made them a leader in the sector.

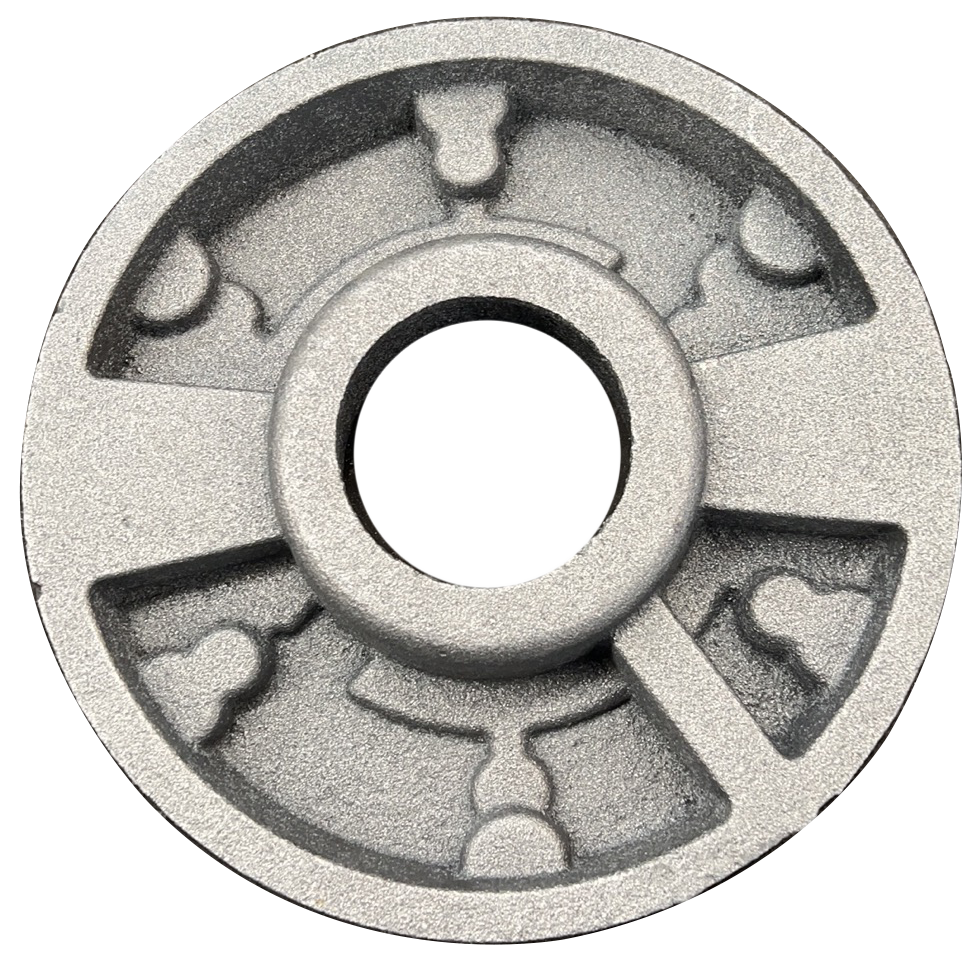

heat exchanger manufacturers in south africa

3. Stalcor As a distributor of stainless steel products, Stalcor plays a crucial role in the fabrication of heat exchangers. They supply high-quality materials that enhance the performance and longevity of heat exchangers.

4. Smart Heat This company focuses on energy-efficient heat exchanger designs that cater to diverse applications, from automotive to process industries. Their dedication to sustainability resonates well with the current global push for greener solutions.

Technological Advancements

The landscape of heat exchanger manufacturing in South Africa is evolving, with companies investing in advanced technologies. Innovations such as computer-aided design (CAD) and computational fluid dynamics (CFD) enable manufacturers to optimize designs for enhanced thermal performance and reduced material costs. Additionally, the advent of modular heat exchangers has introduced flexibility in system design, allowing for easier maintenance and scalability.

Challenges and Opportunities

Despite the growth potential, South African heat exchanger manufacturers face challenges, including competition from international producers, fluctuating raw material prices, and the need for skilled labor. However, these challenges also present opportunities for growth. By focusing on research and development, manufacturers can create innovative products that cater to specific industry needs. Furthermore, the growing emphasis on sustainable practices opens avenues for the development of eco-friendly heat exchangers that minimize energy usage and reduce carbon footprints.

Conclusion

The heat exchanger manufacturing industry in South Africa is poised for growth, driven by technological advancements and increasing demand across various sectors. As manufacturers continue to innovate and adapt to market changes, they are likely to enhance their competitiveness on a global scale. By embracing sustainability and focusing on quality, South African heat exchanger manufacturers can carve out a significant niche in the international market, contributing to a greener, more energy-efficient future. As industries evolve, the importance of effective heat transfer solutions will remain paramount, making this sector an exciting arena for both established and emerging players.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025