Dec . 05, 2024 14:11 Back to list

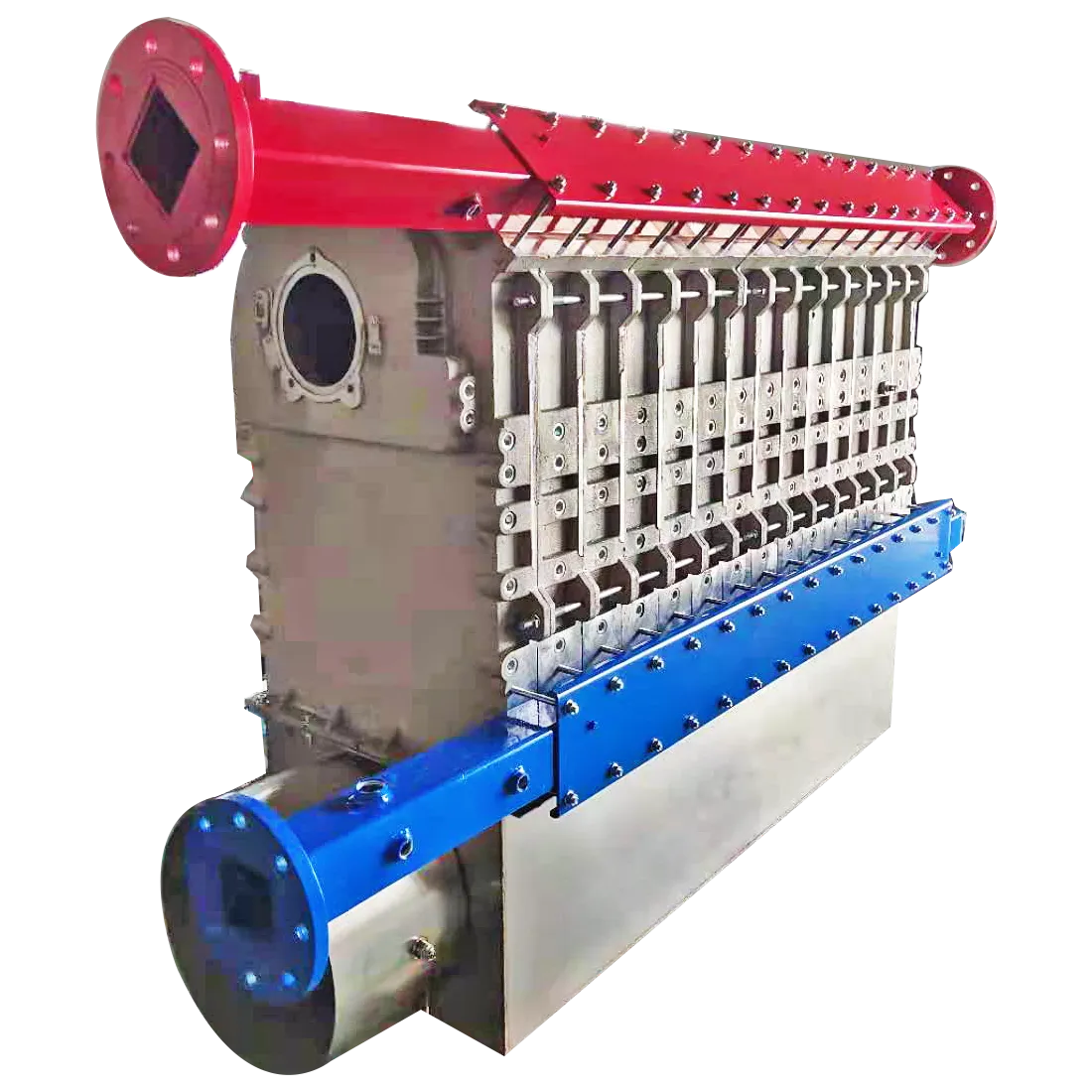

malleable iron castings

Understanding Malleable Iron Castings

Malleable iron castings are a vital component in the world of manufacturing and engineering, offering a unique combination of strength, ductility, and machinability. Derived from white cast iron through a process known as malleabilization, these castings are valued for their ability to withstand stress and deformation without breaking, making them suitable for various applications in multiple industries.

The Manufacturing Process

The development of malleable iron begins with the casting of white iron, which has a high carbon content and a cementite structure. To transform white iron into malleable iron, the castings undergo a heat treatment process. This involves heating the white cast iron to a temperature of around 900°C to 1000°C for an extended period, followed by a slow cooling process. This heat treatment causes the cementite to decompose, resulting in a microstructure composed of ferrite and graphite. The formation of this microstructure imparts the ductile properties that characterize malleable iron.

Properties and Advantages

Malleable iron castings exhibit several key properties that make them highly desirable in various applications

1. Ductility and Toughness Unlike brittle cast iron, malleable iron can deform under stress, allowing it to absorb energy without fracturing. This property makes it particularly useful in applications subject to shock or impact.

2. Strength Malleable iron has a high tensile strength, providing the ability to withstand substantial loads without yielding. This strength is critical in components that must endure rigorous mechanical forces.

malleable iron castings

4. Corrosion Resistance Although not inherently corrosion-resistant, surface treatments can be applied to enhance the lifespan of malleable iron components, helping to protect against environmental factors.

5. Cost-Effectiveness Compared to other high-strength materials, malleable iron is often more economically viable, providing a balance between performance and cost.

Applications

The unique properties of malleable iron make it suitable for a wide range of applications. It is commonly used in the manufacturing of

- Automotive Components Parts such as suspension components, gears, and brackets benefit from the ductility and strength of malleable iron. - Construction Malleable iron is used in fittings, brackets, and pipes due to its excellent wear resistance and strength. - Agricultural Equipment Components that must endure high stress and harsh conditions often utilize malleable iron for its reliability. - Utilities Valves and other fittings in water and gas distribution systems are often made from malleable iron due to its durability and corrosion resistance.

Future Trends

The demand for malleable iron castings is expected to grow as industries seek materials that offer both performance and cost-efficiency. Innovations in manufacturing processes and heat treatment techniques may further enhance the properties of malleable iron, opening up new possibilities for its application. Additionally, as sustainability becomes a key focus, the recycling of malleable iron scrap presents opportunities for reducing production costs and environmental impacts.

Conclusion

Malleable iron castings stand as a testament to the ever-evolving landscape of materials science. With their unique blend of strength, ductility, and machinability, they continue to play a crucial role in various industries. As technology advances, malleable iron is poised to remain a prominent choice for engineers and manufacturers around the globe. Understanding its properties and applications is essential for anyone involved in the preparation and production of cast iron components.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025