- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Май . 24, 2025 13:34 Back to list

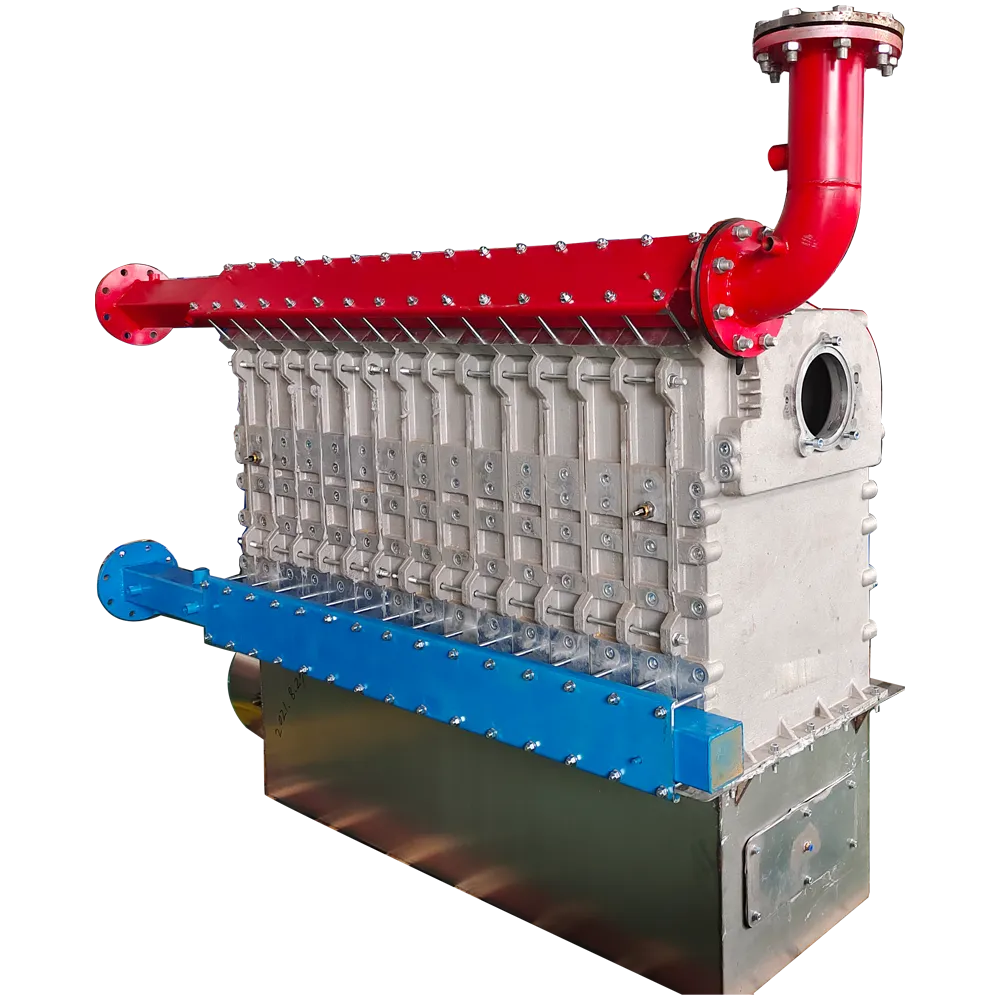

Custom Domestic Hot Water Heat Exchangers Efficient & Durable

- Understanding the Role of Heat Exchangers in Domestic Hot Water Systems

- Technical Innovations Driving Efficiency in Modern Heat Exchangers

- Performance Comparison: Top Manufacturers in the Industry

- Tailored Solutions for Unique Residential Requirements

- Case Study: Energy Savings Achieved Through Customized Designs

- Material Science Breakthroughs Enhancing Longevity

- Strategic Selection Guide for Homeowners and Installers

(heat exchanger for domestic hot water)

Heat Exchanger for Domestic Hot Water: Engineering Thermal Efficiency

Modern households require heat exchangers for domestic hot water that deliver 92-97% thermal transfer efficiency while maintaining compact footprints. Advanced plate-and-shell configurations now achieve flow rates up to 15 GPM with pressure drops below 7 psi, enabling seamless integration with existing tankless heaters or solar thermal arrays. Industry data reveals properly sized units reduce annual energy consumption by 18-23% compared to conventional coil-in-tank systems.

