Eyl . 22, 2024 21:08 Back to list

al cast mold and pattern

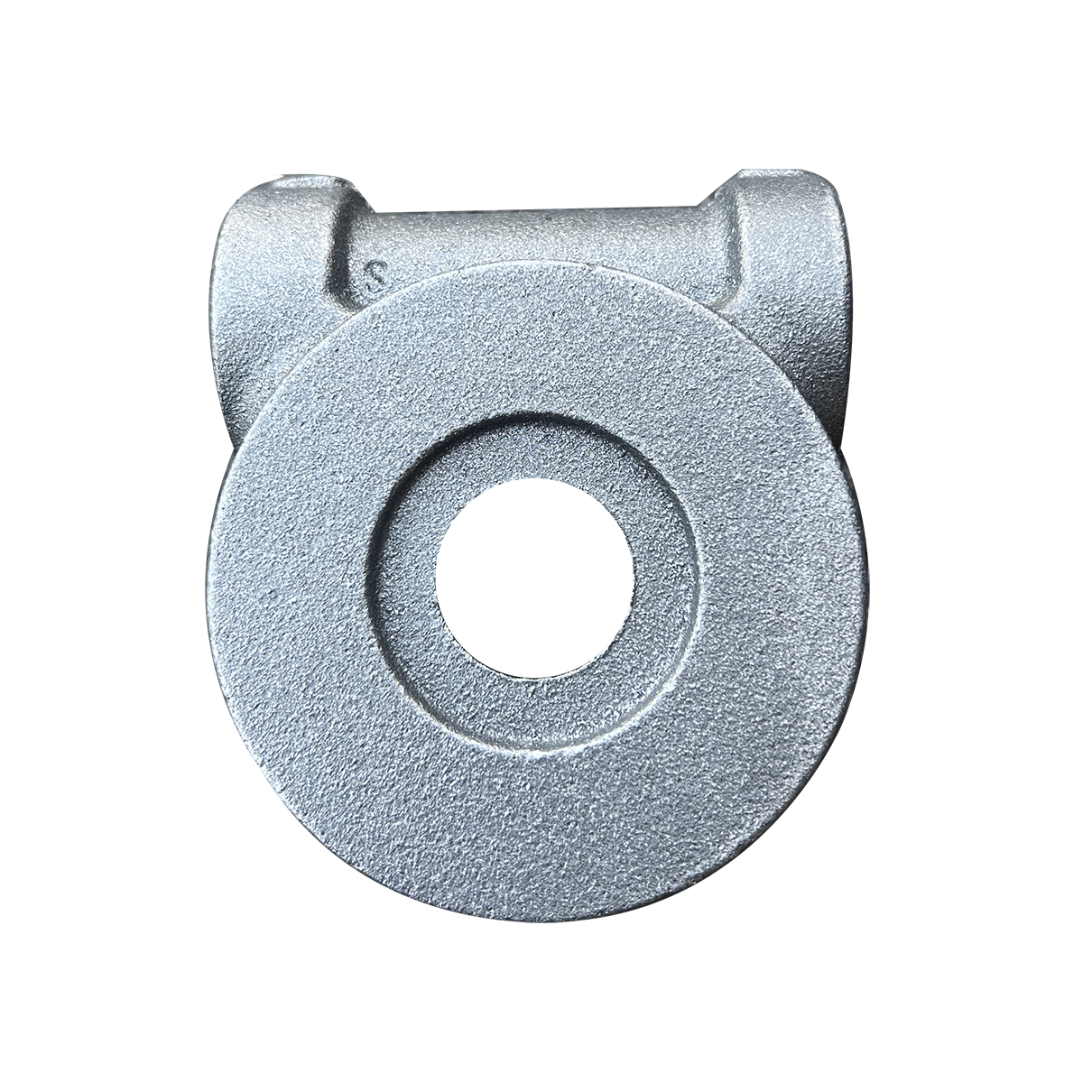

Aluminum Cast Mold and Pattern A Comprehensive Overview

Aluminum casting is a widely utilized manufacturing process that transforms molten aluminum into various shapes and products. Central to this process are aluminum cast molds and patterns, which play a crucial role in determining the quality and precision of the final output. Understanding how molds and patterns work is essential for anyone involved in the casting industry.

1. The Role of Molds in Aluminum Casting

Molds are the cavities into which molten aluminum is poured to form specific shapes. They can be made from various materials, including sand, metal, or ceramic, depending on the casting method and desired properties of the final product. There are two primary types of molds permanent molds and expendable molds.

Permanent molds are made from metals and can be reused multiple times, leading to enhanced production efficiency and better dimensional accuracy. Expendable molds, often made from sand, are used for single-use purposes, allowing for intricate designs but requiring more extensive cleanup after each casting. Both types of molds must be designed with precision to ensure that the final aluminum piece meets the required specifications.

2. The Importance of Patterns

al cast mold and pattern

Patterns are replicas of the desired end product and are used to create molds. They can be made from various materials, including wood, plastic, or metal. The choice of pattern material typically depends on the complexity of the design and the number of castings needed. Patterns are crucial as they directly influence the mold's shape, surface finish, and overall quality of the cast aluminum object.

During the pattern-making process, allowances must be made for shrinkage, machining, and any potential defects that may arise during casting. This requires a thorough understanding of the properties of aluminum, as it tends to contract as it cools.

3. Innovations in Aluminum Casting

Advancements in technology have significantly impacted the aluminum casting industry. Innovations such as 3D printing technology have revolutionized the pattern-making process, allowing for rapid prototyping and a reduction in lead times. This enables manufacturers to produce complex designs that were previously difficult or impossible to create.

Additionally, modern simulation software helps in optimizing the mold design, identifying potential issues before physical production. This not only improves the quality of aluminum castings but also enhances process efficiency and reduces material waste.

In conclusion, aluminum cast molds and patterns are pivotal elements in the casting process. Understanding their design, functionality, and the advancements in technology not only aids in producing high-quality products but also streamlines the production process, making it an essential topic for professionals in the manufacturing field.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025