Дек . 10, 2024 05:06 Back to list

frc concrete pipe mold/mould bottom ring

Understanding FRC Concrete Pipe Molds and Mould Bottom Rings

The construction industry has seen significant advancements over the years, particularly in the efficiency and reliability of various materials and manufacturing techniques. Among these advancements, Fiber Reinforced Concrete (FRC) has emerged as a robust option for producing concrete pipes, which are vital for various infrastructure projects, including drainage systems, sewer systems, and aqueducts. Central to the production process are FRC concrete pipe molds, specifically their bottom rings, which play a crucial role in shaping and forming these essential conduits.

What is FRC?

Fiber Reinforced Concrete is a composite material that integrates fibrous materials, such as steel, glass, or synthetic fibers, into the traditional concrete mix. The inclusion of fibers enhances the structural integrity, ductility, and overall performance of the concrete. FRC exhibits improved resistance to cracking, improved load-bearing capacity, and enhanced longevity, which makes it suitable for demanding environments typically associated with pipe applications.

The Role of Molds in Concrete Pipe Production

Concrete pipe molds are integral to the manufacturing process of concrete pipes. These molds determine the final shape, size, and surface finish of the pipes produced. Traditionally, molds are made from steel or engineered plastics, ensuring durability and precision in the production line.

The bottom ring of the mold is particularly important because it serves as the foundation for the pipe being formed. It must be designed to withstand the weight of the concrete as well as any internal pressure the finished pipe will face. The bottom ring must also enable smooth release of the concrete once it has set, which is essential for maintaining the mold’s lifespan and ensuring quality control in production.

Features of Mould Bottom Rings

frc concrete pipe mold/mould bottom ring

1. Material Selection They are typically constructed from high-grade steel or reinforced polymer materials. This ensures that they can handle the mechanical stresses faced during concrete curing and the weight of the final product.

2. Design Precision The design of the bottom rings must strictly adhere to specifications that guarantee the dimensions of the resulting pipes. Any deviation in size can lead to significant issues during installation, leading to repair costs and potentially impacting public safety.

3. Ease of Use A well-designed bottom ring allows for easy assembly and disassembly, facilitating efficient production cycles. This aspect is critical for manufacturers aiming to produce large volumes without compromising quality.

4. Durability and Maintenance Mould bottom rings should be resistant to wear and tear, especially given the harsh conditions that can occur during concrete production. Regular maintenance and proper care can prolong the life of these molds, providing a better return on investment for manufacturers.

Advances in Production Techniques

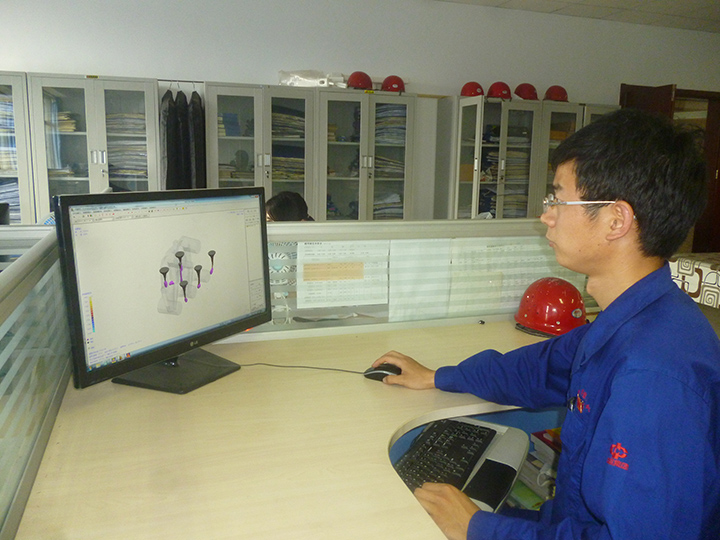

Modern manufacturers are continually refining their techniques and mold designs to produce higher quality concrete pipes at a lower cost. Automation and computer-aided design (CAD) are playing pivotal roles in this evolution. Advanced mold designs allow for faster production rates while ensuring consistency across batches. Additionally, integrating technologies such as 3D printing for prototype molds is enabling manufacturers to experiment with innovative designs quickly.

Conclusion

FRC concrete pipe molds, particularly the mould bottom rings, are essential components in the production of durable and reliable concrete pipes. With the growing importance of FRC in the construction industry, it becomes increasingly crucial to invest in quality mold design and manufacturing processes. As the demand for effective infrastructure continues to rise, focusing on the advances in mold technology and materials will remain critical for manufacturers aiming to meet the challenges of modern construction needs efficiently and effectively.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025