ธ.ค. . 11, 2024 11:43 Back to list

heat exchanger capacity

Understanding Heat Exchanger Capacity

Heat exchangers are critical components in various industrial processes, including power generation, chemical processing, and heating, ventilation, and air conditioning (HVAC) systems. Their primary function is to transfer heat between two or more fluids without mixing them. The effectiveness of a heat exchanger is often measured by its capacity. This article will explore the concept of heat exchanger capacity, its significance, factors influencing it, and some practical applications.

What is Heat Exchanger Capacity?

Heat exchanger capacity refers to the maximum amount of thermal energy that a heat exchanger can transfer from one fluid to another within a given period. It is typically expressed in units of power, such as kilowatts (kW) or British Thermal Units per hour (BTU/h). Understanding the capacity is crucial for designing efficient systems that can meet the thermal demands of various processes.

The capacity of a heat exchanger is influenced by several factors, including the temperature difference between the fluids, the flow rates, the heat transfer coefficients, and the physical characteristics of the exchanger, such as its surface area and material.

Importance of Heat Exchanger Capacity

The capacity of a heat exchanger is vital for ensuring that systems operate efficiently. If the capacity is too low, the heat exchanger may not provide adequate heating or cooling, leading to inefficiencies and potential damage to equipment. Conversely, an oversized heat exchanger may lead to unnecessary capital costs, increased energy consumption, and operational inefficiencies.

In industrial applications, calculating the required capacity based on the processes involved is essential. For instance, in a power plant, the heat exchanger must handle large amounts of heat generated from fuel combustion, transferring it to cooling water or steam. Proper capacity calculation ensures optimal performance and prevents equipment failure.

Factors Affecting Heat Exchanger Capacity

1. Temperature Difference The greater the temperature difference between the hot and cold fluids, the higher the potential heat transfer. Designers often strive to maintain significant temperature differences to maximize efficiency.

heat exchanger capacity

2. Flow Rates The flow rates of the fluids significantly impact the heat exchange process. Increased velocity enhances turbulence, which can improve the heat transfer coefficient, thereby increasing capacity.

3. Heat Transfer Area The surface area available for heat transfer is critical. Heat exchangers with larger surface areas, such as plate or finned-tube exchangers, can accommodate more heat transfer, thus increasing their capacity.

4. Fluid Properties The thermal conductivity, viscosity, and specific heat of the fluids also play a role in determining the heat exchanger's capacity. For example, fluids with higher specific heat can store and transport more heat.

5. Design Configuration The design type of the heat exchanger (e.g., shell-and-tube, plate, or air-cooled) and its configuration can significantly affect capacity. Each design has its advantages and limitations, depending on the application.

Applications of Heat Exchanger Capacity

Heat exchangers are found in various applications, each with unique requirements for capacity. In HVAC systems, heat exchangers regulate temperatures in buildings, affecting comfort and energy usage. In the food and beverage industry, they are used for pasteurization, where controlling temperatures is paramount for safety and quality.

In chemical processing, heat exchangers assist in controlling reactor temperatures, ensuring optimal reaction rates. Additionally, in the energy sector, they play a vital role in cooling systems for power plants, which must manage high thermal loads efficiently.

Conclusion

Heat exchanger capacity is a fundamental concept that determines the efficiency and effectiveness of thermal systems across multiple industries. Understanding the various factors that guide capacity calculations helps engineers and designers create systems that meet specific thermal requirements while minimizing costs and energy consumption. As industries continue to pursue sustainability and efficiency, the role of properly sized and effectively operating heat exchangers will only become more crucial.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

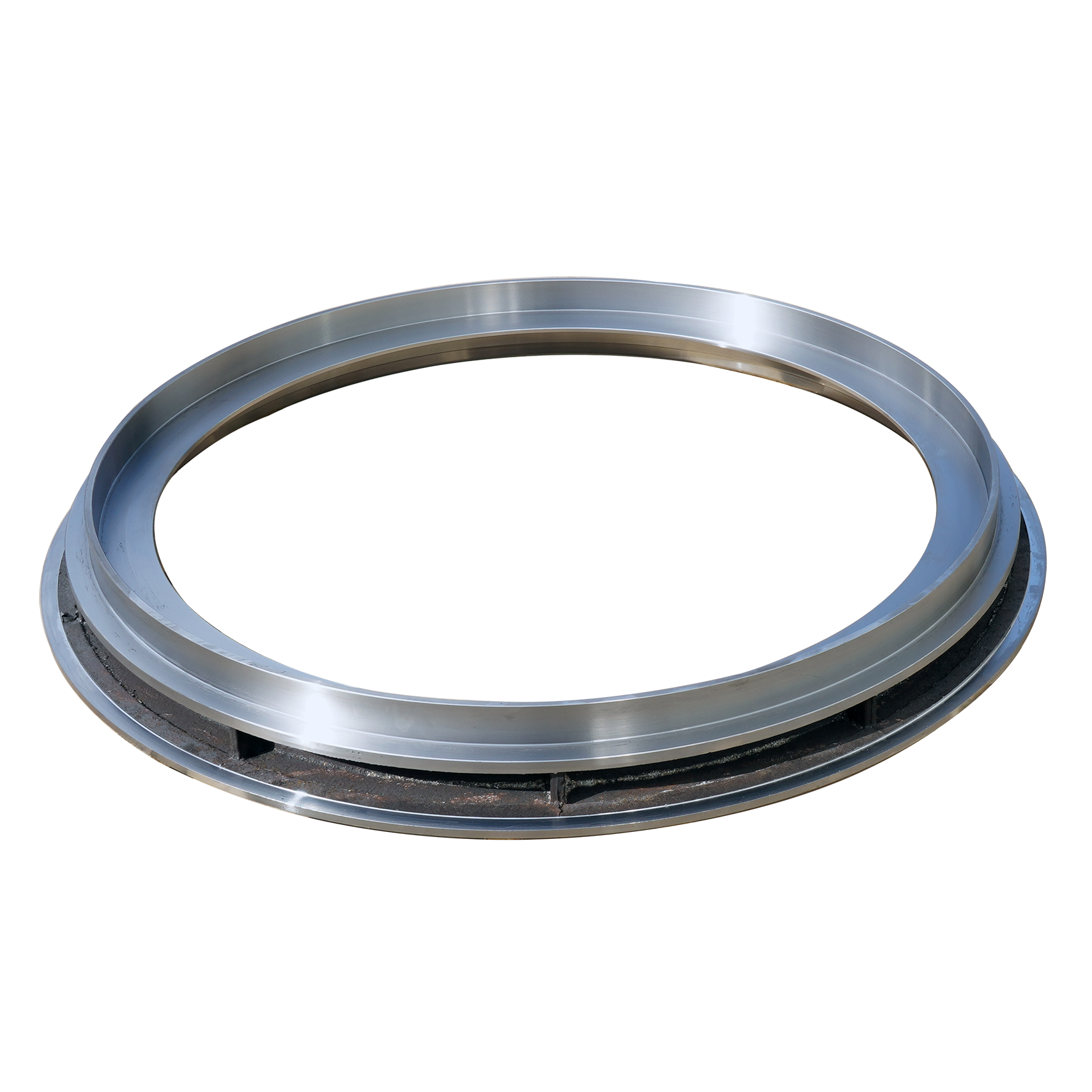

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025