ਜੂਨ . 08, 2025 04:13 Back to list

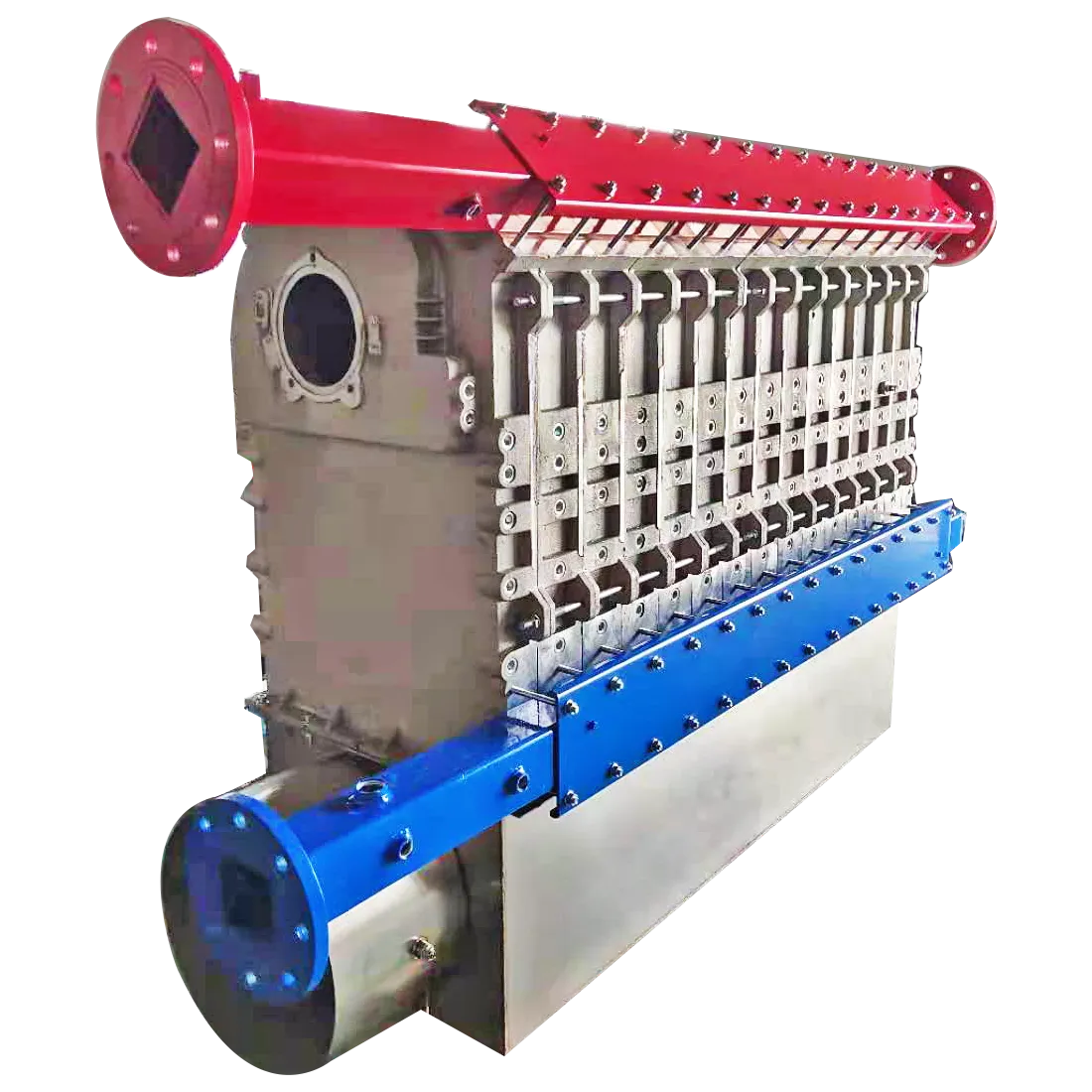

Custom Low Nitrogen Domestic Hot Water Condensing Gas Boiler

- Introduction to modern gas boilers for domestic heating systems

- Cutting-edge technological advantages explained

- Environmental impact statistics and efficiency data

- Leading manufacturer comparison tables

- Custom engineering solutions for specific requirements

- Real-world implementation case studies

- Guidance for purchasing high-efficiency boilers

(domestic hot water gas boiler)

