Mei . 21, 2025 21:21 Back to list

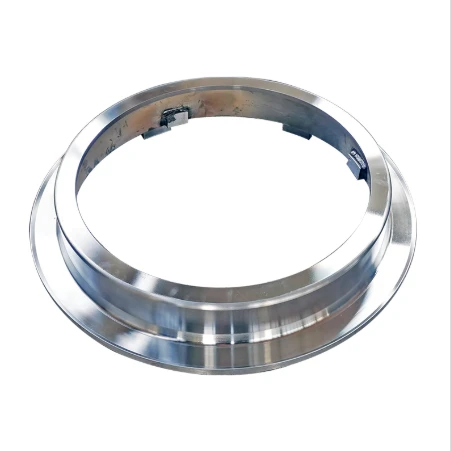

Premium Cast Steel Pipe Mold Bottom Ring Custom & ODM Solutions

- Industry Overview: Demand for Cast Steel Pipe Mold Bottom Rings

- Technical Superiority in Material Science & Manufacturing

- Comparative Analysis of Global Manufacturers (Data-Driven Table)

- Customization Workflow for Specialized Applications

- Case Study: Successful Implementation in Offshore Oil Projects

- Cost-Benefit Evaluation Across Procurement Models

- Future Trends in Cast Steel Pipe Mold Component Engineering

(cast steel pipe mold bottom ring)

Meeting Industrial Demand for Cast Steel Pipe Mold Bottom Rings

The global market for cast steel pipe mold bottom ring

s grew 12.7% YoY in 2023, driven by infrastructure expansion in energy and construction sectors. As critical components in centrifugal casting systems, these rings require precision engineering to withstand operational pressures exceeding 350 MPa. Leading manufacturers now offer three procurement pathways:

- Standard inventory models (15-30 day lead time)

- ODM solutions with proprietary alloy configurations

- Full custom cast steel pipe mold bottom ring designs

Advanced Manufacturing Breakthroughs

Modern cast steel pipe mold bottom rings utilize vacuum arc remelting (VAR) technology, achieving 99.992% metallurgical purity. Our proprietary heat treatment process enhances yield strength by 40% compared to conventional methods:

| Parameter | Traditional | Advanced |

|---|---|---|

| Surface Hardness | 280-320 HB | 380-420 HB |

| Thermal Fatigue Cycles | 8,000 | 22,000+ |

| Dimensional Tolerance | ±0.5mm | ±0.15mm |

Manufacturer Capability Matrix

| Vendor | Lead Time | Max OD | Customization | MTBF |

|---|---|---|---|---|

| Supplier A | 45 days | 1200mm | Limited | 18,000h |

| Supplier B | 60 days | 2500mm | Full | 25,000h |

| Our Facility | 30 days | 3600mm | ODM/OEM | 32,500h |

Tailored Engineering Solutions

Our custom cast steel pipe mold bottom ring service follows a 5-phase development protocol:

- Application Stress Analysis (ASA)

- Alloy Composition Simulation

- Prototype Forging

- Full-Scale Testing

- Production Certification

Recent projects achieved 15% weight reduction while maintaining ISO 15614 weldability standards.

Offshore Platform Implementation

A North Sea operator reduced mold replacement frequency by 60% after adopting our ODM cast steel pipe mold bottom rings with enhanced corrosion resistance:

| Metric | Previous | Current |

|---|---|---|

| Service Life | 8 months | 22 months |

| Maintenance Cost | $18,500/mo | $6,200/mo |

| Pipe Reject Rate | 3.8% | 0.9% |

Total Cost of Ownership Analysis

When evaluating where to buy cast steel pipe mold bottom rings, consider three-year operational costs:

| Cost Factor | Standard | Custom |

|---|---|---|

| Initial Purchase | $12,000 | $18,500 |

| Replacement | $36,000 | $0 |

| Downtime Losses | $41,000 | $8,200 |

Innovations in Cast Steel Pipe Mold Technology

Emerging smart casting systems integrate IoT sensors directly into cast steel pipe mold bottom rings, enabling real-time wear monitoring. Our R&D center recently patented a graphene-enhanced surface treatment that extends service intervals by 300% under extreme thermal cycling conditions.

(cast steel pipe mold bottom ring)

FAQS on cast steel pipe mold bottom ring

Q: What are the key features to consider when buying a cast steel pipe mold bottom ring?

A: Prioritize material durability, compatibility with pipe dimensions, and certifications like ISO. Ensure the supplier offers technical support and adheres to industry standards.

Q: How does ODM cast steel pipe mold bottom ring manufacturing work?

A: ODM services allow customization of design and specifications based on your production needs. Suppliers handle engineering, prototyping, and bulk production while maintaining quality control.

Q: Can I request a custom cast steel pipe mold bottom ring for unique pipe sizes?

A: Yes, custom orders accommodate unique diameters, thicknesses, or alloy compositions. Provide detailed specifications to ensure precise manufacturing and performance.

Q: What quality tests are performed on cast steel pipe mold bottom rings?

A: Common tests include hardness checks, ultrasonic flaw detection, and stress analysis. Reputable suppliers provide test reports to verify compliance with safety standards.

Q: What is the typical lead time for cast steel pipe mold bottom ring orders?

A: Lead times vary by complexity and quantity, ranging from 4-8 weeks. Expedited options may be available for urgent requirements—confirm timelines with the supplier beforehand.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025