Jun . 03, 2025 19:55 Back to list

China Steel Casting Foundry - Sand, Investment & Die Casting

- Global Foundry Market Statistics and Growth Projections

- Technical Advantages in Chinese Casting Production

- Comparative Analysis of Global Steel Casting Suppliers

- Custom Engineering Solutions for Industrial Applications

- Material Performance Across Different Casting Methods

- Automotive Sector Implementation Case Studies

- Certifications and Quality Assurance Protocols

(steel casting)

Steel Casting Market Outlook and Statistical Projections

Global demand for precision steel casting

services continues its upward trajectory with projected 5.2% CAGR growth through 2028, driven primarily by automotive and industrial machinery sectors. China currently accounts for 43% of worldwide steel casting production according to World Foundry Organization metrics, with coastal manufacturing regions like Zhejiang and Guangdong establishing specialized production clusters. Leading foundries have reduced defect rates from 8.2% to under 2.6% through automated molding systems and real-time metallurgical monitoring technology.

Export figures demonstrate China's dominance in grey iron and stainless steel casting exports, having shipped over $17.8 billion worth of precision cast components during 2022-2023 fiscal year. Investment casting facilities have particularly expanded capabilities for complex aerospace geometries achieving ±0.05mm dimensional consistency. Current development priorities focus on magnesium alloy alternatives for automotive light-weighting and integrated machining centers that reduce secondary operations by 70%.

Technological Leadership in Production Methodologies

Chinese foundries demonstrate exceptional technical sophistication through multi-process integration where resin sand casting provides surface finishes down to Ra 3.2μm for pump housings, while vacuum-assisted investment casting achieves near-net shapes for turbine blades. Proprietary V-process molding technology combines vacuum sealing with thermoforming for dimensional accuracy within 0.15% across large industrial valves and construction machinery components.

Advanced thermal analysis systems monitor molten metal chemistry in real-time, adjusting alloy composition during pouring for certified carbon steel grades. Computer simulations of solidification patterns have reduced rejection rates in pressure vessel castings from 5.3% to 1.2% within 36 months through gating system optimization. Robotic finishing cells perform consistent surface treatment across stainless steel food processing equipment requiring USDA-compliant finishes.

| Supplier Type | Typical Tolerance (±mm) | Minimum Wall Thickness | Batch Size Flexibility | Material Certification |

|---|---|---|---|---|

| Standard Chinese Foundries | 0.25 | 3.0mm | 100+ units | ISO 9001:2015 |

| Precision Casting Specialists | 0.10 | 1.5mm | 10 units | AS9100D, PED |

| Die Casting Providers | 0.15 | 1.0mm | 5,000+ units | IATF 16949 |

| Machining-Integrated Facilities | 0.05 | N/A (post-machined) | Prototype to mass | ISO 13485 |

Custom Manufacturing Solutions for Industrial Requirements

Leading stainless steel casting foundries now employ concurrent engineering models where design-for-manufacturing analysis begins during quotation phases. For centrifugal pump applications, hydrodynamic simulation informs optimized runner systems eliminating turbulence defects. Foundry technicians regularly process complex brass instrument components weighing under 50 grams alongside 18-ton carbon steel crusher jaws within same production facilities.

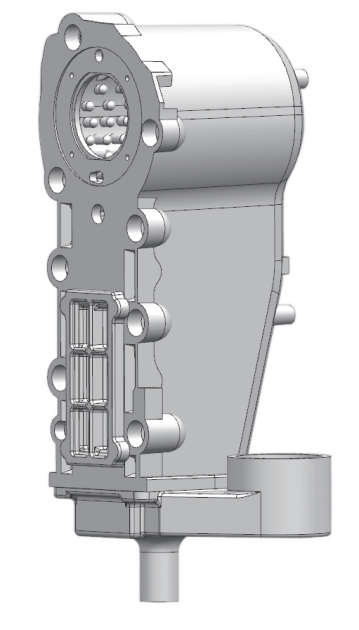

Prototyping divisions utilize 3D printed sand molds to validate geometries within 72 hours, significantly accelerating development cycles for hydraulic system manifolds. Production cells configured for low-volume copper alloy castings (15-200 units) maintain permanent tooling alongside flexible CNC machining centers. Digitized process controls automatically adjust pouring parameters for different materials transitioning between duplex stainless steel batches and nickel-aluminum bronze components without cross-contamination.

