сеп . 28, 2024 19:36 Back to list

Concrete Pipe Mold Pallet Manufacturer Specializing in Stamping Solutions for Enhanced Durability

The Importance of Quality in Stamping Concrete Pipe Mould Pallet Manufacturing

In the construction industry, the quality of materials used directly affects the durability and strength of the final product. One crucial component in the production of concrete pipes is the mould pallet, especially in the context of stamping concrete pipe moulds. The efficiency and reliability of these mould pallets can significantly influence the production process and the overall output quality. This article explores the importance of high-quality stamping concrete pipe mould pallets and highlights some key aspects that manufacturers must consider to ensure excellent production results.

Understanding Stamping Concrete Pipe Moulds

Concrete pipes are essential in various applications, particularly in sewage systems, stormwater management, and drainage solutions. The use of stamping concrete pipe moulds allows manufacturers to produce pipes with excellent surface finishes and dimensional accuracy. Mould pallets serve as the foundation for the stamping process, supporting the concrete mix as it sets and gains its final shape.

A quality mould pallet must incorporate designs that allow for easy handling, consistent mold release, and durability over continuous use. Manufacturers often use abrasion-resistant materials that endure the high pressures and stresses encountered during the stamping process, ensuring that the moulds maintain their intended shape over time.

Key Features of Quality Mould Pallets

1. Material Selection The choice of materials for constructing mould pallets cannot be understated. Commonly, durable metals or high-quality plastics are used to withstand repetitive stamping actions and the chemical reactions involved with concrete curing. Ideally, the material should resist corrosion, wear, and tear to extend the life cycle of the pallet.

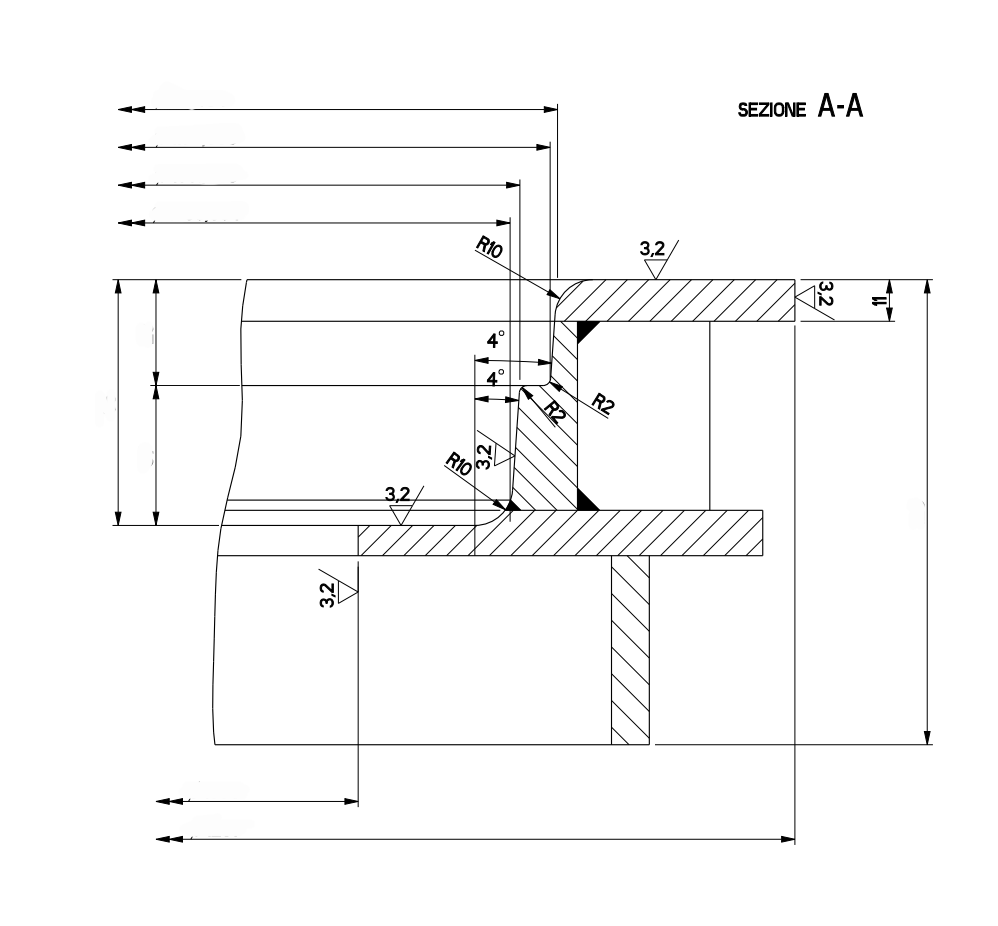

2. Precision Engineering For mould pallets to function effectively, they must be engineered with precision. This involves careful consideration of the mould dimensions, tolerances, and alignment features. Precision ensures that the final concrete pipes meet industry standards and client specifications, ultimately leading to customer satisfaction.

3. Ease of Use Mould pallets should be designed to facilitate ease of use in the production environment. This includes features such as lightweight construction, ergonomic handles, and modular designs that simplify assembly and disassembly. A user-friendly pallet design can significantly enhance productivity and reduce downtimes during the manufacturing cycle.

stamping concrete pipe mould pallet manufacturer

4. Interchangeability The ability to interchange moulds is another critical feature of high-quality mould pallets. Manufacturers should consider developing standardised pallets that can work with multiple mould designs. This flexibility not only reduces costs but also enhances operational efficiency by allowing for quicker production changes.

5. Heat Resistance Another important aspect to consider is the heat resistance of the mould pallets. Concrete curing can generate significant heat, and the pallets must be able to withstand these conditions without deforming or degrading. High-performance pallets can maintain their structural integrity and functionality even under excessive heat exposure.

Sustainability Considerations

As the construction industry moves towards sustainability, manufacturers of stamping concrete pipe mould pallets must also focus on eco-friendly practices. Utilizing recyclable materials, reducing waste during the manufacturing process, and investing in energy-efficient operations are becoming increasingly important. Sustainable practices not only help the environment but can also attract clients who prioritize responsible sourcing.

Choosing a Reliable Manufacturer

To achieve high-quality stamping concrete pipe mould pallets, it is crucial to choose the right manufacturer. Companies should look for manufacturers with a proven track record in producing durable and effective mould pallets. A responsive supplier with excellent customer support can also make a significant difference, ensuring that any issues with the pallets are addressed promptly.

Conclusion

In conclusion, the role of stamping concrete pipe mould pallets in the production of quality concrete pipes cannot be overlooked. Selecting high-quality mould pallets is essential for achieving consistent results, improving efficiency, and ensuring the longevity of the final products. Manufacturers should focus on material selection, precision engineering, ease of use, and sustainable practices to excel in this competitive market. By prioritizing these aspects, the construction industry can guarantee enhanced performance and reliability in its concrete products.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025