Окт . 31, 2024 15:55 Back to list

Innovative Designs for High-Temperature Heat Exchanger Efficiency Improvements

High Temperature Heat Exchangers Advancements and Applications

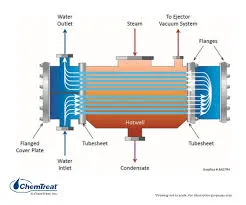

High temperature heat exchangers (HTHEs) play a crucial role in various industrial processes, enabling efficient heat transfer in systems that require elevated temperature operation. These specialized devices are designed to facilitate heat exchange between two or more fluids at high temperatures, often exceeding 300°C (572°F). As industries strive for greater efficiency, sustainability, and reduced energy consumption, the importance of HTHEs continues to grow.

One of the primary applications of high temperature heat exchangers is in the power generation industry, particularly in combined cycle and gas turbine power plants. In these systems, exhaust gases from combustion processes reach very high temperatures. HTHEs are employed to recover waste heat and convert it into usable energy, thus increasing the overall efficiency of the power plant. This not only maximizes energy output but also significantly lowers greenhouse gas emissions, making power generation more environmentally friendly.

Moreover, HTHEs are vital in chemical processing and petroleum refining. Many chemical reactions and distillation processes require elevated temperatures to optimize production rates and yields. Implementing high temperature heat exchangers can enhance thermal efficiency, reduce the energy necessary for heating, and promote more sustainable operational practices. For instance, HTHEs facilitate the recovery of heat from endothermic reactions, enabling heat to be reused in other parts of the plant.

high temperature heat exchanger

The design of high temperature heat exchangers is a complex engineering challenge. Materials must withstand not only high temperatures but also corrosion and fouling due to the fluids being processed. Advanced materials, such as superalloys and ceramic composites, are often employed to enhance the lifespan and reliability of these exchangers. Innovative designs, including compact heat exchangers and modular configurations, allow for improved heat transfer efficiency while minimizing space and weight.

Looking to the future, ongoing research and development in high temperature heat exchanger technology are focused on enhancing material performance, optimizing designs, and integrating advanced control systems. These innovations aim to address the growing demand for heat exchangers in high-temperature applications, especially as industries transition towards cleaner energy sources.

In conclusion, high temperature heat exchangers are indispensable components in various high-temperature applications, from power generation to chemical processing. Their ability to enhance energy efficiency while reducing environmental impact makes them a critical element for industries aiming to embrace sustainable practices. As technology continues to advance, the role of HTHEs will undoubtedly expand, further contributing to the efforts in promoting energy efficiency and sustainability across multiple sectors.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025