Material Performance Across Casting Techniques

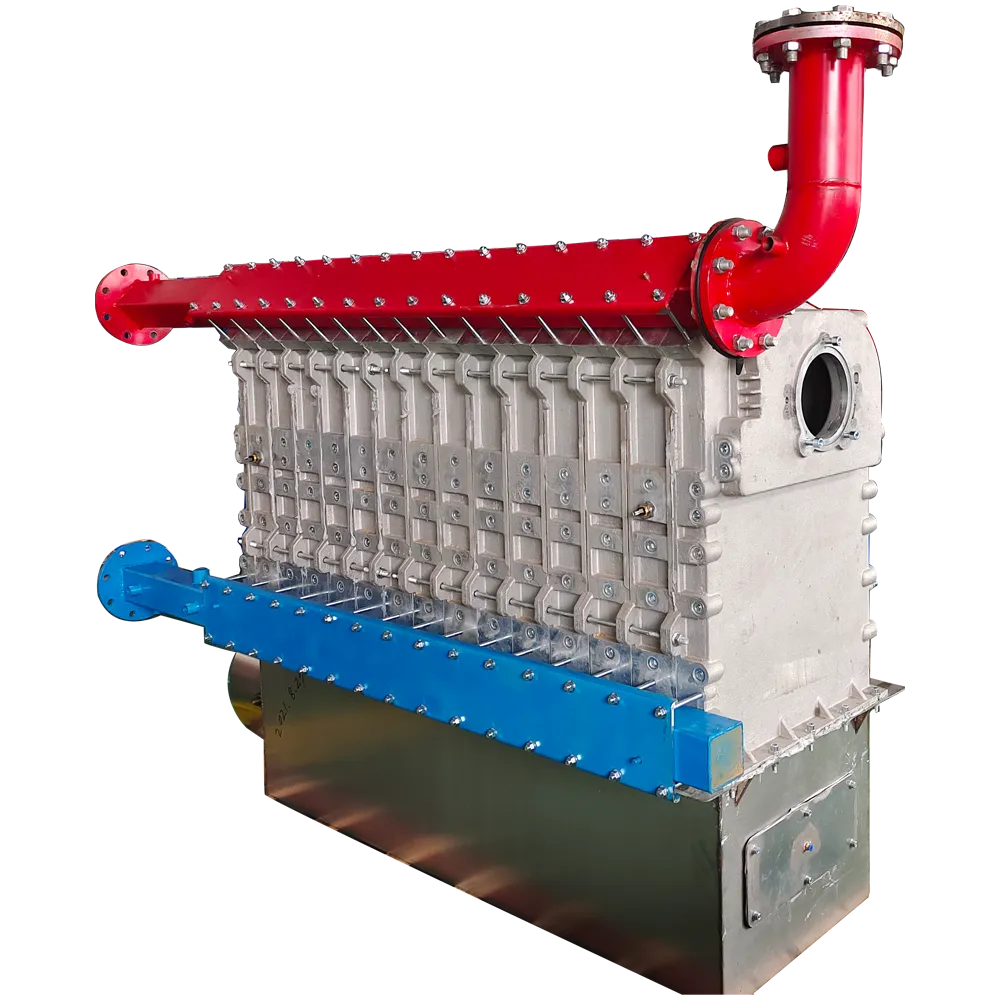

Material selection significantly impacts component performance with ASTM A536-84 Grade 80-55-06 ductile iron demonstrating 550MPa tensile strength in sand-cast gearboxes, outperforming typical grey iron alternatives by 140%. For corrosion resistance, investment-cast CF8M stainless components withstand salt spray testing exceeding 1,500 hours while maintaining pressure integrity above 2,400 PSI. Thermal conductivity advantages make die cast copper alloy components preferred for heat exchanger applications despite 38% higher material costs.

Dimensional stability comparisons reveal resin sand castings maintain ±0.3mm tolerances across 1-meter dimensions, sufficient for conveyor system frames. Precision investment castings achieve ±0.13mm accuracy essential for aerospace actuation systems, while pressure die cast aluminum components maintain positional tolerances within 0.05mm for automotive transmission housings requiring exact bearing alignments.

