Oct . 17, 2024 00:00 Back to list

tube count heat exchanger

Understanding Tube Count in Heat Exchangers

Heat exchangers play a crucial role in various industries by facilitating the transfer of heat between two or more fluids. They find applications in power generation, refrigeration, chemical processing, and many other fields. One of the fundamental design parameters of a heat exchanger is its tube count, which significantly affects the unit's performance, efficiency, and overall effectiveness. This article will delve into the importance of tube count in heat exchangers and its impact on thermal performance and operational efficiency.

What is Tube Count?

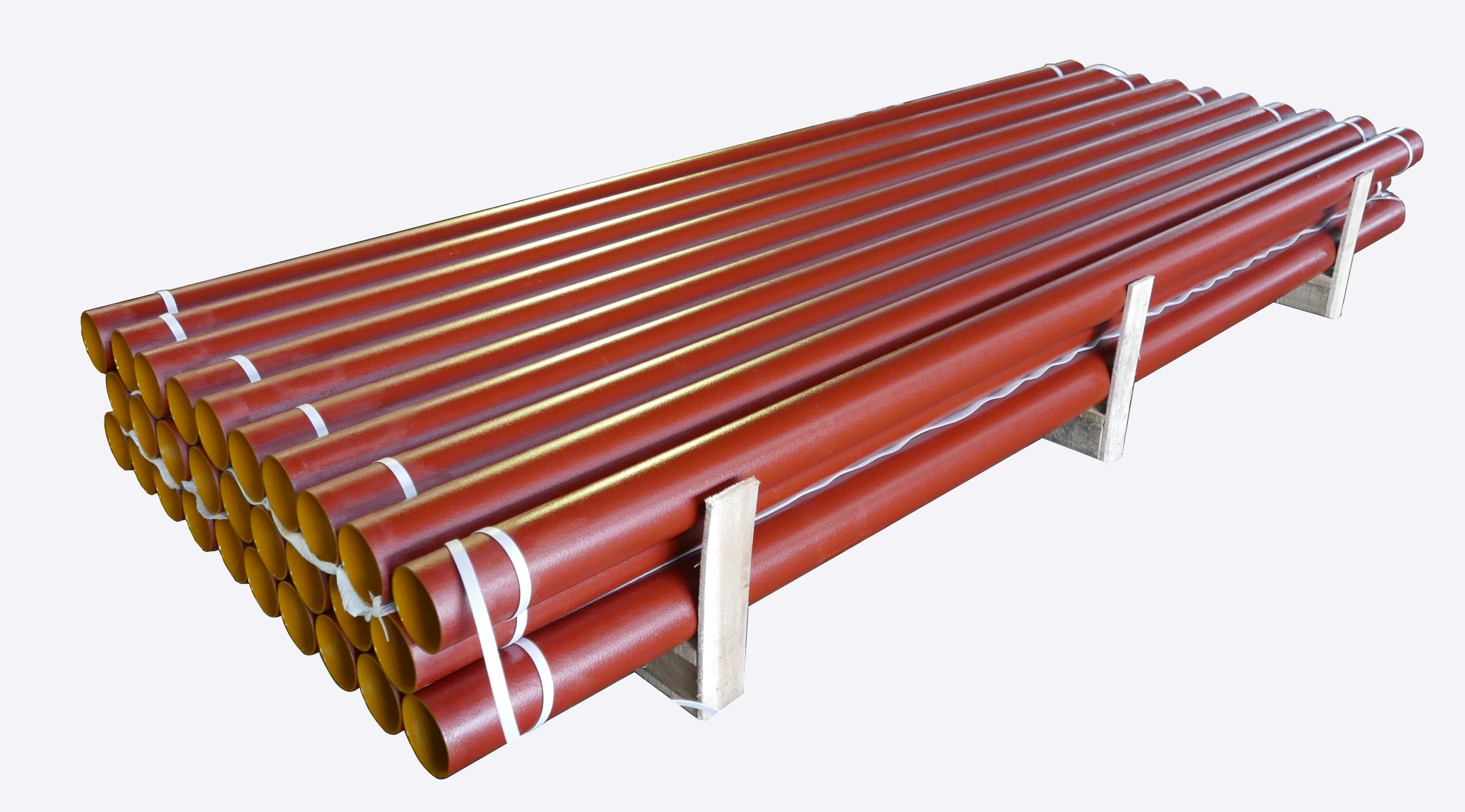

The term “tube count” refers to the number of tubes in a heat exchanger. These tubes are the conduits through which the fluids flow, allowing for the exchange of thermal energy. In most heat exchangers, particularly shell-and-tube designs, the tube count can vary widely depending on the application requirements, size of the unit, and desired heat transfer areas.

The Role of Tube Count in Performance

1. Heat Transfer Efficiency The primary function of a heat exchanger is to transfer heat from one medium to another. Increasing the number of tubes generally enhances the surface area available for heat exchange. More surface area typically means better heat transfer efficiency—especially in cases where one fluid is significantly hotter or cooler than its counterpart. However, there are diminishing returns, and after a certain point, adding more tubes may not result in proportional gains in heat transfer efficiency.

2. Pressure Drop Considerations While increasing the number of tubes can enhance heat transfer, it also affects the pressure drop across the unit. Each tube introduces resistance to fluid flow, so a higher tube count can lead to a more significant pressure drop. This increase in pressure drop can necessitate more powerful pumps to maintain the required flow rates, potentially increasing operational costs. Therefore, it is essential to strike a balance between adequate tube count for effective heat transfer and acceptable pressure drop levels.

3. Fluid Velocity The tube count also influences the velocity of the fluids running through the heat exchanger. A higher number of tubes can result in lower velocities if the total flow rate remains constant, which might lead to less effective heat transfer. Conversely, fewer tubes allow for higher fluid velocities, improving turbulence and enhancing the heat transfer rate.

tube count heat exchanger

Tube Count and Design Considerations

When designing a heat exchanger, engineers must consider various factors related to tube count, including

- Application Requirements Different applications will have different thermal and fluid flow requirements that dictate the optimal tube count. For instance, a power plant’s heat exchanger may need a very different configuration than that of a chemical processing facility.

- Size and Footprint The physical size of the heat exchanger can limit the number of tubes that can feasibly be installed. Space constraints may lead engineers to design a heat exchanger with fewer tubes or to choose a different style altogether, such as plate heat exchangers, which provide a larger surface area in a more compact form.

- Material Compatibility and Cost The materials used for the tubes can also influence the design. Tubes must withstand the specific pressures and temperatures of the fluids they accommodate, and different materials come with varying costs. More tubes may increase material costs significantly.

Conclusion

The tube count in a heat exchanger is a critical design element that directly affects its performance, efficiency, and overall operational costs. By increasing the number of tubes, engineers can enhance heat transfer efficiency but must also consider the increased pressure drop and potential changes in fluid velocity. Achieving the right tube count necessitates a comprehensive understanding of the application requirements, spatial constraints, and economic considerations.

In conclusion, the design of heat exchangers, particularly concerning tube count, requires a careful evaluation of various factors to optimize performance while managing costs and ensuring efficient operation. Whether it’s in power generation, industrial processing, or other applications, the importance of tube count cannot be overstated—it is a vital component in ensuring energy efficiency and effective thermal management in countless systems around the world.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025