Modern Home Heating with Efficient Domestic Hot Water Gas Boilers

Heating solutions have evolved significantly, with domestic hot water gas boiler

s now serving as the cornerstone of residential comfort systems globally. These advanced appliances provide consistent on-demand hot water while dramatically reducing energy expenditures compared to traditional models. Contemporary units utilize precision engineering to extract maximum thermal value from fuel sources while maintaining compact footprints suitable for urban installations.

Technological Superiority in Heating Systems

Low nitrogen condensing models deliver unprecedented efficiency levels through dual-stage heat exchange mechanisms. Primary combustion chambers generate initial heat while secondary condensing systems capture latent energy from exhaust gases, achieving thermal efficiencies exceeding 97%. Advanced modulation controls automatically adjust flame intensity from 20% to 100% capacity, matching output precisely to demand. Stainless steel heat exchangers resist corrosion while copper-silicon alloy water pathways ensure longevity under hard water conditions.

Integrated self-diagnostic systems monitor performance parameters including water pressure, gas flow rates, and exhaust temperatures. Smart connectivity enables remote adjustment via mobile applications while tracking historical consumption patterns. Safety features include multi-layer freeze protection, automatic shutoff during irregular combustion, and carbon monoxide detection systems. These innovations collectively reduce maintenance requirements while extending equipment lifespan beyond 15 years.

Environmental and Economic Performance Data

Contemporary condensing gas boilers demonstrate measurable environmental benefits alongside cost reductions. Independent testing verifies emissions below 30mg/kWh of nitrogen oxides, representing 90% reductions compared to conventional models. Fuel utilization improvements yield 35% lower annual operating costs for average households, with documented savings exceeding $450 yearly in colder climates.

The following efficiency comparison demonstrates technological progress:

| Model Type | Thermal Efficiency | NOx Emissions (mg/kWh) | Annual Fuel Savings |

|---|---|---|---|

| Standard Gas Boiler | 78-84% | 120-180 | Baseline |

| Low Nitrogen Condensing Boiler | 94-98% | 24-35 | 32-38% |

| Premium Condensing with Modulating Burner | 97-99% | 18-28 | 41-46% |

Additionally, hydraulic innovations decrease circulation energy requirements by 40% through optimized flow designs. The economic return timeline ranges between 3-6 years across different regional utility rates, making these units financially viable replacements.

Comparative Analysis of Industry Leaders

Discerning buyers evaluate multiple manufacturers when selecting domestic hot water gas boiler equipment. Comprehensive testing reveals performance distinctions across brands:

| Manufacturer | Warranty Period | Modulation Ratio | NOx Certification Level | Sound Rating (dB) |

|---|---|---|---|---|

| PremierHeat ProLine | 12 years | 8:1 | EU Tier 5 | 42 |

| ThermoMax Elite Series | 10 years | 5:1 | EPA Tier 4 | 45 |

| EcoFlame Advanced | 15 years | 10:1 | California Air Compliant | 39 |

Performance gaps manifest primarily during partial-load conditions where modulation capabilities affect efficiency. PremierHeat and EcoFlame maintain efficiency above 92% even at minimum fire rates, while standard models often drop below 85%. Durability testing indicates premium stainless steel heat exchangers significantly outlast aluminum alternatives in hard water conditions.

Custom Engineering Solutions

Tailored domestic hot water gas boiler configurations address specific architectural constraints and usage requirements. Dual boiler installations provide redundancy for continuous operation during maintenance while maintaining efficiency through cascade control systems. Compact modular units enable installation in spatially restricted locations without compromising output capabilities through vertical flue configurations.