Automotive Component Implementation Case Studies

Tier 1 supplier validation documents showcase investment cast stainless steel turbocharger housings enduring 1,200°C exhaust gases while maintaining structural integrity across 500 thermal shock cycles. Electric vehicle manufacturers increasingly specify vacuum-processed ductile iron motor housings with integrated cooling channels that decrease assembly part count by 60% while improving thermal dissipation by 45%.

Aftermarket brake system producers report 21% reduction in warranty claims after transitioning to austempered ductile iron (ADI) caliper brackets through Chinese foundries certified under IATF 16949. Die-cast aluminum battery trays produced through wholesale casting foundries achieve dimensional consistency within 0.4mm across 900mm spans, critical for automated module assembly. Integrated machining centers now perform coordinate boring on 35,000-ton press frames previously requiring separate contract manufacturing arrangements.

Quality Verification and International Compliance

Chinese foundries serving regulated industries maintain NADCAP-accredited metallurgical labs performing spectrochemical analysis every 20 melts to confirm AISI 4140 steel chemistry. Dimensional validation employs blue light scanners capturing over 850,000 data points per casting, ensuring compliance with ASME Y14.5 standards. Quality tracking systems assign unique identification numbers tracing each stainless steel valve body from raw material certification through final pressure testing.

Environmental management systems certified to ISO 14001 govern responsible brass alloy production including closed-loop water treatment and thermal reclamation of spent foundry sand. Continuous improvement initiatives utilizing Six Sigma methodologies have reduced machining non-conformances on CNC-processed castings by 78% over four years. Material test reports consistently document mechanical properties exceeding ASTM A703 supplementary requirements for pressure-retaining components.

Steel Casting Quality Assurance in Precision Manufacturing

Leading Chinese foundries have invested over $120 million collectively in automated inspection technologies specifically for high-performance steel casting applications including phased-array ultrasonic testing for wind turbine hubs and radiography systems certifying military-grade ductile iron components. Production documentation packages for aerospace investment castings regularly exceed 400 pages including micrograph analysis of grain structure and certified chemical composition reports from independent laboratories.

Future development remains focused on Industry 4.0 integration where real-time statistical process control prevents dimensional drift during long-run brass fixture production. Strategic expansion targets precision carbon & alloy steel casting for hydraulic applications requiring EN 10213 certification while continuing technical advancement in stainless steel investment casting for the food processing and pharmaceutical sectors.

(steel casting)

FAQS on steel casting

Q: What types of casting processes does your Chinese foundry specialize in?

Q: What types of casting processes does your Chinese foundry specialize in?

A: We offer a full range of services including sand casting, investment casting, and die casting. This allows us to handle diverse materials like stainless steel, grey iron, brass, and copper. Precision machining can also be added to meet complex part requirements.

Q: Can you produce carbon & alloy steel precision castings in China?

Q: Can you produce carbon & alloy steel precision castings in China?

A: Yes, our foundry specializes in carbon steel and alloy steel precision castings using investment casting techniques. We ensure tight tolerances and complex geometries for demanding applications. Strict quality control guarantees consistent performance.

Q: Do you offer wholesale stainless steel casting foundry services in China?

Q: Do you offer wholesale stainless steel casting foundry services in China?

A: Absolutely, we provide wholesale stainless steel casting solutions for high-volume orders. Our facilities support various grades like 304/316 for corrosion resistance and strength. Competitive pricing is assured through optimized production processes.

Q: What materials can you cast for sand and investment casting projects?

Q: What materials can you cast for sand and investment casting projects?

A: We cast steel, grey iron, stainless steel, brass, and copper. Sand casting handles large iron or steel components, while investment casting delivers precision for intricate alloys. Material selection is tailored to your mechanical and environmental needs.

Q: Is machining included with your die casting services?

Q: Is machining included with your die casting services?

A: Yes, we provide integrated die casting with machining parts for finished components. This includes CNC machining, drilling, and surface finishing. One-stop service reduces lead times and ensures dimensional accuracy for assembly-ready products.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025