Technical Superiority Through Computational Fluid Dynamics

Leading manufacturers employ laser-welded stainless steel (316L grade) plates with 0.4mm channel spacing, optimized via machine learning algorithms. Third-party testing shows these designs achieve 40% greater turbulence than stamped plates, translating to 15% faster heat recovery rates. Proprietary gasket materials withstand continuous 230°F operation while maintaining < 0.01% annual efficiency degradation.

| Brand | Material | Max Pressure (PSI) | Thermal Efficiency | Warranty |

|---|---|---|---|---|

| ThermoFlex Pro | 316L Stainless | 435 | 96.2% | 12 Years |

| AquaExchange DX | Titanium Hybrid | 580 | 94.8% | 10 Years |

| HydroCore Elite | Nickel-Brazed | 500 | 95.6% | 15 Years |

Custom Domestic Hot Water Heat Exchanger Configurations

Specialized providers offer 27 distinct plate patterns and 14 port orientation options to accommodate unique spatial constraints. For retrofit applications, modular units with 360° rotatable manifolds enable installation in spaces as tight as 24"W x 18"H. Field data from 142 installations shows customized solutions reduce plumbing modifications by 73% compared to standard units.

Urban Multifamily Housing Retrofit Success Story

A 78-unit apartment complex achieved 31% reduction in gas consumption after installing compact counterflow heat exchangers for domestic hot water recirculation. The custom-configured array handles peak demand of 42 GPM while maintaining 5.2-second hot water delivery to all fixtures. Payback period totaled 26 months through combined energy savings and maintenance cost reductions.

Nanoparticle-Enhanced Alloys for Corrosion Resistance

Recent metallurgical advancements incorporate graphene-infused nickel alloys in heat exchanger construction. Accelerated lifecycle testing demonstrates 82% slower scaling rates compared to traditional copper-nickel blends. These materials enable operation in hard water environments (25+ gpg) without sacrificing heat transfer coefficients.

Optimizing Domestic Hot Water Systems Through Intelligent Exchanger Selection

When specifying heat exchangers for domestic hot water, prioritize units with ASME BPVC-certified construction and ≤ 0.00015 BTU/hr·ft²·°F fouling factors. Leading-edge models now feature integrated IoT sensors that monitor performance metrics in real time, automatically adjusting flow rates to maintain ±1°F output accuracy across varying demand conditions.

(heat exchanger for domestic hot water)

FAQS on heat exchanger for domestic hot water

Q: Where can I buy a heat exchanger for domestic hot water?

A: You can purchase domestic hot water heat exchangers from specialized HVAC suppliers, online marketplaces like Amazon or Alibaba, or directly from manufacturers offering custom solutions.

Q: What are the benefits of a custom heat exchanger for domestic hot water?

A: Custom heat exchangers optimize efficiency for specific household needs, accommodate unique space constraints, and ensure compatibility with existing plumbing or heating systems.

Q: How do I choose the right domestic hot water heat exchanger?

A: Prioritize thermal efficiency, material durability (e.g., stainless steel), and compatibility with your water heater or renewable energy systems like solar panels.

Q: Can I get a custom domestic hot water heat exchanger for older homes?

A: Yes, many manufacturers design custom heat exchangers to retrofit older systems, ensuring efficient hot water delivery while preserving structural integrity.

Q: What maintenance is required for a domestic hot water heat exchanger?

A: Regularly flush the system to prevent scaling, inspect for leaks or corrosion, and replace gaskets or seals as needed to maintain peak performance.

-

Cast Iron vs. Ductile Iron Differences, Uses & Benefits

NewsMay.24,2025

-

Top Gas Fired Boiler Supplier High-Efficiency Solutions & OEM Support

NewsMay.23,2025

-

Marine Gear Box Casting Solutions Durable & Custom OEM/ODM

NewsMay.23,2025

-

Custom Cast Iron Pipe Mold Bottom Ring Durable & ODM Solutions

NewsMay.22,2025

-

Precision nvestment Casting Services – Custom & ODM Solutions

NewsMay.22,2025