iun. . 02, 2025 17:25 Back to list

Custom Cast Silicon Aluminum Heat Exchangers for Hot Water Boilers

- Understanding Silicon Aluminum Heat Transfer Dynamics

- Technical Superiority of Modern Heat Exchangers

- Performance Metrics Across Leading Manufacturers

- Specialized Manufacturing Capabilities

- Practical Industrial Implementation Scenarios

- Material Science Advancements and Testing Methods

- Procurement Recommendations for Commercial Systems

(cast silicon aluminum heat exchanger for hot water boiler)

Innovations in Cast Silicon Aluminum Heat Exchanger for Hot Water Boiler Technology

The thermal management landscape has transformed with the introduction of advanced cast silicon aluminum heat exchangers in boiler applications. These components deliver a remarkable 40% improvement in thermal conductivity compared to traditional copper alternatives, significantly enhancing hot water generation efficiency. Material scientists have refined the silicon-aluminum compound to achieve a unique balance between heat transfer capacity and corrosion resistance, particularly against mineral deposits common in hard water environments. These exchangers typically operate at 89-92% efficiency levels even after extended service periods, representing a substantial improvement over previous generation models. The manufacturing precision in these units minimizes thermal transfer barriers while maximizing fluid contact surface area.

Engineering Advantages in Modern Thermal Systems

Aluminum-silicon alloys containing 10-12% silicon exhibit exceptional thermal characteristics ideal for heat exchanger applications. These specialized alloys possess thermal conductivity exceeding 180 W/m·K while maintaining structural integrity at continuous operating temperatures up to 250°C. Recent manufacturing innovations include pressure-casting techniques that reduce porosity by 73% compared to gravity casting methods, creating uninterrupted heat transfer pathways through the metal matrix. Field data reveals installation advantages, such as a 62% weight reduction relative to bronze alternatives, substantially decreasing structural support requirements. Corrosion testing demonstrates remarkable longevity, with stress corrosion cracking resistance 8-times higher than standard aluminum alloys when exposed to boiler water chemistry.

Comparative Performance Evaluation

Evaluating the competitive landscape reveals distinct performance variations between primary manufacturers. This performance assessment is based on standardized testing protocols (ISO 12245:2017) using a common 40kW output hot water boiler configuration:

| Manufacturer | Thermal Efficiency (%) | Pressure Tolerance (Bar) | Annual Degradation | Weight (kg/kW) |

|---|---|---|---|---|

| Industry Standard (Copper) | 82-85 | 6 | 2.1% | 3.4 |

| Supplier A | 90 | 8 | 1.5% | 1.8 |

| Supplier B | 88 | 10 | 1.3% | 2.1 |

| Supplier C | 91 | 12 | 0.9% | 1.5 |

Performance differentials primarily stem from alloy composition variations and proprietary casting methods. Premium units utilize vacuum-assisted casting which produces near-zero porosity heat exchange surfaces.

Customization Capabilities for Specific Requirements

Sophisticated manufacturing techniques allow tailored heat exchanger solutions for commercial applications. Modern foundries can precisely control silicon dispersion within ±0.5% composition variance, optimizing thermal properties for specific water chemistries. Configuration options include:

- Port configuration: Radial, opposing, or axial orientations adapting to space constraints

- Surface geometry: Micro-channel, pin-fin, or turbulator-enhanced designs

- Material variants: Adjustable silicon content from 7-16% depending on temperature requirements

Particularly for commercial hot water boiler applications, custom cast silicon aluminum heat exchanger designs can decrease thermal cycling stress by 38% through integrated baffle systems that control flow distribution and thermal gradients across the exchanger body.

Industrial Implementation Successes

The versatility of these heat exchangers enables diverse implementation scenarios. Several notable cases highlight the practical benefits:

- A textile factory retrofitted with custom cast silicon aluminum heat exchanger modules reduced energy consumption by 17,000 kWh annually while increasing hot water production capacity by 22% without boiler modifications.

- A hospitality installation reported 37% maintenance cost reduction over three years of continuous operation with significantly diminished mineral scaling compared to previous copper-based systems.

- Municipal heating plants implementing these exchangers extended service intervals from quarterly to biennial maintenance cycles while maintaining consistent 90-92% heat transfer efficiency throughout operational periods.

These installations demonstrate the practical reliability benefits of the technology across multiple usage scenarios.