Customized low temperature designs serve radiant floor applications, operating consistently at 45-55°C flow temperatures. Hydronic buffer tanks permit zoning compatibility across structures exceeding 500m². For commercial installations requiring simultaneous heating and cooling, custom absorption chiller integrations enable combined operation efficiencies impossible with conventional equipment.

Implementation Success Studies

Multi-unit residential properties demonstrate practical results from system upgrades. A 72-unit apartment complex replaced conventional boilers with two custom domestic hot water low nitrogen condensing gas fired boilers operating in cascade. The installation recorded 42% annual gas consumption reductions while maintaining consistent water temperatures. Monitoring showed particulate emissions below detectable levels, eliminating chimney cleaning expenses.

Historic building renovations present unique heating challenges addressed by specialized configurations. A landmark hotel integrated custom domestic hot water gas boiler units within existing chimney structures, preserving architectural integrity while achieving 97% seasonal efficiency. Low temperature return operation prevented condensation damage to vintage masonry. Maintenance logs indicate zero failures across five heating seasons.

Acquiring Advanced Domestic Hot Water Gas Boilers

Identifying proper sizing constitutes the fundamental purchasing consideration for domestic hot water gas boiler systems. Load calculations must account for building envelope characteristics, regional climate conditions, and occupancy patterns. Professional assessments typically reveal oversized installations by 30-50% in existing structures, reducing efficiency through excessive cycling. Buy domestic hot water low nitrogen condensing gas fired boiler units directly through certified distributors to guarantee authentic components and factory-direct support channels.

Installation certification programs guarantee adherence to manufacturer specifications for venting and combustion air supply. Rebate verification tools maximize financial returns by identifying federal, state, and utility incentive programs that typically offset 15-30% of capital expenditures. Extended warranties provide additional security when covering both parts and labor components for comprehensive system protection beyond standard coverage limitations.

(domestic hot water gas boiler)

FAQS on domestic hot water gas boiler

Customization Options for Low Nitrogen Boilers

Q: What aspects can be customized in a domestic hot water low nitrogen condensing gas boiler?

A: Our custom solutions adapt boiler capacity, fuel pressure specifications, and physical dimensions for precise installation fits. Low-NOx burner configurations and smart control interfaces are tailored to local emission regulations and user preferences. We prioritize thermal efficiency optimization during bespoke engineering.

Buying Criteria for Low Nitrogen Condensing Boilers

Q: What factors should I consider when purchasing a domestic hot water low nitrogen condensing gas boiler?

A: Evaluate annual fuel utilization efficiency (AFUE) ratings above 90% to ensure energy savings and lower operating costs. Verify third-party certifications like NSF/ANSI for NOx emissions compliance. Confirm integrated condensing heat exchanger warranties against corrosion to protect your investment.

Installation Requirements for Custom Boilers

Q: Are there special installation considerations for custom domestic hot water gas boilers?

A: Space constraints, gas line pressure requirements, and exhaust venting systems must be pre-assessed for optimal positioning. Condensate drain provisions are critical for low nitrogen units to handle acidic byproducts. Professional HVAC technicians should verify combustion air supply adequacy post-installation.

Operational Advantages of Condensing Boilers

Q: How does a condensing gas boiler improve domestic hot water performance?

A: Secondary heat exchangers recover latent energy from flue gases, increasing efficiency by 10-15% over conventional models. Precise modulating burners adjust flame size proportionally to demand, maintaining consistent temperatures. This dual-stage operation cuts gas consumption while lowering nitrogen oxide emissions below 20ppm.

Technical Support for Customized Units

Q: What technical assistance comes with custom domestic hot water boiler orders?

A: We provide digital twin simulations to visualize performance before manufacturing. Installation schematics include BOM-specific component diagrams and wiring layouts. Lifetime remote diagnostics via IoT interfaces enable real-time efficiency monitoring and predictive maintenance alerts.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025