Dec . 02, 2024 06:12 Back to list

stamp concrete pipe mould bottom ring manufacturers

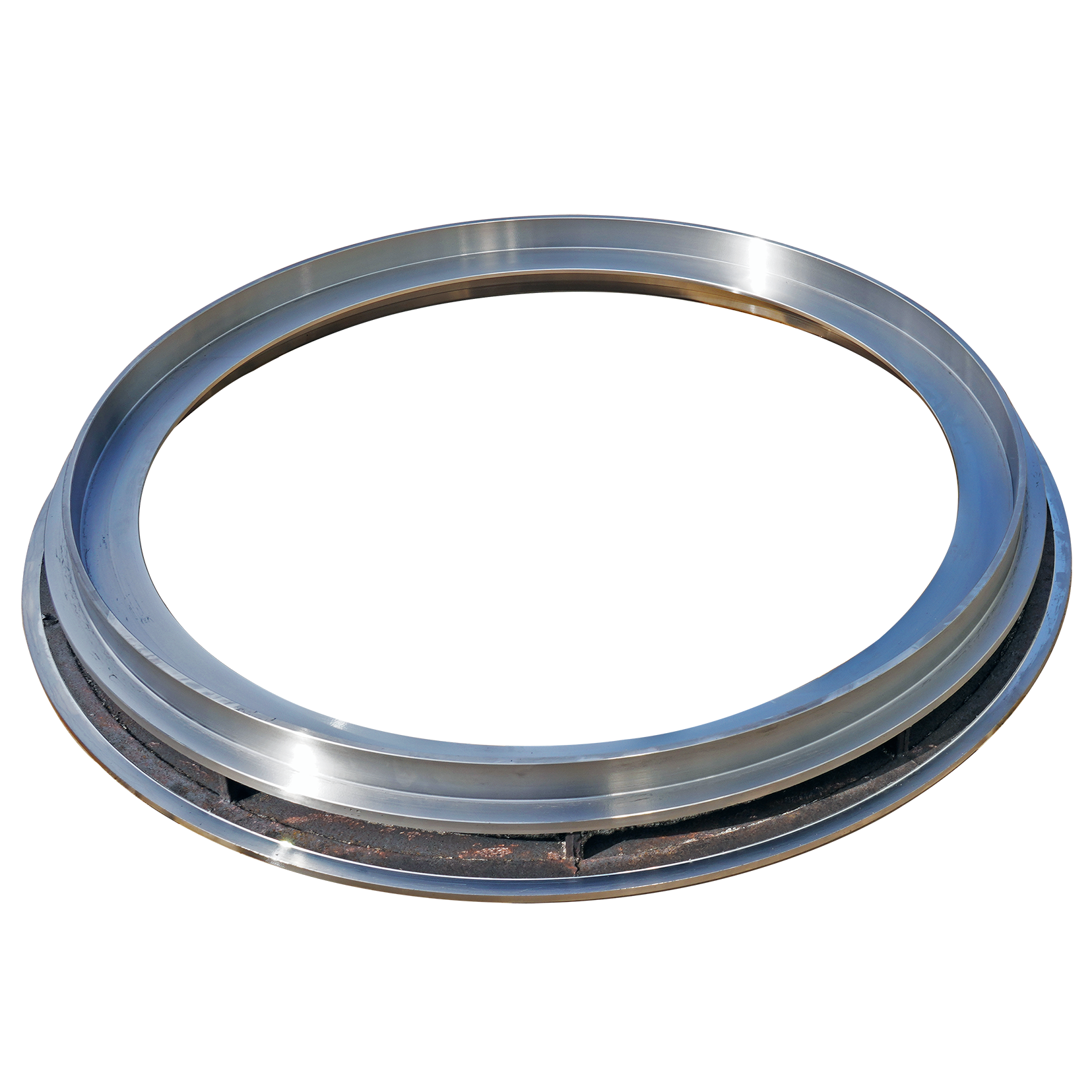

Stamp Concrete Pipe Mould Bottom Ring Manufacturers A Vital Component in Modern Construction

In the realm of modern construction, the necessity for durable and efficient materials is paramount. Among these, concrete remains a stalwart choice due to its strength, longevity, and versatility. One of the critical components in the manufacturing of concrete products—such as pipes used in drainage, storm water management, and sewage systems—are the molds used in their production. Specifically, bottom ring molds play a crucial role in ensuring the structural integrity and precise dimensions of these concrete pipes. This article delves into the importance of stamp concrete pipe mould bottom ring manufacturers and their contribution to the construction industry.

The Role of Bottom Ring Moulds

Bottom ring molds are essential for creating the base of concrete pipes. They are designed to shape the circumference and interior profile of the pipe while providing a stable base during the concrete curing process. Moreover, the quality and precision of the mould can significantly influence the overall quality of the final product. This is where manufacturers come into play, producing molds that meet stringent engineering specifications and industry standards.

Advantages of Concrete Pipes

Concrete pipes are widely chosen for various applications due to their numerous advantages. They offer exceptional resistance to various environmental stresses, including corrosion, abrasion, and soil conditions. Additionally, their robustness allows for the installation in challenging terrains, making them particularly suitable for urban infrastructure. Moreover, concrete pipes are cost-effective over their lifespan, as they often require less maintenance compared to other materials. The production of these pipes hinges on the quality of their molds, highlighting the significance of reliable manufacturers in this niche market.

Quality Standards in Manufacturing

Manufacturers of stamp concrete pipe mould bottom rings must adhere to rigorous quality standards. The molds should be engineered for strength and precision, capable of withstanding the high pressures associated with concrete pouring and curing. This entails the use of high-quality materials, such as steel or specialized reinforced composites, that can endure the rigors of the manufacturing process.

stamp concrete pipe mould bottom ring manufacturers

Moreover, the design of the mould plays a vital role in ensuring proper concrete flow and uniformity during production. Advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) machining are often employed by manufacturers to achieve high levels of precision.

Trends and Innovations

As the construction industry evolves, so too do the techniques and technologies used by manufacturers. One notable trend is the increasing emphasis on sustainability. Manufacturers are now exploring eco-friendly materials and processes that reduce waste and lower the carbon footprint associated with construction activities. Innovations such as 3D printing of moulds and the use of recycled materials reflect the industry's commitment to sustainability.

Additionally, manufacturers are adopting advanced technologies like automation and robotics to enhance production efficiency. This not only speeds up manufacturing processes but also improves consistency in product quality, which is crucial for ensuring that the resultant concrete pipes meet the specified requirements.

The Importance of Collaboration

Collaboration between manufacturers, engineers, and contractors is essential for the successful implementation of concrete pipe projects. Effective communication ensures that the molds provided meet the specific project needs and comply with local regulations. Manufacturers often work closely with their clients to understand their unique challenges and provide tailored solutions that enhance the end product's performance.

Conclusion

In conclusion, stamp concrete pipe mould bottom ring manufacturers play an indispensable role in the construction industry. Their ability to produce high-quality, precision-engineered molds directly impacts the efficiency and durability of concrete pipes. As trends evolve, manufacturers are also adapting to meet sustainability goals and harness technological advancements, ensuring that they remain relevant in a competitive market. By investing in quality molds and fostering partnerships within the construction ecosystem, these manufacturers contribute significantly to the longevity and reliability of essential infrastructure components that promote community development and environmental sustainability.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025