lis . 30, 2024 00:14 Back to list

steel casting manufacturers

Exploring the World of Steel Casting Manufacturers

Steel casting is a crucial process in the manufacturing industry, playing a vital role in producing components for a wide range of applications. From automotive parts to heavy machinery, the versatility and strength of steel make it a preferred material for many manufacturers. In this article, we will explore what steel casting is, the importance of steel casting manufacturers, their processes, challenges they face, and the future of the industry.

What is Steel Casting?

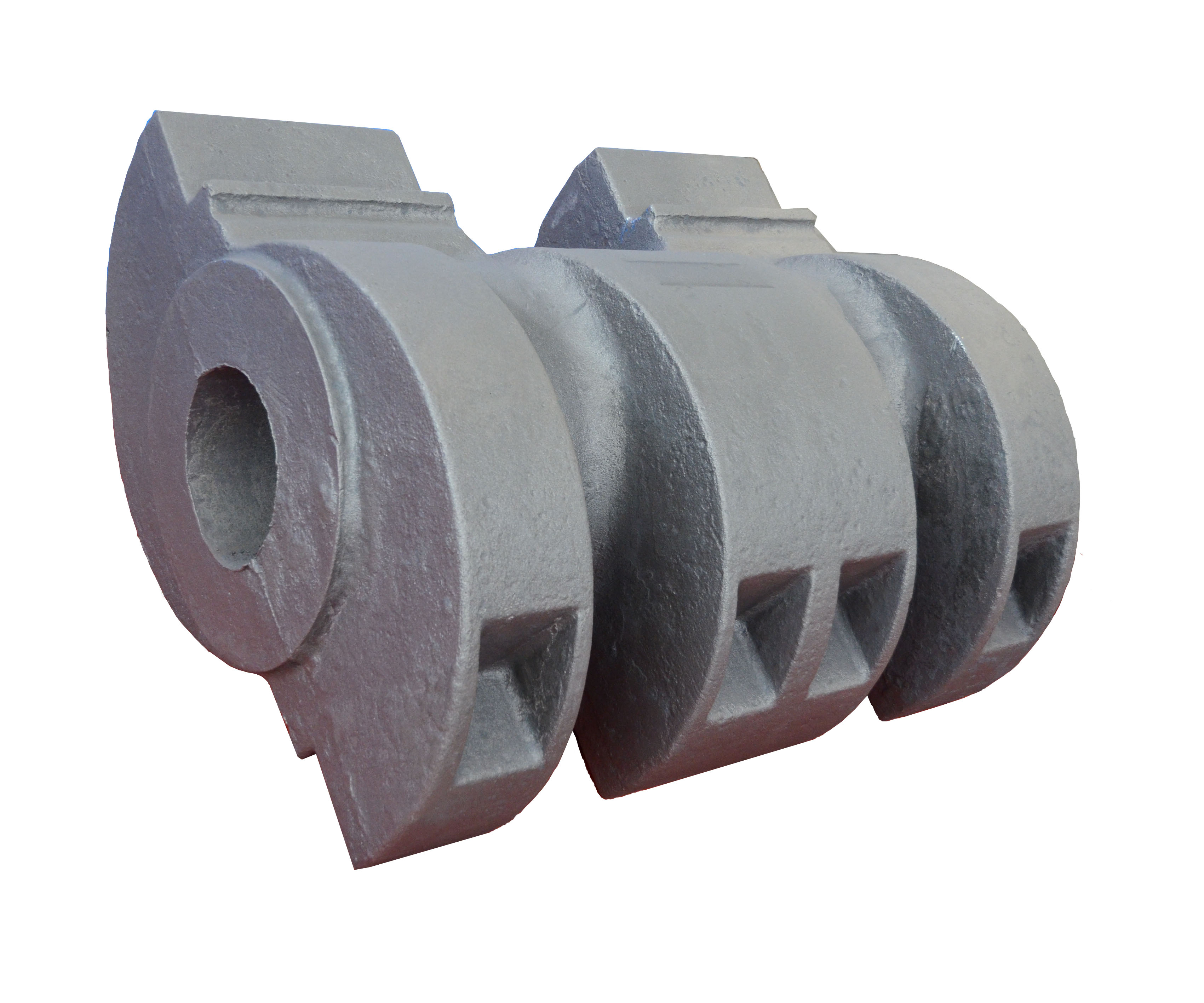

Steel casting is the process of pouring molten steel into a mold to create a specific shape or component. This method allows for the production of intricate designs that may be difficult or impossible to achieve with other manufacturing techniques, such as forging or machining. The cast parts have exceptional mechanical properties, including high strength, ductility, and resistance to wear and corrosion, making them ideal for various industries.

The Role of Steel Casting Manufacturers

Steel casting manufacturers are companies that specialize in the production of cast steel components. They service a myriad of sectors, including construction, aerospace, automotive, oil and gas, and general engineering. The importance of these manufacturers cannot be overstated, as they are essential for the supply chain of numerous industries. Without them, many machines and structures would lack pivotal components, hindering production and development worldwide.

These manufacturers invest heavily in technology and skilled labor to ensure that they can produce high-quality castings that meet stringent industry standards. Their expertise in metallurgy, design, and processing techniques plays a significant role in the performance and reliability of the final products.

The Steel Casting Process

The steel casting process generally consists of several key steps

steel casting manufacturers

1. Pattern Making A pattern of the desired part is created, which can be made from various materials, such as wood or metal. 2. Mold Making The pattern is used to create a mold, typically made of sand or metal, which will form the exterior of the cast once the steel is poured in. 3. Melting Steel scrap or ingots are melted in a furnace to achieve the desired chemical composition and temperature. 4. Pouring The molten steel is poured into the mold, where it will cool and solidify to form the casting. 5. Finishing Once solidified, the casting is removed from the mold and undergoes a series of finishing processes, such as machining, heat treating, and surface treatment, to meet the required specifications.

Challenges Faced by Steel Casting Manufacturers

Despite the vital role they play, steel casting manufacturers face several challenges. The fluctuating prices of raw materials can impact profitability, while increasing labor costs and the need for skilled workers can strain operations. Moreover, manufacturers must continually adapt to technological advancements and environmental regulations. As industries push for more sustainable practices, steel casting producers are under pressure to reduce emissions and waste.

The Future of the Steel Casting Industry

Looking ahead, the steel casting industry is poised for significant change and growth. Advances in technology, such as additive manufacturing and automation, are revolutionizing traditional casting processes. Digital tools enable manufacturers to simulate the casting process, improving accuracy and reducing defect rates. Moreover, as electric vehicles and renewable energy technologies gain traction, new opportunities for steel casting manufacturers to innovate and expand their product offerings arise.

Furthermore, the industry's focus on sustainability will drive the development of eco-friendly practices, including recycling scrap materials and developing energy-efficient production methods. Manufacturers that embrace these trends will be better positioned to succeed in the evolving market landscape.

Conclusion

Steel casting manufacturers serve as the backbone of various industries by providing essential components that facilitate modern life and industry. As technology continues to advance and sustainability becomes a priority, these manufacturers will need to adapt and innovate. Their ability to meet challenges head-on will determine not only their success but also the overall progress of industries relying on their products. Thus, the future of steel casting manufacturing looks promising, filled with opportunities for growth and development.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025