Nov . 01, 2024 09:20 Back to list

Custom Manufacturing of Stamped Concrete Pipe Mold Bottom Rings for Quality Production

The Importance of Stamped Concrete Pipe Mold Bottom Rings in Construction

In the realm of modern construction, the use of quality materials and manufacturing techniques is paramount. One essential component often overlooked is the bottom ring of concrete pipe molds, particularly those that utilize stamped designs. This article will explore the significance of these components in the manufacturing process and their broader impact on construction projects.

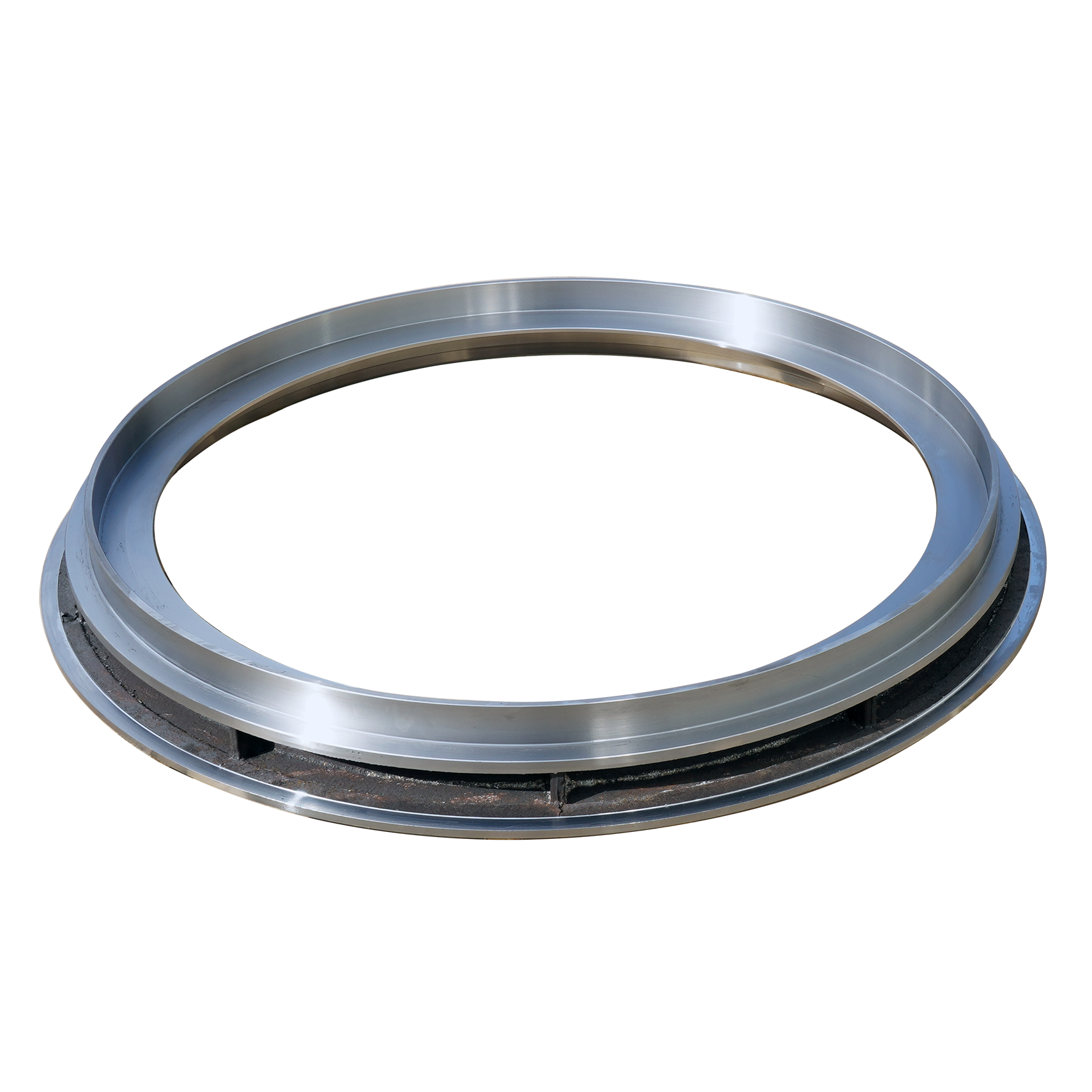

Concrete pipe molds serve a vital role in creating durable and reliable structures used in various applications, including drainage systems, sewage management, and stormwater control. The bottom ring of these molds is crucial because it establishes the foundational shape and stability of the concrete pipe during the pouring and curing processes. Traditional methods of mold manufacturing often overlook the aesthetic and functional possibilities of incorporating stamped patterns into the design.

The stamped concrete pipe mold bottom rings begin with high-quality materials that can withstand the rigors of repeated use. Factories specializing in the production of these molds employ advanced techniques to ensure precision and durability. The stamping process allows for intricate designs to be imprinted onto the mold, which can add not only aesthetic value but also functional benefits. For instance, a stamped texture can enhance bonding with the concrete, leading to stronger pipe formations.

stamp concrete pipe mold bottom ring factory

Moreover, the use of stamped designs is an innovative approach that can greatly influence the logistical aspects of a construction project. By incorporating various motifs or surface textures into the mold's design, manufacturers can provide clients with a product tailored to specific requirements. This customization can ensure that the final concrete pipes seamlessly integrate into their intended environments, whether for municipal use or architectural applications.

Another crucial aspect of the stamped concrete pipe mold bottom rings is their contribution to maximizing efficiency in manufacturing processes. Standardized molds reduce production time and labor costs, which is particularly beneficial in large-scale construction projects where time is often of the essence. The reliability and repeatability of these molds ensure that the finished products meet stringent quality requirements, thereby reducing the likelihood of costly delays due to material failures.

Furthermore, sustainability is an increasing concern in the construction industry. The robust nature of stamped concrete molds means they can be reused multiple times, significantly cutting down on waste and minimizing the environmental footprint of construction activities. As industries shift towards more eco-friendly practices, being able to utilize durable molds aligns with global efforts to promote sustainability.

In conclusion, the stamped concrete pipe mold bottom rings represent an essential innovation in manufacturing practices within the construction industry. Their combination of aesthetic appeal, structural integrity, and cost-effectiveness makes them invaluable to builders and engineers alike. As construction projects continue to evolve, embracing advanced manufacturing techniques like stamped mold designs will not only enhance the quality of infrastructure but also promote more sustainable practices for the future. The future of construction is undoubtedly intertwined with innovations like these, and their importance will only grow as the industry seeks new ways to balance functionality with environmental consciousness.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025