okt . 02, 2024 23:38 Back to list

Top Manufacturers of Stainless Steel Parts for Various Industries

Understanding Parts Stainless Steel Manufacturers Quality and Innovation in Metal Fabrication

In today's rapidly evolving industrial landscape, stainless steel plays a pivotal role in various applications due to its remarkable properties, including corrosion resistance, durability, and aesthetic appeal. As industries such as automotive, aerospace, healthcare, and construction continue to expand, manufacturers specializing in stainless steel parts have emerged as critical players in meeting the high demand for quality components. This article delves into the significance of stainless steel manufacturers, the processes they employ, and the innovative solutions they bring to different sectors.

The Importance of Stainless Steel Parts

Stainless steel is an alloy primarily composed of iron, chromium, and nickel, which gives it unique characteristics that differentiate it from regular steel. Its ability to resist corrosion and withstand high temperatures makes it an ideal choice for various applications, from kitchen appliances and cutlery to complex machinery parts and structural components in buildings. The demand for stainless steel parts is not only driven by their functional advantages but also by their contribution to sustainability. Stainless steel is 100% recyclable, making it an environmentally friendly option in today's market.

Key Manufacturers in the Industry

When it comes to sourcing stainless steel parts, manufacturers play a crucial role. They are responsible for producing components that meet stringent standards of quality, safety, and performance. Various companies specialize in fabricating stainless steel parts, often working on custom orders tailored to specific client needs. Some key players in the stainless steel manufacturing sector include large conglomerates and specialized fabricators. These manufacturers differ in terms of their capabilities, including machining, welding, and finishing processes, yet all share a commitment to delivering high-quality products.

Manufacturing Processes

The production of stainless steel parts involves numerous processes that ensure the final product meets industry specifications. Here are some common methods employed by stainless steel manufacturers

1. CNC Machining Computer Numerical Control (CNC) machining is a highly precise process that allows manufacturers to create intricate designs from stainless steel sheets or blocks. This technology ensures consistent quality and repeatability, which is essential for mass production.

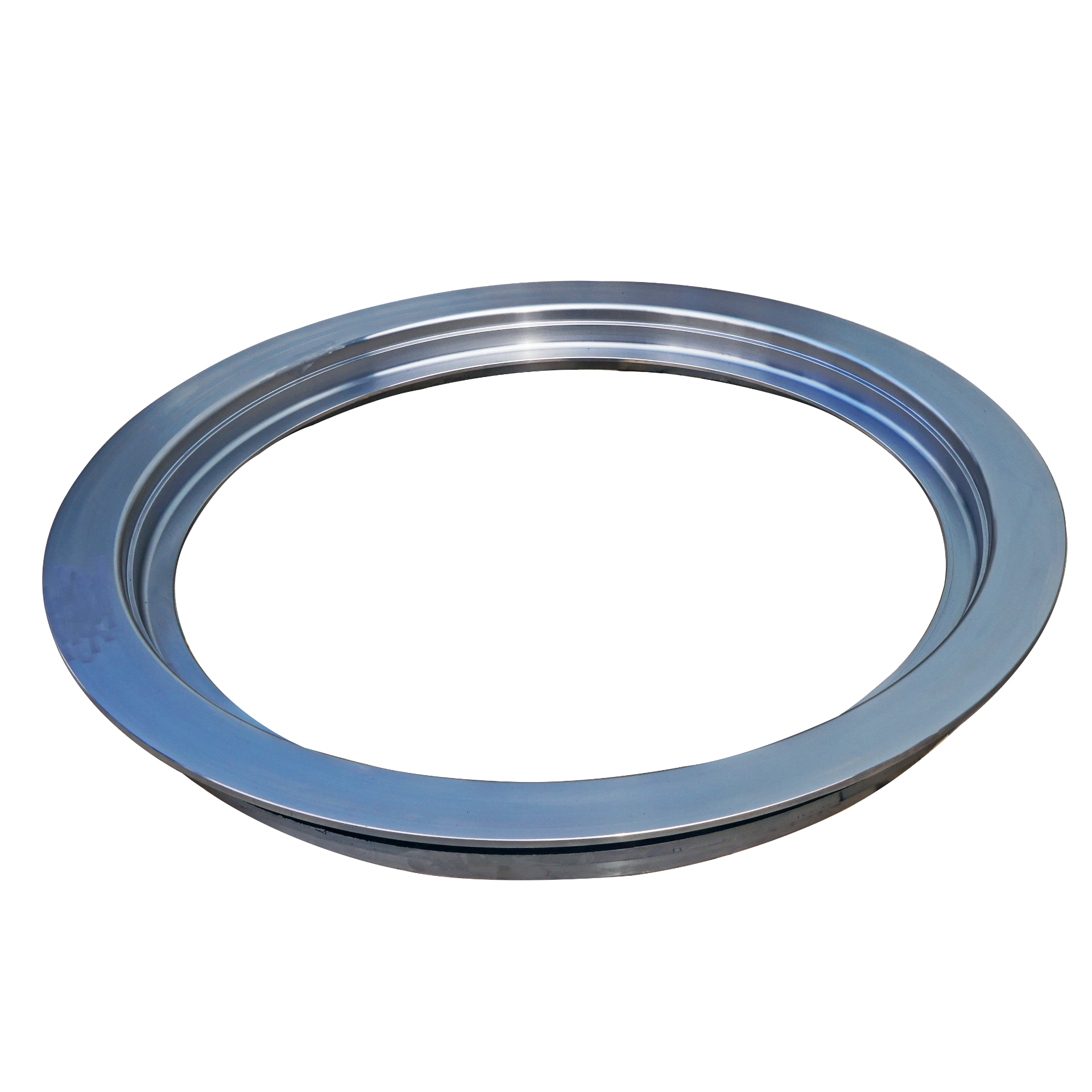

parts stainless steel manufacturers

2. Metal Stamping This process involves the use of dies to cut or shape stainless steel into desired forms. It is particularly useful for producing high volumes of parts quickly, making it suitable for industries like automotive manufacturing.

3. Welding Stainless steel welding is critical in the assembly of various components. Techniques such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding ensure strong and durable joints, essential for structural integrity in machinery and equipment.

4. Finishing Techniques After fabrication, stainless steel parts often undergo finishing processes such as polishing, passivation, and coating. These techniques enhance the material's appearance, improve corrosion resistance, and prolong its lifespan.

Innovation in Stainless Steel Parts Manufacturing

As industries evolve, so do the manufacturing techniques and technologies used to create stainless steel components. Manufacturers are increasingly adopting advanced technologies such as additive manufacturing (3D printing) and automation. These innovations offer numerous advantages, including reduced waste, increased design flexibility, and shortened lead times. By leveraging these technologies, manufacturers can produce complex geometries that were previously unattainable with traditional methods.

Furthermore, the emphasis on sustainability is leading to the development of eco-friendly production processes and materials. Manufacturers are investigating ways to reduce their carbon footprint, optimize resource usage, and enhance recyclability, aligning their operations with global sustainability goals.

Conclusion

The role of parts stainless steel manufacturers is integral to the modern industrial ecosystem. With their ability to combine advanced manufacturing processes with high-quality materials, these manufacturers provide components that are essential in a wide range of applications. Their commitment to innovation and sustainability positions them as leaders in the field, ensuring that industries can continue to rely on stainless steel for its unmatched performance. As demand continues to rise, the future of stainless steel manufacturing promises exciting developments that will further enhance the capabilities and applications of this versatile material. Whether for industrial, structural, or consumer applications, stainless steel parts remain a cornerstone of modern manufacturing.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025