Septemba . 02, 2024 12:59 Back to list

Precision Casting of Carbon & Alloy Steel in China

Carbon and Alloy Steel Casting for Precision Casting in China

The casting industry in China has witnessed remarkable growth over the past few decades, positioning the country as a global leader in manufacturing various components for diverse applications. Among the wide array of materials utilized within this sector, carbon and alloy steels have emerged as two highly important categories, notably for precision casting processes.

Carbon steel, which is an iron-carbon alloy, comprises various percentages of carbon, affecting its hardness, strength, and overall performance. Typically, carbon content in carbon steel ranges from 0.05% to 2.0%, allowing manufacturers to tailor the material properties according to the end-use requirements. The lower the carbon percentage, the more ductile and malleable the steel becomes, making it ideal for applications where easy forming is necessary. On the other hand, higher carbon content increases hardness and tensile strength, suitable for applications requiring enhanced durability and resistance to wear.

Alloy steels, comprised of additional elements such as manganese, nickel, chromium, and molybdenum, offer specific mechanical properties that carbon steels may lack. These alloys are designed to improve strength, hardness, toughness, and corrosion resistance, which are pivotal in precision casting. For instance, manganese improves hardenability, while chromium enhances oxidation resistance and overall durability, making alloy steels suitable for harsh operating environments. This versatility allows for the production of complex and intricate shapes that meet the stringent tolerances required in precision engineering.

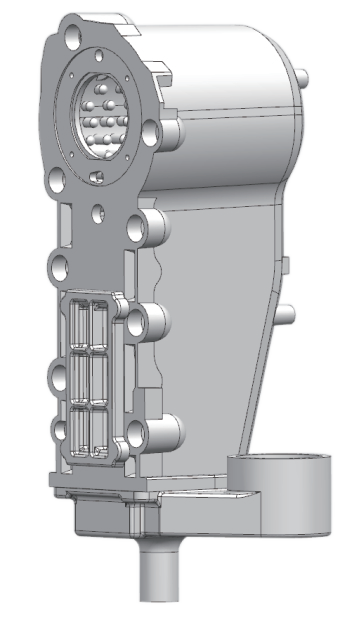

carbon & alloy steel casting for precision casting in china

China's expertise in precision casting techniques further amplifies the advantages of using carbon and alloy steels. Modern manufacturing processes, including sand casting, investment casting, and die casting, facilitate the production of high-quality components with exceptional dimensional accuracy. Investment casting, in particular, enables the fabrication of complex geometries with smooth surface finishes, increasing the efficiency of subsequent machining operations. The precision achieved through these methods is essential in industries like aerospace, automotive, and machinery manufacturing, where components must adhere to stringent specifications.

Moreover, the extensive supply chain and robust infrastructure in China support the casting industry. The availability of local raw materials, coupled with advanced manufacturing technologies, allows for cost-effective production without compromising quality. As a result, Chinese manufacturers have established a strong reputation for delivering high-quality carbon and alloy steel castings, catering to both domestic and international markets.

In conclusion, the dynamic interplay of carbon and alloy steel properties, coupled with advanced precision casting techniques, positions China as a formidable player in the global casting market. As industries continue to evolve, the demand for precision-engineered components will only grow, solidifying the role of carbon and alloy steels in high-performance applications. Through ongoing innovation and investment, China is poised to maintain its leadership in precision casting, ensuring that it meets the evolving needs of diverse sectors worldwide.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025