Oct . 10, 2024 07:03 Back to list

worm gear and wheel manufacturing plant for precision engineering solutions

Worm Gear and Wheel Factory Precision Engineering for Modern Machinery

In the realm of mechanical engineering, the worm gear and wheel system stands out as a pivotal component in various machinery applications. At the heart of this intricate mechanism lies the worm gear and wheel factory, a facility dedicated to producing these essential components with unparalleled precision and quality. This article explores the significance of worm gears and wheels, the manufacturing process involved in their production, and the innovations shaping the future of this industry.

Worm gears are characterized by their unique design, which consists of a screw-like worm that meshes with a toothed wheel. This configuration allows for high torque transmission and a significant reduction in speed. One of the defining features of worm gears is their ability to provide a mechanical advantage while minimizing backlash. As a result, they show excellence in applications requiring precise positioning, such as in conveyor systems, elevators, and various robotics applications.

The production of worm gears and wheels takes place in specialized factories equipped with advanced machinery and technology. The process typically begins with the selection of high-quality materials, such as hardened steel or bronze, which are crucial for durability and reliability. The first step in manufacturing involves forging or machining the worm and wheel components, where cutting-edge CNC machines ensure the accurate dimensions and geometrical precision required for optimal performance.

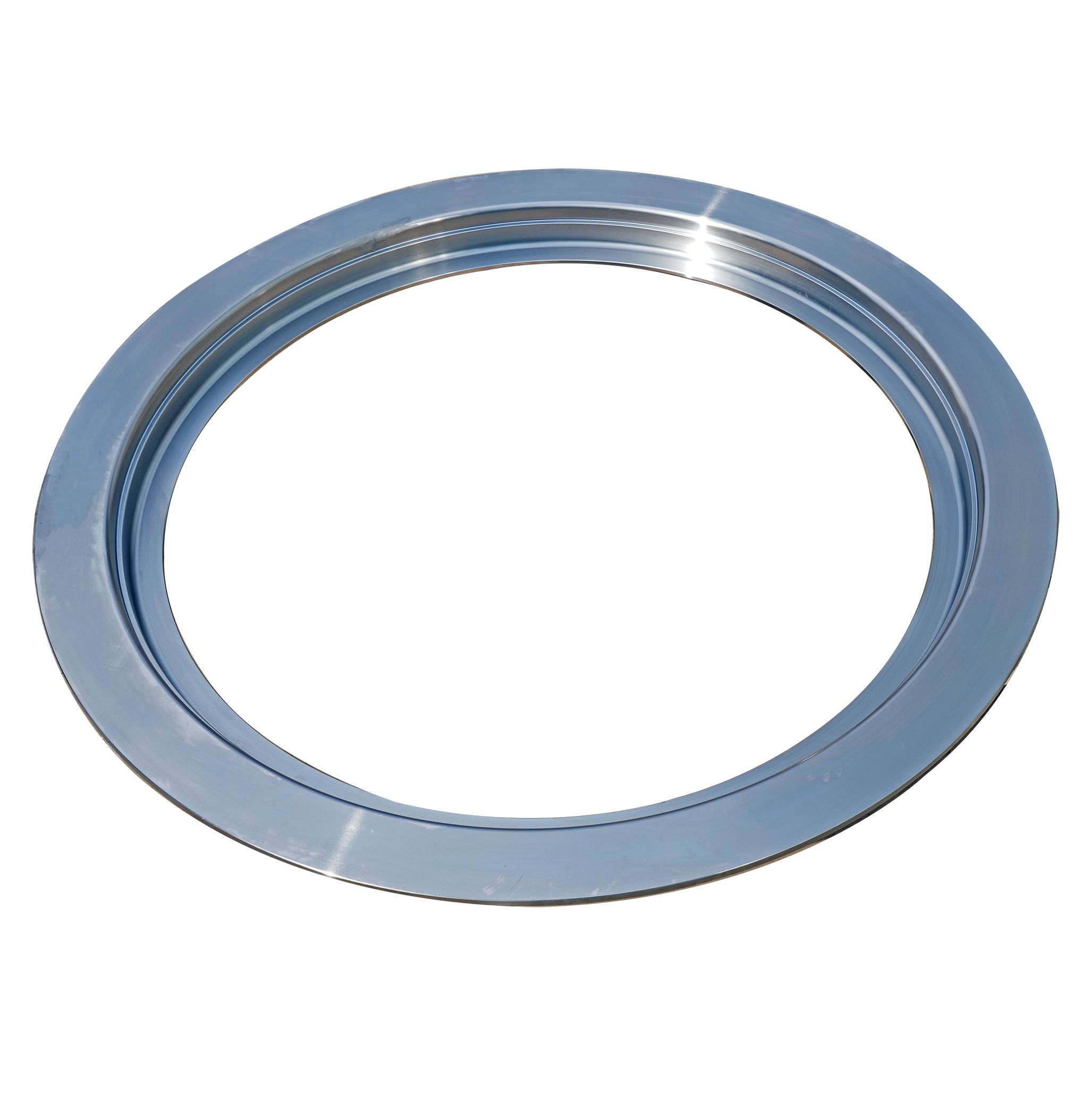

worm gear and wheel factory

Following the machining phase, the components undergo a rigorous heat treatment process to enhance their hardness and wear resistance. This is particularly important for worm gears, as they endure significant stress during operation. After heat treatment, the gears are carefully inspected using various quality assurance techniques, including using coordinate measuring machines (CMM) and advanced surface finish analyzers, to ensure they meet the strict tolerance levels demanded by industry standards.

Once the components pass quality checks, they are assembled into complete worm gear and wheel systems. This assembly process requires meticulous attention to detail, as improper alignment can lead to decreased efficiency and increased wear. Modern factories often utilize automated assembly lines to enhance precision and speed, reducing human error and increasing overall productivity.

As industries continue to evolve, so too does the technology behind worm gears and wheels. The integration of smart manufacturing practices, such as IoT sensors and data analytics, is transforming traditional operations. These innovations facilitate predictive maintenance, ensuring that machinery operates seamlessly while maximizing uptime.

In conclusion, the worm gear and wheel factory plays a crucial role in the mechanical engineering landscape. By focusing on precision manufacturing, rigorous quality control, and embracing technological advancements, these factories contribute significantly to the reliability and efficiency of modern machinery. As industries increasingly demand high-performance components, the importance of worm gears and wheels will continue to grow, driving further innovations in their production and applications.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025