Dec . 25, 2024 17:33 Back to list

China's Leading Expert in Steel Investment Casting Manufacturing Solutions for Your Needs

Specializing in Steel Investment Casting A Leader in China's Industry

In the rapidly evolving landscape of manufacturing, steel investment casting has emerged as a pivotal process, particularly in China, where the demand for high-quality, precision-engineered components is ever-growing. A specialist in steel investment casting exemplifies the marriage of advanced technology, skilled craftsmanship, and market-oriented production, setting itself apart in a highly competitive industry.

Steel investment casting, also known as lost-wax casting, is a sophisticated method that offers numerous advantages over traditional casting techniques. This process allows for the creation of intricate and complex geometries that are difficult to achieve with other methods. The ability to produce high-tolerance components makes investment casting preferable in industries such as aerospace, automotive, and machinery manufacturing.

China stands as a global leader in the casting industry, driven by its robust manufacturing infrastructure, technological advancements, and a skilled workforce. As a specialist in this field, companies have invested heavily in machinery and technology that enhance precision and efficiency. The use of computer numerical control (CNC) machines and advanced software for modeling and simulation has streamlined production processes, ensuring that the final products meet stringent quality standards.

One of the key advantages of steel investment casting is its material versatility. Steel, known for its strength, durability, and resistance to wear, is a preferred choice for components subjected to high stress and harsh environments. By leveraging high-grade stainless steels and alloy steels, manufacturers can produce parts that are not only strong but also corrosion-resistant, which is essential for many applications. This versatility also allows for the customization of products tailored to specific client needs, making the investment casting specialist a sought-after partner for businesses seeking high-performance parts.

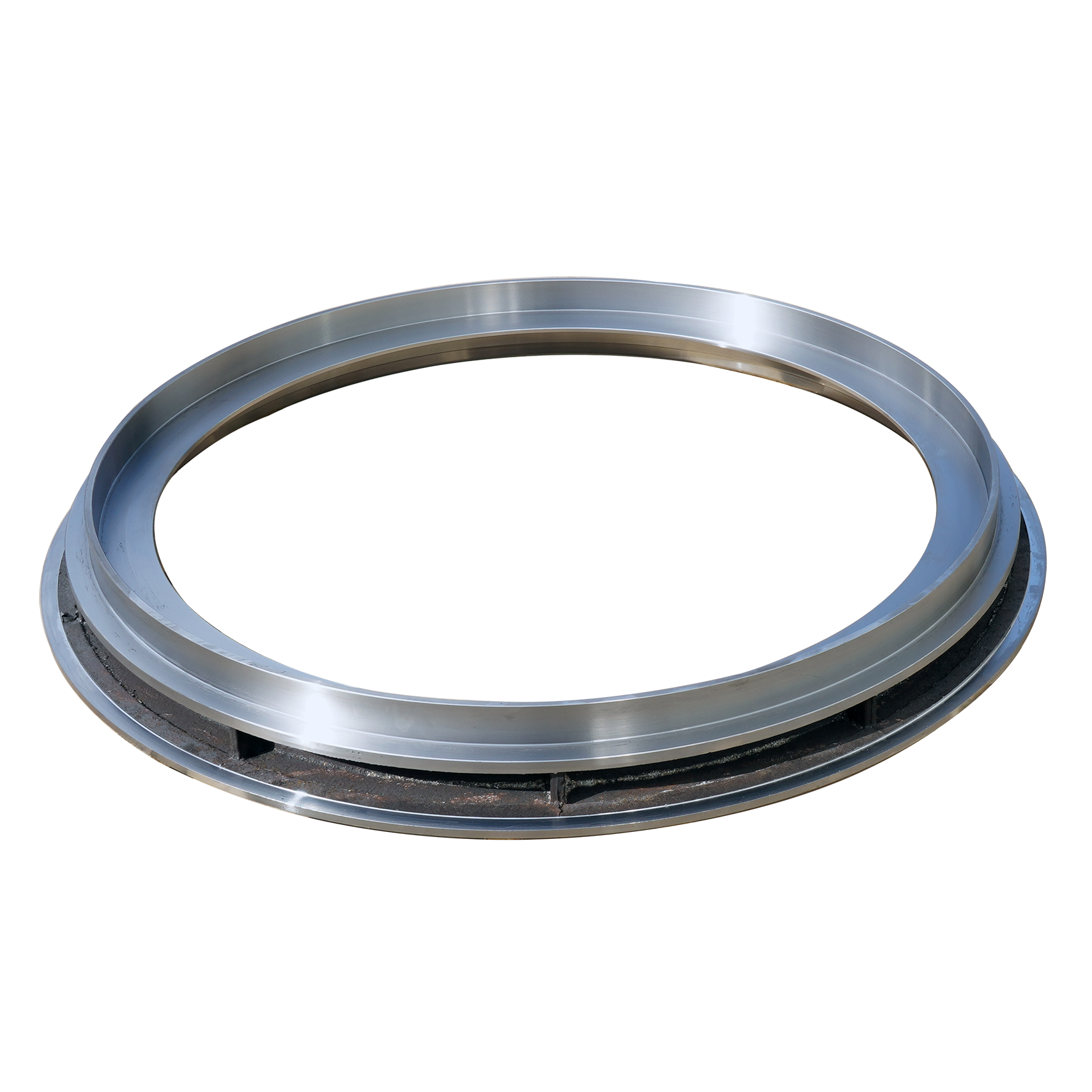

china specialist in steel investment casting factory

Moreover, an aspect that sets a steel investment casting factory apart is its commitment to sustainability and environmental responsibility. Modern casting facilities are increasingly adopting practices and technologies aimed at reducing waste, recycling materials, and minimizing energy consumption. This not only helps in complying with regulatory standards but also appeals to environmentally-conscious consumers who prefer to engage with businesses that demonstrate corporate responsibility.

Quality control is at the heart of any specialized foundry. Investment casting companies in China implement rigorous quality assurance processes to maintain high standards. From the selection of raw materials to the final inspection of finished products, each step in the casting process is meticulously monitored. Advanced non-destructive testing methods, such as X-ray and ultrasonic testing, are utilized to ensure that each component is free from defects and meets technical specifications.

In addition to quality and precision, customer service is a critical component of success in the investment casting industry. A true specialist in steel investment casting fosters strong relationships with clients, offering technical support and consultation throughout the design and manufacturing process. This customer-centric approach not only enhances client satisfaction but also promotes long-term partnerships and repeat business.

As the global market continues to grow, the demand for steel investment casting in China is expected to rise. The ongoing advancements in technology, coupled with a commitment to quality and sustainability, position China as a pivotal player in the investment casting arena. Companies that embrace innovation while maintaining high production standards will undoubtedly lead the charge in meeting both local and international demands for high-quality steel components.

In conclusion, a specialist in steel investment casting represents the forefront of manufacturing excellence in China. With the ability to produce complex, high-quality components efficiently and sustainably, these manufacturing powerhouses are well-equipped to meet the challenges of the future, solidifying their role as key contributors to the global manufacturing landscape. As industries evolve, the expertise and capabilities of steel investment casting specialists will play a crucial role in shaping the future of manufacturing.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025