Eki . 10, 2024 18:21 Back to list

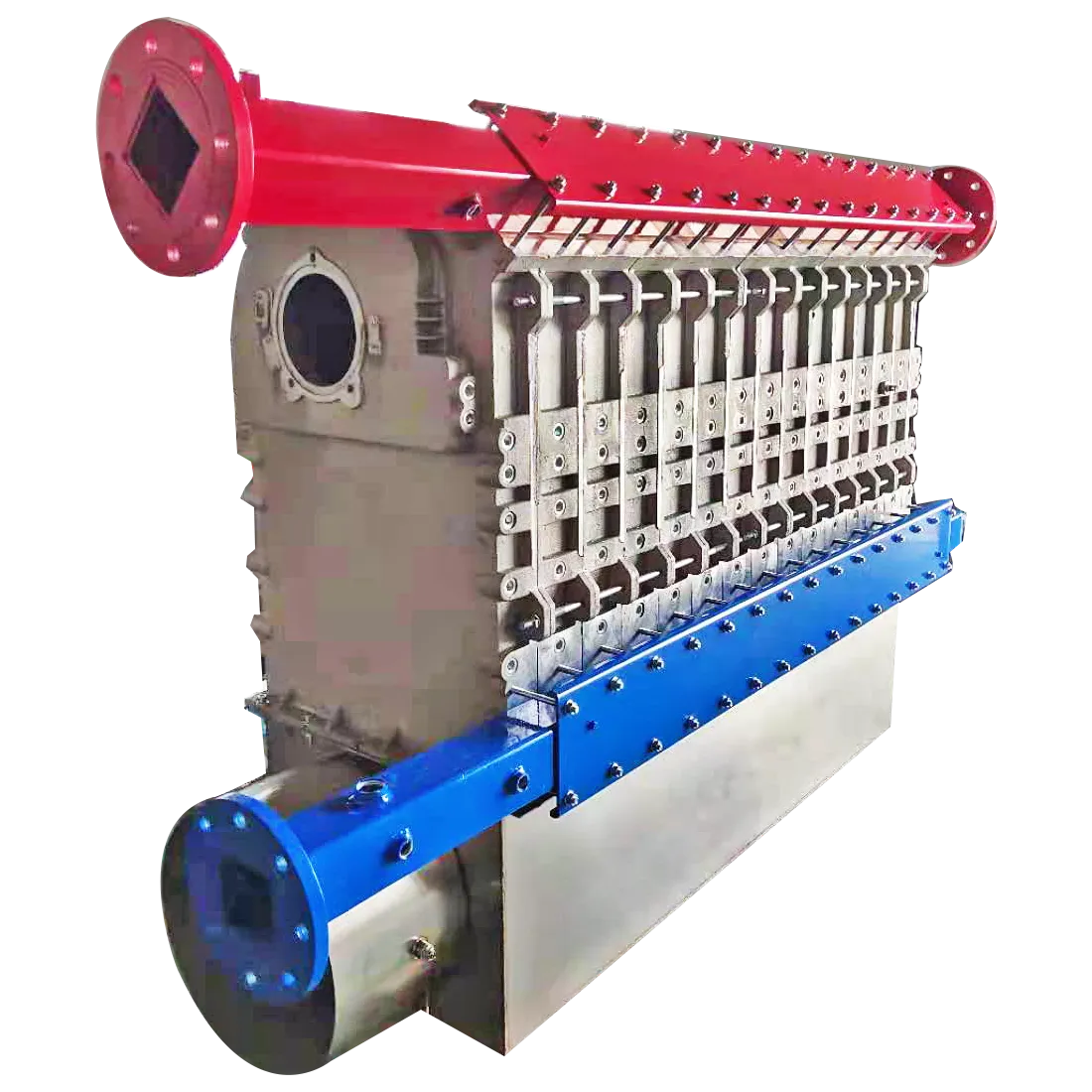

cast iron parts exporter

The Role of Cast Iron Parts Exporters in Global Trade

In today's interconnected world, the significance of cast iron parts exporters cannot be overstated. Cast iron, known for its exceptional durability, versatility, and resistance to wear and deformation, is a material widely used in various industries, including automotive, construction, plumbing, and manufacturing. The exportation of cast iron components not only boosts economies but also meets the growing global demand for high-quality engineering materials.

