Дек . 15, 2024 19:21 Back to list

ductile iron pipe mold bottom ring factories

The Role of Ductile Iron Pipe Mold Bottom Rings in Manufacturing

In the realm of manufacturing, particularly in the production of ductile iron pipes, the importance of quality molds cannot be overstated. Among various components in the mold assembly, the bottom ring of the mold plays a crucial role in ensuring the effectiveness and efficiency of the casting process. This article explores the significance of ductile iron pipe mold bottom rings, the manufacturing process, and the advantages they bring to the pipe production industry.

Understanding Ductile Iron and Its Applications

Ductile iron, also known as spheroidal graphite iron or nodular cast iron, is a type of cast iron that exhibits remarkable strength and ductility. It is widely used in various applications, including water and sewer pipes, because of its excellent mechanical properties, corrosion resistance, and ability to withstand high pressures. The demand for ductile iron pipes has surged due to their suitability for underground infrastructure, offering longevity and performance superior to many alternatives.

The Function of Mold Bottom Rings

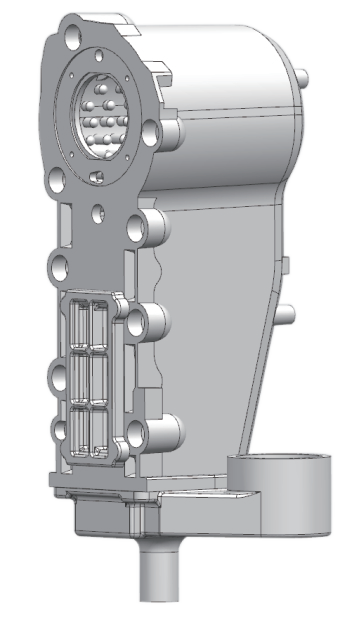

Mold bottom rings are integral components of the casting molds used for ductile iron pipe formation. These rings help to contain the molten iron during the pouring process, ensuring that the material fills the mold accurately and evenly. A well-designed bottom ring not only contains the molten material but also contributes to the overall integrity of the mold. It must withstand the considerable weight of the iron while maintaining precise dimensions to guarantee the final product’s quality.

Manufacturing Process of Ductile Iron Pipe Mold Bottom Rings

The manufacturing of ductile iron pipe mold bottom rings involves several critical steps

1. Material Selection High-quality iron alloys are chosen for their strength and durability. The characteristics of the material directly impact the ring's resistance to thermal stress and mechanical wear.

2. Mold Design Engineers design the bottom ring with intricate attention to detail. This includes considerations for the thickness, dimensions, and aeration features, which facilitate the escape of gases, ensuring a smooth casting process.

3. Casting Process The bottom rings are usually produced through sand casting or more advanced techniques such as investment casting. The chosen method affects the surface finish and dimensional accuracy of the final product.

ductile iron pipe mold bottom ring factories

4. Heat Treatment Post-casting heat treatment may be employed to enhance the mechanical properties of the bottom ring, such as increasing toughness and ductility.

5. Quality Control Each bottom ring undergoes rigorous inspection to ensure it meets the specified standards. This includes checking for dimensional accuracy, surface defects, and overall integrity.

Advantages of High-Quality Bottom Rings

Investing in high-quality ductile iron pipe mold bottom rings offers numerous advantages

- Enhanced Casting Quality A well-manufactured bottom ring ensures uniform filling of the mold, reducing the likelihood of defects such as voids or misalignment in the final pipe product.

- Increased Efficiency Durable bottom rings extend the lifespan of the mold, reducing downtime caused by wear and tear. This leads to increased productivity and cost savings for manufacturers.

- Improved Safety High-quality rings can better withstand the thermal and mechanical stresses of the casting process, reducing the risk of accidents and injuries in the manufacturing facility.

- Sustainability By optimizing the mold design and functionality, manufacturers can produce more efficient ductile iron pipes, contributing to sustainable construction practices and improved infrastructure resilience.

Conclusion

The ductile iron pipe mold bottom ring is a vital element in the manufacturing process of pipes that serve critical infrastructure needs. By ensuring a high-quality, efficient casting process, these rings contribute to the overall integrity and durability of ductile iron pipes. As the demand for reliable piping systems continues to grow, the role of superior mold components, like bottom rings, becomes increasingly significant in the industry. Investing in advanced manufacturing techniques and materials for these components will undoubtedly lead to the production of better, more sustainable ductile iron pipes, ultimately benefiting communities worldwide.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025