Şub . 12, 2025 11:04 Back to list

tube in tube cooler

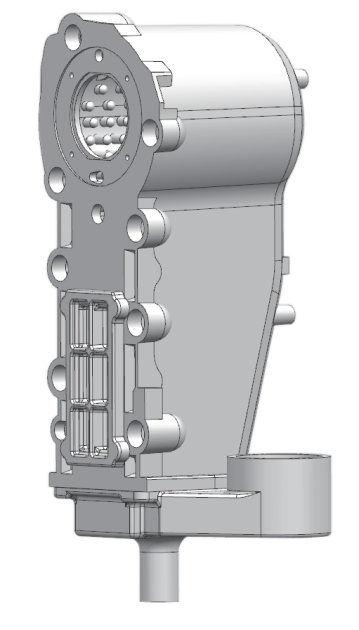

In the realm of industrial cooling, one revolutionary advancement stands out the tube-in-tube cooler. This innovative product has reshaped how heat exchange processes are executed, offering efficiency that is not only paramount but unparalleled. For businesses that heavily rely on effective thermal management solutions, understanding the nuances of the tube-in-tube cooler can translate into enhanced operational productivity and energy savings, ultimately influencing the bottom line.

Authoritativeness in the domain of industrial cooling systems is often derived from peer endorsements and empirical results. Experts within the industry consistently recommend the tube-in-tube cooler due to its adaptability and resilience. The cooler’s capability to handle varying pressure and temperature profiles without succumbing to stress corrosion or mechanical fatigue marks it as a preferred choice in sectors where precision and reliability cannot be compromised. Substantial case studies have demonstrated its supremacy in applications that range from petrochemical processes, where high thermal loads are a constant, to pharmaceutical manufacturing, where maintaining product integrity through controlled temperatures is critical. Trustworthiness in the deployment of tube-in-tube coolers is bolstered by rigorous quality assurance protocols that these coolers undergo. Leading manufacturers adhere to stringent industry standards, regularly subjecting their products to endurance testing that simulates real-world operational conditions. Clients who choose tube-in-tube coolers benefit from warranties and service agreements that further cement trust, ensuring that any potential issues are addressed promptly and efficiently. This reliability fosters a partnership, rather than a mere vendor relationship, with manufacturers who are invested in the success and satisfaction of their industrial clients. As industries continue to evolve and the demand for efficient energy use grows ever more critical, tube-in-tube coolers offer a compelling solution. Their innovative design, proven reliability, and the backing of expert endorsements make them an invaluable asset in industrial thermal management. In an era where precision and efficiency are not merely advantageous but essential, investing in a tube-in-tube cooler becomes not just a choice, but a strategic imperative for future-ready businesses.

Authoritativeness in the domain of industrial cooling systems is often derived from peer endorsements and empirical results. Experts within the industry consistently recommend the tube-in-tube cooler due to its adaptability and resilience. The cooler’s capability to handle varying pressure and temperature profiles without succumbing to stress corrosion or mechanical fatigue marks it as a preferred choice in sectors where precision and reliability cannot be compromised. Substantial case studies have demonstrated its supremacy in applications that range from petrochemical processes, where high thermal loads are a constant, to pharmaceutical manufacturing, where maintaining product integrity through controlled temperatures is critical. Trustworthiness in the deployment of tube-in-tube coolers is bolstered by rigorous quality assurance protocols that these coolers undergo. Leading manufacturers adhere to stringent industry standards, regularly subjecting their products to endurance testing that simulates real-world operational conditions. Clients who choose tube-in-tube coolers benefit from warranties and service agreements that further cement trust, ensuring that any potential issues are addressed promptly and efficiently. This reliability fosters a partnership, rather than a mere vendor relationship, with manufacturers who are invested in the success and satisfaction of their industrial clients. As industries continue to evolve and the demand for efficient energy use grows ever more critical, tube-in-tube coolers offer a compelling solution. Their innovative design, proven reliability, and the backing of expert endorsements make them an invaluable asset in industrial thermal management. In an era where precision and efficiency are not merely advantageous but essential, investing in a tube-in-tube cooler becomes not just a choice, but a strategic imperative for future-ready businesses.

Share

Pervious:

Next:

Latest news

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025