ਨਵੰ. . 25, 2024 06:57 Back to list

Foundry for Manufacturing High-Quality Cast Iron Components and Parts

The Importance of Cast Iron Parts in Modern Manufacturing

In the world of manufacturing, cast iron parts play a crucial role across various industries. With its unique properties and versatility, cast iron has become a preferred material for creating a wide range of components. From automotive parts to machinery, the production of cast iron components is a central aspect of many factories today.

Cast iron is an alloy composed primarily of iron, carbon, and silicon. Its high carbon content gives it excellent fluidity when molten, allowing it to easily fill molds during the casting process. This fluidity, combined with its excellent wear resistance and ability to withstand high temperatures, makes cast iron an ideal material for producing durable parts. Furthermore, cast iron parts can be machined, welded, and heat-treated, adding to their appeal in various manufacturing applications.

The Importance of Cast Iron Parts in Modern Manufacturing

Another significant aspect of cast iron production is its cost-effectiveness. The raw materials used to produce cast iron are relatively abundant and inexpensive, allowing factories to maintain lower production costs. Additionally, the casting process used to create these parts is efficient, enabling high-volume production. This efficiency means that manufacturers can meet demand without significant delays, which is vital in today’s fast-paced industrial environment.

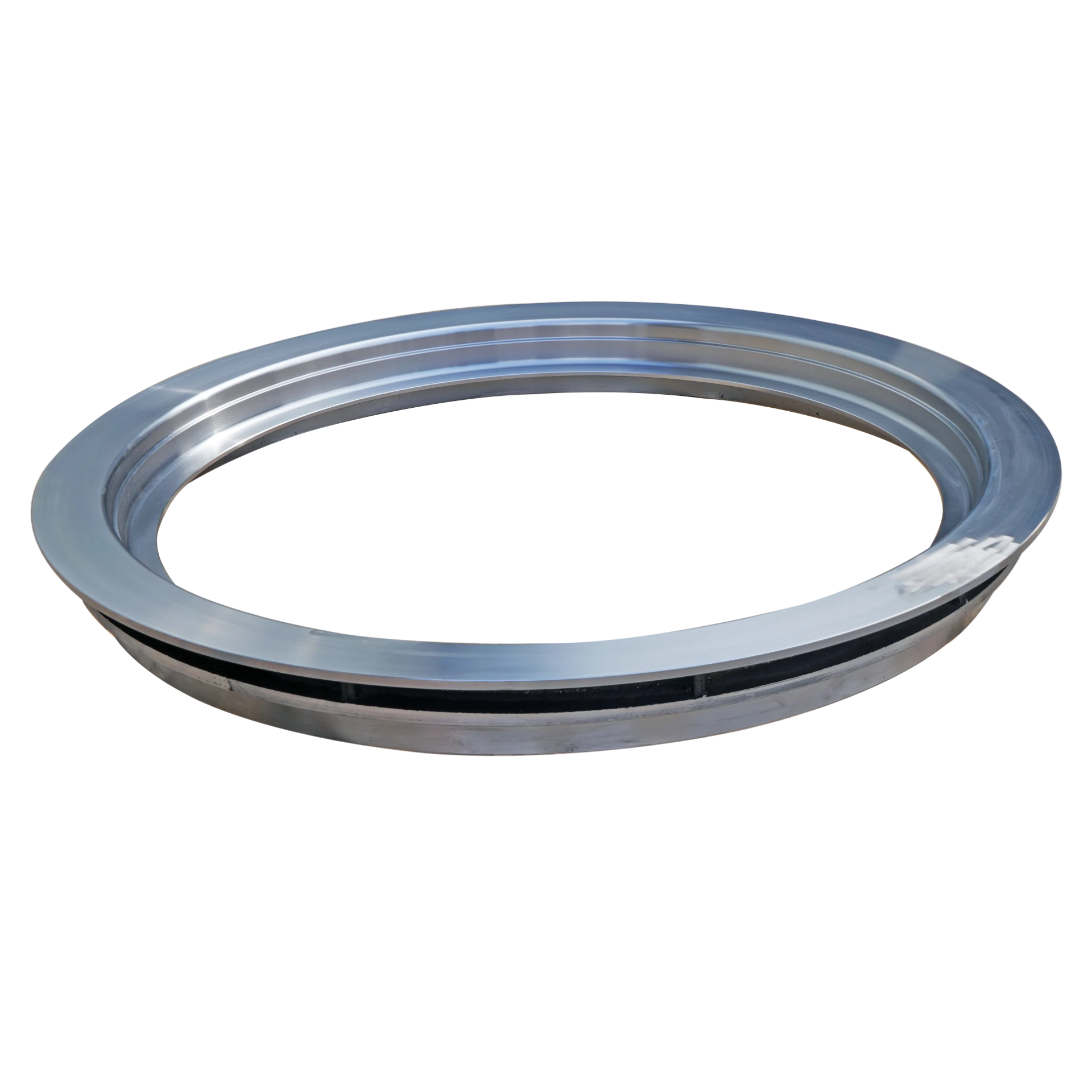

cast iron parts factory

Furthermore, the versatility of cast iron allows for its application in various domains. For instance, in the automotive industry, cast iron is commonly used for engine blocks, cylinder heads, and brake components. Its strength and durability ensure that these critical parts can withstand the rigors of daily use. Similarly, in the construction industry, cast iron is utilized for pipes, fittings, and structural components due to its resilience and resistance to corrosion.

Quality control is paramount in the production of cast iron parts. Modern factories employ advanced techniques and technologies to ensure that every piece meets stringent specifications. This includes precise temperature control during the melting and casting processes, as well as rigorous inspection protocols. By maintaining high standards, manufacturers can produce reliable parts that meet the needs of their clients and comply with industry regulations.

Additionally, environmental considerations are becoming increasingly important in the manufacturing process. Many cast iron parts factories are adopting more sustainable practices, such as recycling scrap metal and utilizing energy-efficient technologies. This not only minimizes waste but also reduces the carbon footprint associated with production, aligning with the global push towards more environmentally responsible manufacturing.

In conclusion, cast iron parts are indispensable in modern manufacturing, providing durability, cost-effectiveness, and versatility across various industries. As factories continue to innovate and improve their production techniques, the demand for high-quality cast iron components will only grow. By prioritizing quality control and sustainable practices, cast iron parts manufacturers can ensure their relevance in an ever-evolving market, solidifying the material’s place in the future of manufacturing. Whether in automotive applications, machinery, or construction, cast iron remains a fundamental building block in the landscape of industrial production.

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025