ਜਨਃ . 01, 2025 08:44 Back to list

Top Investment Casting Suppliers for Your Precision Manufacturing Needs

Understanding the Role of Investment Casting Suppliers

Investment casting, often referred to as lost-wax casting, is a highly versatile manufacturing process used to create intricate metal parts with excellent dimensional accuracy. This method is employed in various industries, including aerospace, automotive, medical, and general engineering. At the heart of this process lies the investment casting supplier, a crucial player that provides the necessary expertise, materials, and technology to ensure the production of high-quality castings.

What is Investment Casting?

The investment casting process involves creating a wax pattern, which is then coated in a ceramic shell. Once the shell hardens, the wax is melted away, leaving a detailed mold ready for metal pouring. The advantages of investment casting include the ability to produce complex shapes, excellent surface finish, and precise tolerances, making it ideal for both small and large-scale production runs.

The Role of Investment Casting Suppliers

Investment casting suppliers provide the foundational elements necessary for successful casting processes. Their role can be broken down into several key areas

1. Material Provision Investment casting suppliers are responsible for supplying high-quality metal alloys tailored to specific applications. Common materials include aluminum, steel, bronze, and superalloys, each selected based on the desired properties of the final product, such as strength, corrosion resistance, and weight.

investment casting supplier

2. Technical Expertise A reputable supplier offers technical support and expertise in the investment casting process. This includes advice on design optimization, tooling, and process parameters to ensure that the final product meets required specifications. Many suppliers also invest in research and development to advance casting techniques and improve material properties.

3. Quality Assurance Suppliers are often responsible for implementing stringent quality control measures throughout the casting process. This includes conducting material inspections, in-process checks, and final product evaluations to ensure that every casting meets industry standards and customer expectations. Certification to international quality standards, such as ISO 9001, is common among investment casting suppliers.

4. Custom Solutions Each project presents unique challenges and requirements. Investment casting suppliers often work closely with their clients to understand specific needs and develop customized solutions. This collaboration can significantly enhance the efficiency and quality of the resulting castings.

5. Production Capabilities Investment casting suppliers can vary widely in terms of their production capabilities. Some specialize in low-volume, high-precision parts, while others may focus on high-volume production. Understanding the specific capabilities of a supplier is essential when assessing their suitability for a particular project.

6. Sustainability Practices As industries strive for sustainability, many investment casting suppliers are adapting their practices. They may implement recycling programs to reclaim materials, use eco-friendly coatings, and invest in energy-efficient operations. Choosing a supplier committed to sustainable practices can help companies meet their environmental goals.

Conclusion

Investment casting suppliers play an essential role in the manufacturing landscape by providing the necessary materials, expertise, and quality assurance needed to produce intricate metal components. By partnering with the right supplier, businesses can enhance their production processes, ensure product quality, and ultimately deliver superior products to their customers. As industries continue to evolve, the contributions of investment casting suppliers will remain vital, fostering innovation and efficiency in the manufacturing sector. Thus, understanding the intricacies of investment casting and the capabilities of suppliers is crucial for any organization looking to leverage this advanced technology.

-

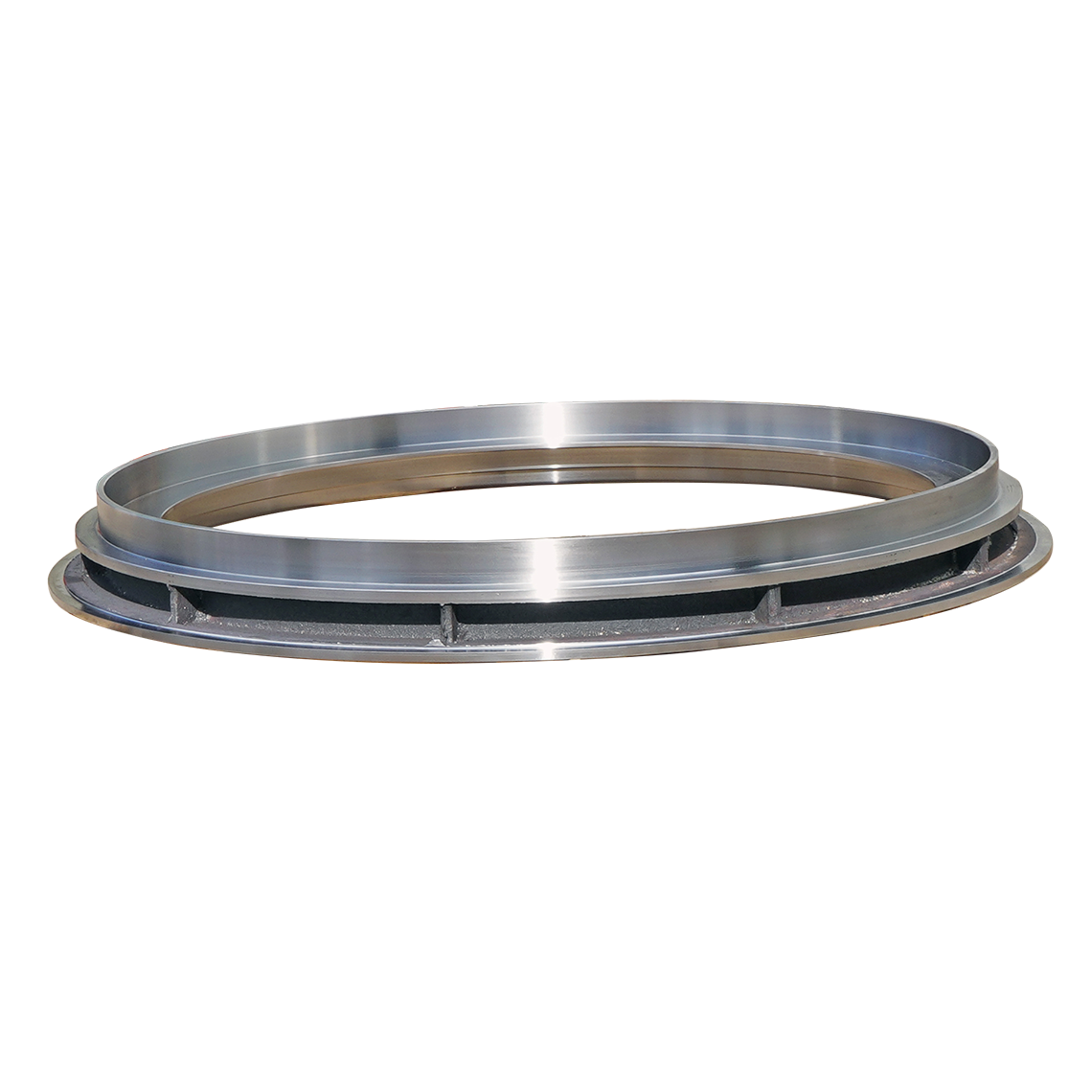

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025