Feb . 11, 2025 22:02 Back to list

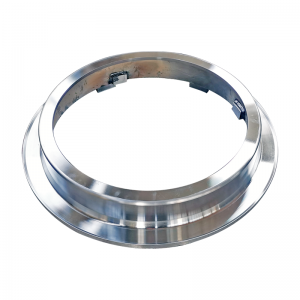

heat exchanger on ship

In maritime operations, the significance of a heat exchanger on ships cannot be overstated. This pivotal component plays an essential role in maintaining the overall functionality of the vessel’s machinery, particularly the engine components, which require vigorous temperature regulation. As an expert in marine engineering, with years of experience dealing with shipboard systems, I can attest to the transformative impact that well-designed heat exchangers have on the efficiency and reliability of maritime vessels.

Installation and maintenance expertise also play significant roles in the effectiveness of heat exchangers. Incorrect installation can lead to issues such as fluid leaks or operational inefficiencies. Regular maintenance is necessary to prevent fouling, a common problem where deposits accumulate on heat exchanger surfaces, impairing efficiency. Strategies such as regular cleaning and the use of anti-fouling coatings can mitigate these challenges. Recent advancements in heat exchanger technology have further enhanced their efficiency and reliability. For instance, the integration of advanced computer simulations in design has allowed for the optimization of fluid dynamics and heat transfer pathways. Additionally, innovations in materials science offer new alloys that provide improved corrosion resistance and thermal conductivity, extending the lifespan of these critical components. Given the essential function of heat exchangers in maintaining shipboard operations, authority in handling and advising on these systems is crucial. A crew trained in the specific operations and troubleshooting of heat exchangers can prevent minor issues from escalating into larger failures. Furthermore, professionals in the marine industry must always be updated with the latest developments to implement the most efficient strategies and technologies. In conclusion, the heat exchanger is a cornerstone of naval architecture, integral for vessel efficacy and safety. Thorough understanding, expert maintenance, and continual technological advancements in heat exchanger systems directly contribute to sustainable maritime operations. As a trusted authority within the marine engineering sector, my experiences and knowledge advocate for the continuous evolution of heat exchanger technology, underlining its importance in the smooth operation of maritime vessels.

Installation and maintenance expertise also play significant roles in the effectiveness of heat exchangers. Incorrect installation can lead to issues such as fluid leaks or operational inefficiencies. Regular maintenance is necessary to prevent fouling, a common problem where deposits accumulate on heat exchanger surfaces, impairing efficiency. Strategies such as regular cleaning and the use of anti-fouling coatings can mitigate these challenges. Recent advancements in heat exchanger technology have further enhanced their efficiency and reliability. For instance, the integration of advanced computer simulations in design has allowed for the optimization of fluid dynamics and heat transfer pathways. Additionally, innovations in materials science offer new alloys that provide improved corrosion resistance and thermal conductivity, extending the lifespan of these critical components. Given the essential function of heat exchangers in maintaining shipboard operations, authority in handling and advising on these systems is crucial. A crew trained in the specific operations and troubleshooting of heat exchangers can prevent minor issues from escalating into larger failures. Furthermore, professionals in the marine industry must always be updated with the latest developments to implement the most efficient strategies and technologies. In conclusion, the heat exchanger is a cornerstone of naval architecture, integral for vessel efficacy and safety. Thorough understanding, expert maintenance, and continual technological advancements in heat exchanger systems directly contribute to sustainable maritime operations. As a trusted authority within the marine engineering sector, my experiences and knowledge advocate for the continuous evolution of heat exchanger technology, underlining its importance in the smooth operation of maritime vessels.

Share

Pervious:

Next:

Latest news

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025