Nov . 04, 2024 15:39 Back to list

silica sol casting factory

The Importance of Silica Sol Casting in Modern Manufacturing

In the ever-evolving world of manufacturing, the methods and materials used have a profound impact on product quality, efficiency, and sustainability. One such method that has gained significant traction in recent years is silica sol casting, a precision casting technique that offers numerous advantages over traditional methods. Silica sol casting factories are at the forefront of this technology, pushing the boundaries of what is possible in various industries.

The Importance of Silica Sol Casting in Modern Manufacturing

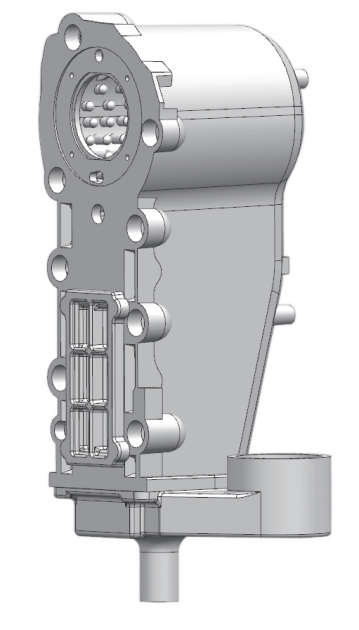

One of the standout benefits of silica sol casting is its ability to produce complex geometries with excellent detail. This is crucial in industries where components must fit together seamlessly, as even the slightest deviation can lead to catastrophic failures. For example, in aerospace applications, the performance of an aircraft engine heavily relies on the precision of its cast components. By employing silica sol casting, manufacturers can significantly reduce the risk of defects and enhance the overall reliability of their products.

silica sol casting factory

Furthermore, silica sol casting is an environmentally friendly option compared to traditional casting methods. The process generates less waste and utilizes water-based binders, reducing the reliance on harmful chemicals. Many silica sol casting factories are committed to sustainable practices, pushing for greater efficiency and minimizing their carbon footprint. This adherence to environmental standards not only benefits the planet but also aligns with consumer demand for greener technologies.

Cost-effectiveness is another compelling reason why silica sol casting is gaining popularity. Although the initial setup costs might be higher due to the specialized equipment and materials required, the long-term savings are substantial. The reduced need for machining due to improved surface finishes and dimensional accuracy means lower labor costs and less material waste. As manufacturers continue to seek ways to optimize production processes, silica sol casting stands out as a viable and economical solution.

In conclusion, silica sol casting represents a significant advancement in the field of manufacturing. With its ability to produce intricate designs, improve product quality, and adhere to environmental standards, silica sol casting factories are reshaping the future of production across various sectors. As industries strive for innovation and efficiency, the adoption of silica sol technology is likely to increase, offering a promising path forward for manufacturers looking to stay competitive in a rapidly changing market. The evolution of casting methods emphasizes the need for continuous development and adaptation in order to meet the demands of modern engineering and consumer needs.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025