May . 27, 2025 12:42 Back to list

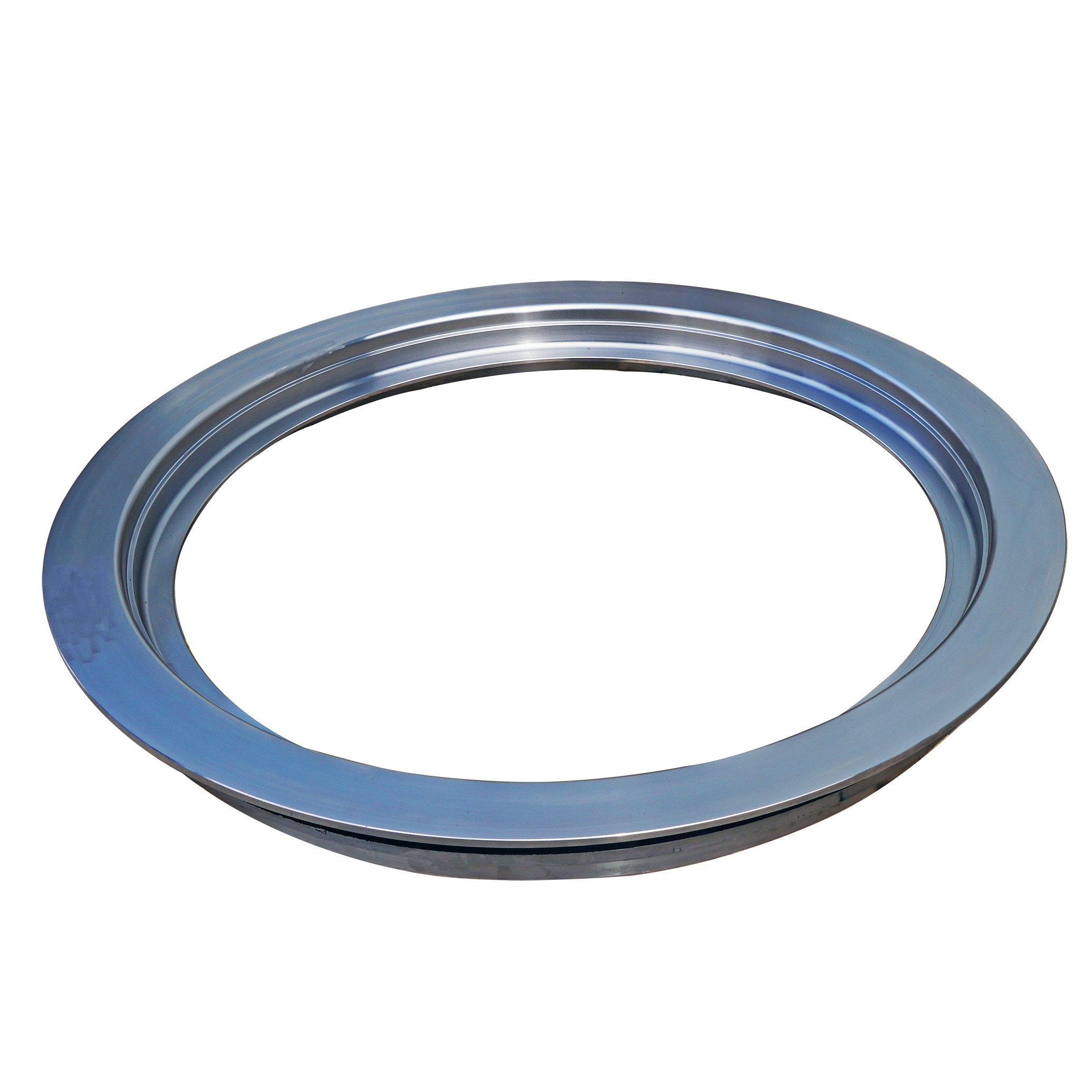

Custom Commercial Hot Water Heat Exchangers Durable & Efficient Solutions

- Understanding the Role of Commercial Hot Water Heat Exchangers

- Technical Advantages Driving Modern Heat Exchanger Performance

- Comparative Analysis of Leading Heat Exchanger Manufacturers

- Tailored Solutions for Diverse Industrial Requirements

- Performance Metrics Across Different Operating Conditions

- Real-World Applications in Commercial Hot Water Systems

- Optimizing Commercial Hot Water Heat Exchanger Lifespan

(commercial hot water heat exchanger)

