Tet . 22, 2024 06:29 Back to list

Exporters of Dry Cast Reinforced Concrete Pipe Molds and Bottom Rings

The Rising Demand for Dry Cast Reinforced Concrete Pipe Mould Bottom Rings A Global Perspective on Exporters

In the construction and infrastructure industry, the demand for durable and efficient materials is ever-increasing. One of the critical components that meet these demands is the dry cast reinforced concrete pipe mould bottom ring. These products are gaining significant traction among exporters, driven by the need to enhance the quality and longevity of concrete pipes used in various applications, including sewer systems, drainage, and industrial applications.

Understanding Dry Cast Reinforced Concrete Pipes

Dry cast reinforced concrete pipes (RCP) are manufactured using a process that ensures consistency, strength, and longevity. The 'dry cast' method involves producing concrete that has a lower water-to-cement ratio, which results in denser and stronger concrete. This technique is essential for reinforcing pipes that can withstand heavy loads and harsh environmental conditions. The bottom ring of the pipe mould is critical, as it supports the structure and maintains the integrity of the pipe during both the manufacturing process and its end-use.

Importance of the Bottom Ring

The bottom ring in concrete pipe moulds is a vital part of the overall structure, providing stability and shape during the curing process. When functioning effectively, the bottom ring ensures that the concrete pipes retain their intended shape and can be removed easily from the mould without damage. As a result, manufacturers that specialize in RCPs prioritize the quality of their mould bottom rings, as this directly impacts the durability and efficiency of the pipes produced.

Market Trends and Export Opportunities

In recent years, there has been a notable shift in the global construction market towards using reinforced concrete systems for infrastructure projects. The increasing focus on sustainable and resilient building practices has further propelled the demand for high-quality concrete pipe systems, including their moulds. Exporters of dry cast reinforced concrete pipe mould bottom rings are tapping into this trend, supplying products that meet the stringent standards required in various regions.

An integral aspect contributing to the growth of this market is the urbanization phenomenon. As cities expand, the need for robust drainage systems, sewer lines, and water transport infrastructure has surged, leading to a spike in demand for concrete pipes. Exporters who offer high-quality, reliable mould bottom rings are positioned to benefit from this trend, especially in emerging markets where infrastructure development is a priority.

