ก.ย. . 12, 2024 07:27 Back to list

Casting Part Supplier | High-Quality Custom Casting Solutions

The Role of Casting Part Suppliers in Modern Manufacturing

Casting is an essential process in manufacturing that transforms raw materials into shaped components through pouring molten metal into molds. As industries evolve and demand for precision and efficiency grows, the role of casting part suppliers becomes increasingly significant. These suppliers not only provide the necessary components but also contribute to the broader manufacturing ecosystem by ensuring high-quality production and streamlined processes.

Casting part suppliers offer a range of services, from prototyping to mass production. They typically specialize in various materials, including aluminum, iron, and steel, each serving distinct purposes depending on the application. For instance, lightweight aluminum castings are favored in the automotive industry for their fuel efficiency benefits, while iron castings are often used in heavy machinery due to their durability. Suppliers must constantly adapt to industry trends and technological advancements to meet evolving customer needs.

One critical aspect of casting part suppliers is their capability for customization. Manufacturers often require specific shapes, sizes, and tolerances that standard parts cannot fulfill. Suppliers with advanced capabilities in design and engineering can collaborate with clients to develop tailored solutions that fulfill exact specifications. This customization not only enhances product performance but also reduces time-to-market, providing a substantial competitive edge.

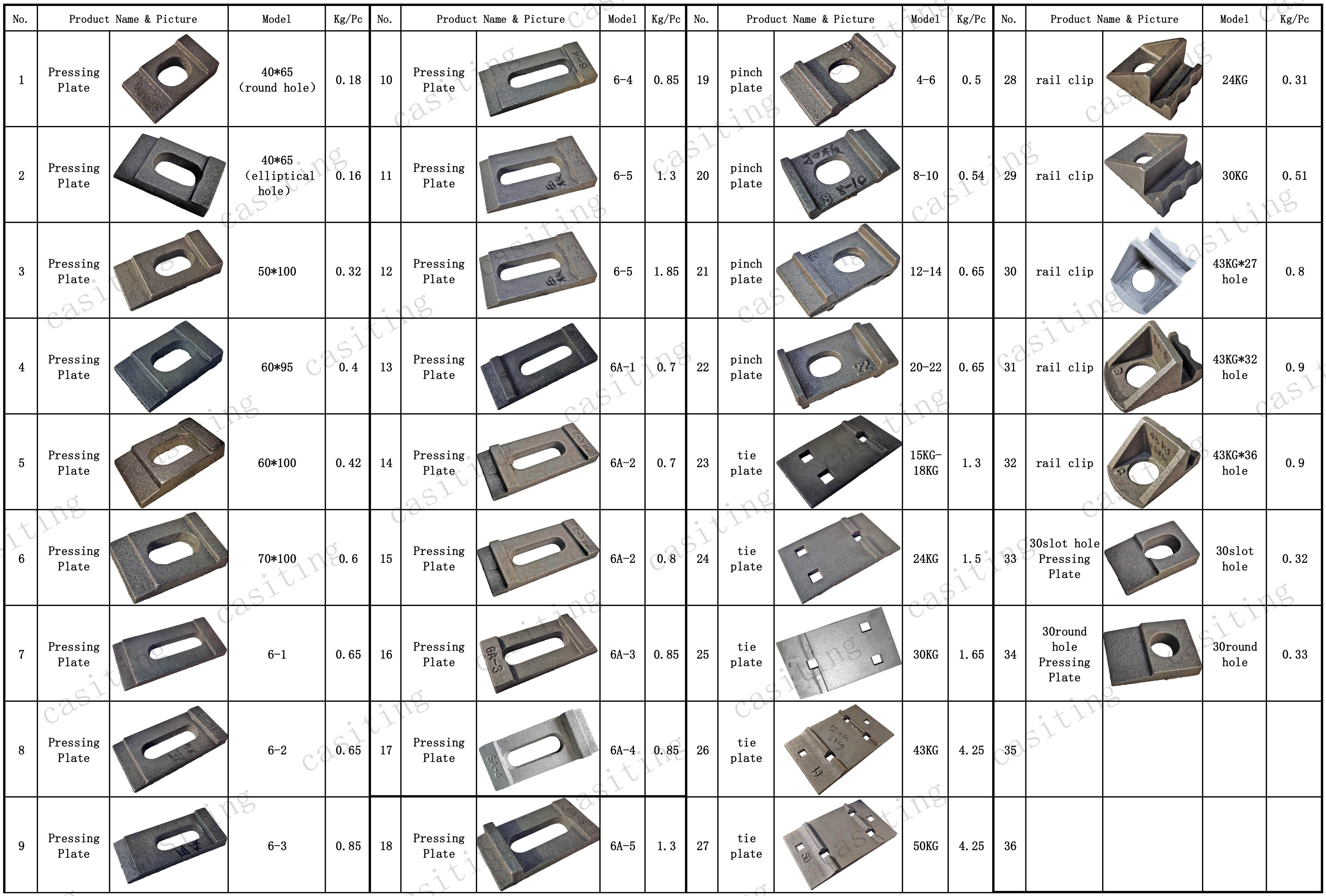

casting part supplier

Quality control is another vital responsibility of casting part suppliers. To ensure the integrity of their products, suppliers employ various testing methods such as ultrasonic testing, X-ray inspection, and hardness testing. By adhering to stringent quality standards, suppliers can minimize defects and improve the reliability of the components provided to manufacturers. This commitment to quality is crucial, especially in sectors like aerospace and medical devices where safety and precision are paramount.

Moreover, sustainability practices are becoming increasingly important in the casting industry. Suppliers are now exploring methods to reduce waste and minimize their environmental impact. This includes using recyclable materials, implementing energy-efficient processes, and minimizing emissions during production. Companies that prioritize sustainability not only enhance their reputation but also appeal to a broader customer base that values environmentally friendly practices.

In conclusion, casting part suppliers play a pivotal role in the manufacturing sector by providing essential components, ensuring quality, and embracing customization and sustainability. As industries continue to advance and integrate new technologies, the collaboration between manufacturers and casting part suppliers will be crucial in driving innovation and achieving operational excellence. The success of many products on the market today can be attributed to the expertise and capabilities of these suppliers, highlighting their indispensable contribution to modern manufacturing.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025