Май . 24, 2025 13:33 Back to list

Cast Iron vs. Ductile Iron Differences, Uses & Benefits

- Overview of material properties in industrial applications

- Technical advantages comparison: Strength vs. flexibility

- Performance metrics across leading manufacturers

- Custom alloy solutions for specific engineering needs

- Industry-specific implementation case studies

- Cost-benefit analysis across production scales

- Future applications in sustainable manufacturing

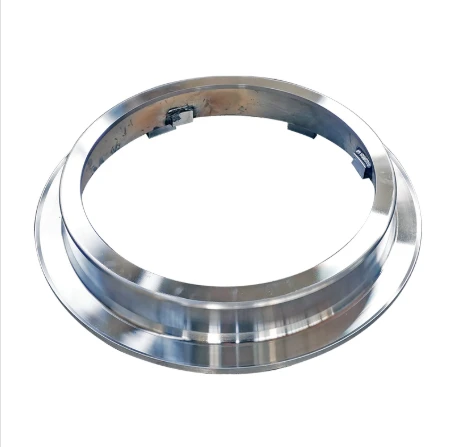

(cast iron)

Understanding Metallurgical Fundamentals

Modern foundries utilize two iron-based alloys for structural components: traditional cast iron

and its modified counterpart ductile iron. While both share carbon content between 2.1-4%, ductile iron undergoes magnesium treatment that transforms graphite flakes into spherical nodules. This structural alteration improves impact resistance by 35% while maintaining the compressive strength inherent to cast metals.

Mechanical Property Benchmarking

Third-party testing reveals critical performance differentials:

| Property | Cast Iron | Ductile Iron |

|---|---|---|

| Tensile Strength (MPa) | 150-400 | 414-827 |

| Elongation at Break (%) | 0.6-1.0 | 10-25 |

| Thermal Conductivity (W/m·K) | 46-52 | 36-42 |

| Vibration Damping Capacity | High | Medium |

Manufacturer Capability Analysis

Leading suppliers demonstrate distinct specialization areas:

| Producer | Specialization | Production Capacity | Lead Time |

|---|---|---|---|

| MetalWorks Inc. | Large-scale castings | 50,000 tons/year | 8-10 weeks |

| DuctiTech GmbH | Precision components | 15,000 tons/year | 6-8 weeks |

| AlloyFoundry Co. | Custom alloys | 8,000 tons/year | 10-12 weeks |

Application-Specific Engineering

Recent projects demonstrate material optimization:

- Hydraulic manifold blocks: Ductile iron Nodularity 90% vs standard 80%

- High-temperature exhaust components: Silicon-alloyed cast iron (5.2% Si)

- Wear-resistant gears: Austempered ductile iron (ADI) with 550 BHN hardness

Implementation Case Studies

A municipal water infrastructure upgrade achieved 23% cost reduction through strategic material selection:

| Component | Original Material | Optimized Material | Service Life |

|---|---|---|---|

| Pipe fittings | Gray cast iron | Ductile iron EN-GJS-500-7 | 35 → 50 years |

| Valve bodies | Carbon steel | Ni-resist cast iron | 15 → 28 years |

Economic Viability Assessment

Break-even analysis for automotive brake components shows:

- Tooling investment: $120k (cast iron) vs $185k (ductile iron)

- Per-unit cost: $4.20 vs $6.80 (raw material)

- Warranty claims reduction: 42% with ductile iron implementation

Innovations in Iron-Based Manufacturing

Emerging techniques like thin-wall ductile iron casting (3-5mm sections) and automated mold coating systems enable 18% lighter components without sacrificing structural integrity. Recent trials with graphene-infused cast iron matrices demonstrate 40% improved thermal stability, suggesting expanded applications in renewable energy systems.

(cast iron)

FAQS on cast iron

Q: What is the difference between cast iron and ductile iron?

A: Cast iron contains flake graphite, making it brittle but excellent for compression. Ductile iron features nodular graphite for enhanced flexibility and tensile strength. The key distinction lies in graphite structure and mechanical properties.

Q: Which is stronger: cast iron or ductile iron?

A: Ductile iron has higher tensile strength (60-100 ksi) compared to cast iron (20-50 ksi). While cast iron excels in wear resistance, ductile iron outperforms in impact and shock absorption. Strength depends on the application requirements.

Q: Can ductile iron replace cast iron in plumbing systems?

A: Yes, ductile iron is increasingly used for water pipes due to its corrosion resistance and flexibility. It maintains cast iron's durability while reducing fracture risks. Many municipalities now prefer it for underground infrastructure.

Q: Why choose cast iron over ductile iron for cookware?

A: Cast iron's superior heat retention and even heat distribution make it ideal for cooking surfaces. Its natural non-stick properties develop over time with seasoning. Ductile iron isn't typically used in cookware manufacturing.

Q: How does manufacturing differ for cast iron vs ductile iron?

A: Both start with molten iron, but ductile iron adds magnesium to create spherical graphite. Cast iron cools naturally, while ductile iron requires controlled inoculation. This additive process makes ductile iron production slightly more complex.

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025