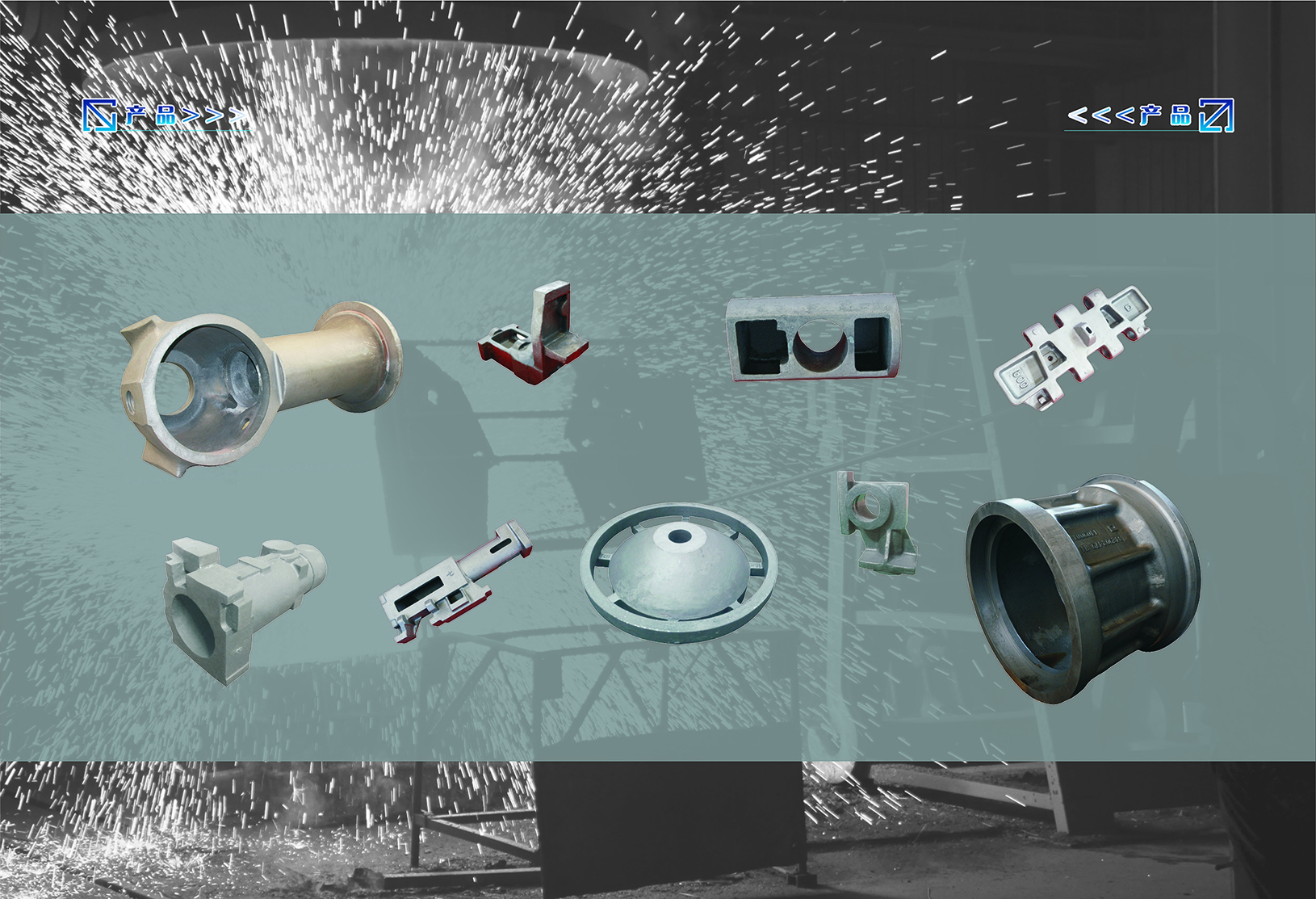

dry cast reinfored concrete pipe mould bottom ring exporters

Key Players and Competitive Landscape

The market for dry cast reinforced concrete pipe mould bottom rings witnesses participation from various global players. Many companies specialize in manufacturing and exporting these products, focusing on innovation and technology to enhance the quality of their offerings. Leading manufacturers often invest in research and development to create more efficient designs and materials that reduce production costs while maintaining high standards.

In addition to quality, the negotiation of competitive pricing is crucial for exporters. With growing competition globally, exporters must ensure that they offer not only the highest quality but also reasonable pricing to secure their market positions. Furthermore, establishing strong partnerships with local distributors and contractors can help exporters gain a competitive edge in various regions.

Environmental Considerations

As the construction industry shifts towards more sustainable practices, the environmental impact of construction materials has become a focal point. Dry cast reinforced concrete pipe mould bottom rings are often preferred for their durability, longevity, and lower maintenance requirements. These factors contribute to reduced waste and lower overall environmental impact in infrastructure projects.

Exporters are increasingly highlighting the eco-friendliness of their products in marketing campaigns. By promoting the sustainability of dry cast concrete systems, they can cater to the growing demand from environmentally conscious clients and regulators who prioritize green building practices.

Conclusion

The emerging global market for dry cast reinforced concrete pipe mould bottom rings presents lucrative opportunities for exporters. With a combination of urbanization, demand for durable infrastructure, and a shift towards sustainable construction practices, the future looks bright for those who can offer high-quality, cost-effective solutions. As the industry continues to evolve, remaining adaptable and innovative will be key for exporters aiming to thrive in this competitive landscape. By focusing on quality, sustainability, and market trends, exporters can position themselves as leaders in this crucial segment of the construction industry.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025