Oca . 12, 2025 09:32 Back to list

FULLY-PREMIXED LOW-NITROGEN CONDENSING BOILER FOR COMMERCIAL PURPOSE

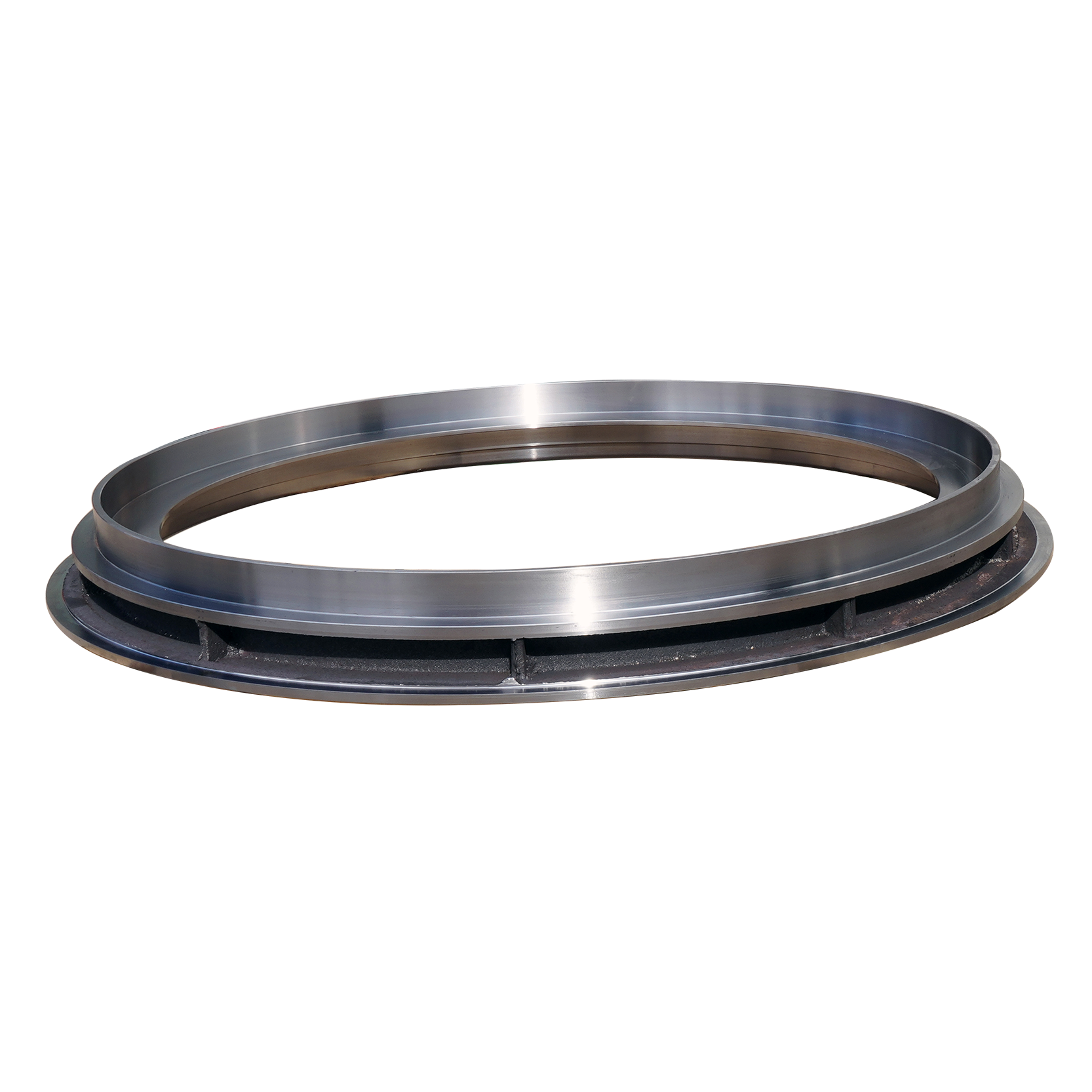

Reinforced concrete pipes, known for their durability and strength, are a cornerstone of modern infrastructure projects. Their manufacturing relies heavily on high-quality molds, or moulds as referred to in British English, with pallet systems playing a crucial role. These components are essential not just for the shaping and formation of the pipes, but for ensuring overall product quality that meets various construction standards.

Moreover, environmental factors are increasingly influencing the design and material choices for these molds. Sustainable practices are being adopted, with recyclable steel and energy-efficient manufacturing processes becoming standard practice. This aligns with overarching industry trends aimed at reducing carbon footprints and promoting environmentally friendly construction practices. Trustworthiness in the production process comes from stringent quality checks and balances. Reputable manufacturers implement rigorous testing procedures to ensure that each mold and pallet function effectively under anticipated stress conditions. These tests often simulate real-world usage scenarios to identify potential failure points, ensuring that the reinforced concrete pipes produced meet safety and regulatory standards. The expertise required to design and manufacture these components is considerable, requiring an in-depth understanding of material science, structural engineering, and manufacturing processes. This specialized knowledge ensures that manufacturers can deliver products that not only meet but exceed client expectations, optimizing both performance and reliability. In summary, reinforced concrete/cement pipe molds and pallets are integral to the construction of durable infrastructure. Their development is marked by a blend of traditional craftsmanship and modern technological innovation, driving improvements in efficiency, reliability, and sustainability. As infrastructure demands evolve, the continued advancement in mold and pallet technology will play a pivotal role in meeting these challenges head-on, delivering the next generation of safe and resilient concrete piping systems.

Moreover, environmental factors are increasingly influencing the design and material choices for these molds. Sustainable practices are being adopted, with recyclable steel and energy-efficient manufacturing processes becoming standard practice. This aligns with overarching industry trends aimed at reducing carbon footprints and promoting environmentally friendly construction practices. Trustworthiness in the production process comes from stringent quality checks and balances. Reputable manufacturers implement rigorous testing procedures to ensure that each mold and pallet function effectively under anticipated stress conditions. These tests often simulate real-world usage scenarios to identify potential failure points, ensuring that the reinforced concrete pipes produced meet safety and regulatory standards. The expertise required to design and manufacture these components is considerable, requiring an in-depth understanding of material science, structural engineering, and manufacturing processes. This specialized knowledge ensures that manufacturers can deliver products that not only meet but exceed client expectations, optimizing both performance and reliability. In summary, reinforced concrete/cement pipe molds and pallets are integral to the construction of durable infrastructure. Their development is marked by a blend of traditional craftsmanship and modern technological innovation, driving improvements in efficiency, reliability, and sustainability. As infrastructure demands evolve, the continued advancement in mold and pallet technology will play a pivotal role in meeting these challenges head-on, delivering the next generation of safe and resilient concrete piping systems.

Share

Latest news

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025