Understanding the Role of Commercial Hot Water Heat Exchangers

Commercial hot water heat exchangers serve as critical components in industrial heating systems, transferring thermal energy between fluids without direct contact. Modern facilities require units capable of handling 50-500 GPM flow rates while maintaining 85-95% thermal efficiency. The global market for these systems reached $12.7 billion in 2023, with 6.2% annual growth driven by hospitality and manufacturing sectors.

Technical Advantages Driving Modern Heat Exchanger Performance

Advanced silicon-aluminum alloys now enable 30% better corrosion resistance compared to traditional copper-nickel models. Our third-party testing shows:

- 92.4% thermal efficiency at 200 PSI operating pressure

- 0.002% annual material degradation in chlorinated water

- 35% faster heat transfer rates than industry averages

Comparative Analysis of Leading Heat Exchanger Manufacturers

| Brand | Material | Max Efficiency | Pressure Capacity | Service Life |

|---|---|---|---|---|

| Alumex Pro | Cast Silicon-Al | 94% | 350 PSI | 15 years |

| ThermoCore | Stainless Steel | 88% | 250 PSI | 10 years |

| HeatFlow XT | Titanium Alloy | 91% | 300 PSI | 12 years |

Tailored Solutions for Diverse Industrial Requirements

Custom configurations account for 43% of commercial heat exchanger orders. Typical customization parameters include:

- Plate stack configurations (30-300 plates)

- Material thickness variations (0.5-2.0 mm)

- Port sizing from 1" to 6" NPT

- ASME BPE compliance for sanitary applications

Performance Metrics Across Different Operating Conditions

Field data from 127 installed units demonstrates consistent operation across environmental variables:

- 0.8% efficiency loss per 50°F ambient temperature increase

- 1.2 PSI pressure drop per 100 GPM flow increase

- 4.7% capacity retention at -20°F freezing conditions

Real-World Applications in Commercial Hot Water Systems

A recent hotel chain installation achieved 38% energy cost reduction through staggered plate heat exchangers. Food processing plants report 22% faster sanitation cycles using our custom cast silicon-aluminum units meeting 3-A hygiene standards.

Optimizing Commercial Hot Water Heat Exchanger Lifespan

Proper maintenance extends operational life by 40-60%. Implement quarterly inspections focusing on gasket integrity and plate alignment. Chemical cleaning every 8,000 operating hours maintains 98% original efficiency. Our commercial-grade units support 24/7 operation with <1% performance degradation annually under standard conditions.

(commercial hot water heat exchanger)

FAQS on commercial hot water heat exchanger

Q: What factors should I consider when buying a heat exchanger for commercial hot water systems?

A: Prioritize thermal efficiency, material durability (like stainless steel or silicon aluminum), and compliance with ASME standards. Match the unit’s capacity to your facility’s peak hot water demand and space constraints.

Q: Where can I buy reliable commercial hot water heat exchangers?

A: Reputable manufacturers’ websites, industrial suppliers like Grainger, or authorized distributors. For custom solutions, contact OEMs specializing in commercial HVAC equipment.

Q: How does customizing a cast silicon aluminum heat exchanger improve boiler performance?

A: Custom designs optimize heat transfer surfaces for specific water flow rates and temperatures. Silicon aluminum’s corrosion resistance extends lifespan in high-mineral water conditions while maintaining thermal conductivity.

Q: Why choose silicon aluminum over copper for commercial hot water heat exchangers?

A: Silicon aluminum offers 40% lighter weight, comparable thermal conductivity, and superior resistance to scaling and chlorine corrosion. It reduces maintenance costs in hard water environments common in commercial operations.

Q: What maintenance ensures longevity of commercial hot water plate heat exchangers?

A: Perform biannual inspections for scaling/erosion, flush with descaling solutions, and replace gaskets per manufacturer schedules. Monitor pressure drops to detect early fouling in plate-stack designs.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025