Understanding Cast Iron

Cast iron is an iron-carbon alloy, characterized by its high carbon content that typically ranges from 2% to 4%. The unique properties of cast iron, such as its excellent castability, fluidity during pouring, and good machinability, make it an ideal choice for a myriad of applications. There are various types of cast iron, including gray iron, ductile iron, and white iron, each possessing distinct characteristics that lend themselves to specific uses.

For instance, gray iron is widely used for engine blocks and machine frames due to its excellent damping capabilities and good machinability. Ductile iron, on the other hand, is known for its high tensile strength and ductility, making it suitable for components like gears and pipes. This diversity in applicability means that cast iron parts exporters play a pivotal role in supplying critical components to industries worldwide.

The Global Market for Cast Iron Parts

The global demand for cast iron parts has surged significantly over the past few decades, driven by industrial growth in emerging economies, particularly in Asia and Africa. Countries like China and India have seen rapid expansion in their manufacturing sectors, leading to an increased requirement for robust materials such as cast iron. Additionally, developed regions like North America and Europe continue to rely on cast iron for various industrial applications, ensuring a steady market for exporters.

The market dynamics have also shifted due to innovation and advancements in production techniques. Modern foundries are now equipped with state-of-the-art technology that enhances casting quality and efficiency, allowing exporters to offer high-quality products. This not only ensures compliance with international quality standards but also strengthens the competitive edge in the global marketplace.

Key Players in the Export Sector

cast iron parts exporter

The cast iron parts export industry comprises various key players, including manufacturers, distributors, and trading companies. Manufacturers often work directly with foundries to produce specific components tailored to client specifications. These companies invest heavily in research and development to innovate and improve product quality, thus meeting the ever-evolving demands of the market.

Furthermore, established exporters leverage their understanding of international logistics to ensure timely delivery of products. They navigate complex trade regulations, tariffs, and customs requirements, allowing clients to focus on their core business operations. This expertise not only simplifies the procurement process for importers but also fosters long-term business relationships built on trust and reliability.

Challenges Facing Cast Iron Parts Exporters

Despite the myriad opportunities, cast iron parts exporters encounter several challenges. One of the most pressing issues is the fluctuating prices of raw materials. The cost of iron ore and other alloying elements can be volatile due to market conditions, affecting production costs and profit margins. Exporters must strategically manage their supply chains and pricing models to remain competitive.

Additionally, compliance with environmental regulations is increasingly vital. Many countries have stringent laws regarding emissions and waste management in metal casting. Exporters must adapt their processes to adhere to these regulations while maintaining product quality. This often requires investment in cleaner technologies and environmentally friendly practices, which can strain financial resources but ultimately contribute to sustainability.

The Future of Cast Iron Parts Export

Looking ahead, the future of cast iron parts export appears promising. As industries continue to evolve and demand for durable materials rises, cast iron remains a reliable choice. Innovations in production techniques, coupled with the growing focus on sustainability, are set to enhance the efficiency and eco-friendliness of cast iron manufacturing.

Moreover, the ongoing effort to expand into new markets, particularly in developing regions, presents a significant opportunity for exporters. By emphasizing quality, reliability, and customer service, cast iron parts exporters can secure their position in the global supply chain.

In conclusion, cast iron parts exporters play a crucial role in the global economy, providing essential components to various industries. By navigating challenges and leveraging opportunities, these exporters contribute significantly to international trade and industrial advancement. As the world increasingly seeks reliable materials, the importance of cast iron is likely to remain strong in the foreseeable future.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025