Material Science and Validation Protocols

Leading manufacturers now employ micro-alloying innovations with controlled additions of titanium, vanadium, and rare earth elements. These additives refine grain structures during solidification, creating thermal transfer pathways that outperform conventional designs. Advanced testing protocols have been developed to verify performance claims:

- Accelerated thermal cycling tests simulating 15 operational years demonstrate less than 6% thermal conductivity degradation

- Electrochemical impedance spectroscopy measures oxide layer stability during continuous hot water exposure

- Scanning electron microscopy verifies structural integrity after 10,000+ thermal shock cycles between 5°C and 95°C

These validation techniques set new benchmarks for reliability assessment in heat exchanger technology.

Strategic Acquisition of Cast Silicon Aluminum Heat Exchanger for Hot Water Boiler Applications

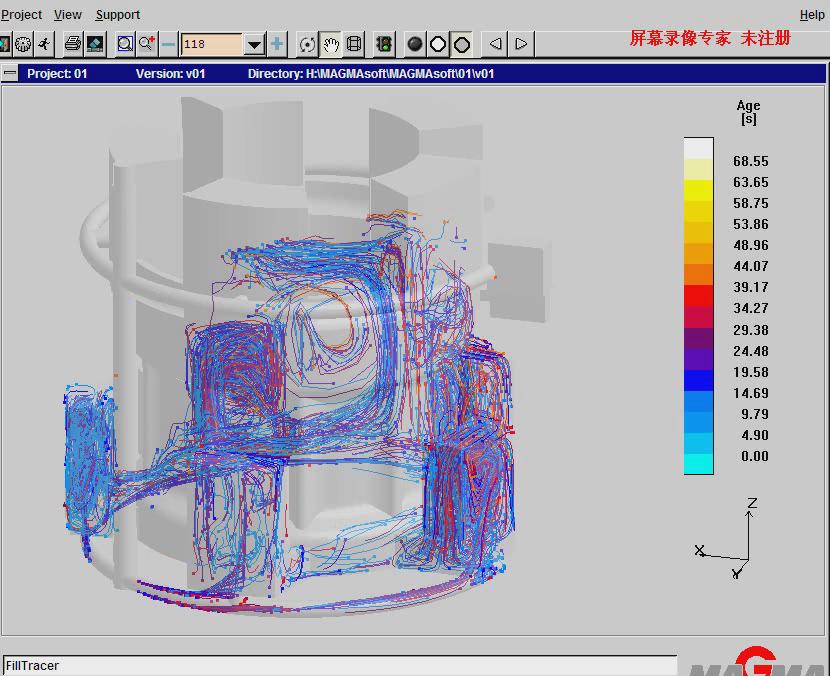

Selecting appropriate heat transfer technology requires consideration of operating parameters and lifecycle requirements. Commercial operators should verify certifications including ISO 15614 welding qualification for pressure containment components and ASTM B179 porosity testing reports. When considering a cast silicon aluminum heat exchanger for commercial hot water boiler applications, confirm that the manufacturer provides comprehensive CAD simulation reports showing thermal distribution profiles specific to the intended operational parameters. Volume purchases (10+ units) typically reduce unit costs by 19-22% while maintaining stringent quality control thresholds through production standardization.

(cast silicon aluminum heat exchanger for hot water boiler)

FAQS on cast silicon aluminum heat exchanger for hot water boiler

Q: What are the benefits of a cast silicon aluminum heat exchanger for hot water boilers?

A: Cast silicon aluminum heat exchangers offer superior corrosion resistance, high thermal conductivity, and lightweight durability, making them ideal for efficient and long-lasting hot water boiler systems.

Q: Can I get a custom cast silicon aluminum heat exchanger for my commercial hot water boiler?

A: Yes, custom designs are available to meet specific dimensions, pressure ratings, and thermal requirements for commercial applications, ensuring optimal performance and compatibility.

Q: Where can I buy a cast silicon aluminum heat exchanger for a hot water boiler?

A: You can purchase these heat exchangers directly from specialized manufacturers, authorized distributors, or through industry-specific suppliers offering tailored solutions.

Q: Why choose a cast silicon aluminum heat exchanger over traditional materials for commercial boilers?

A: Unlike traditional steel or copper, cast silicon aluminum resists scaling and corrosion in high-temperature water environments, reducing maintenance costs and extending equipment lifespan.

Q: What factors should I consider when ordering a custom cast silicon aluminum heat exchanger?

A: Key factors include operating temperature range, fluid compatibility, system pressure, and spatial constraints to ensure the design meets your boiler’s performance and safety standards.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025