Жов . 30, 2024 13:22 Back to list

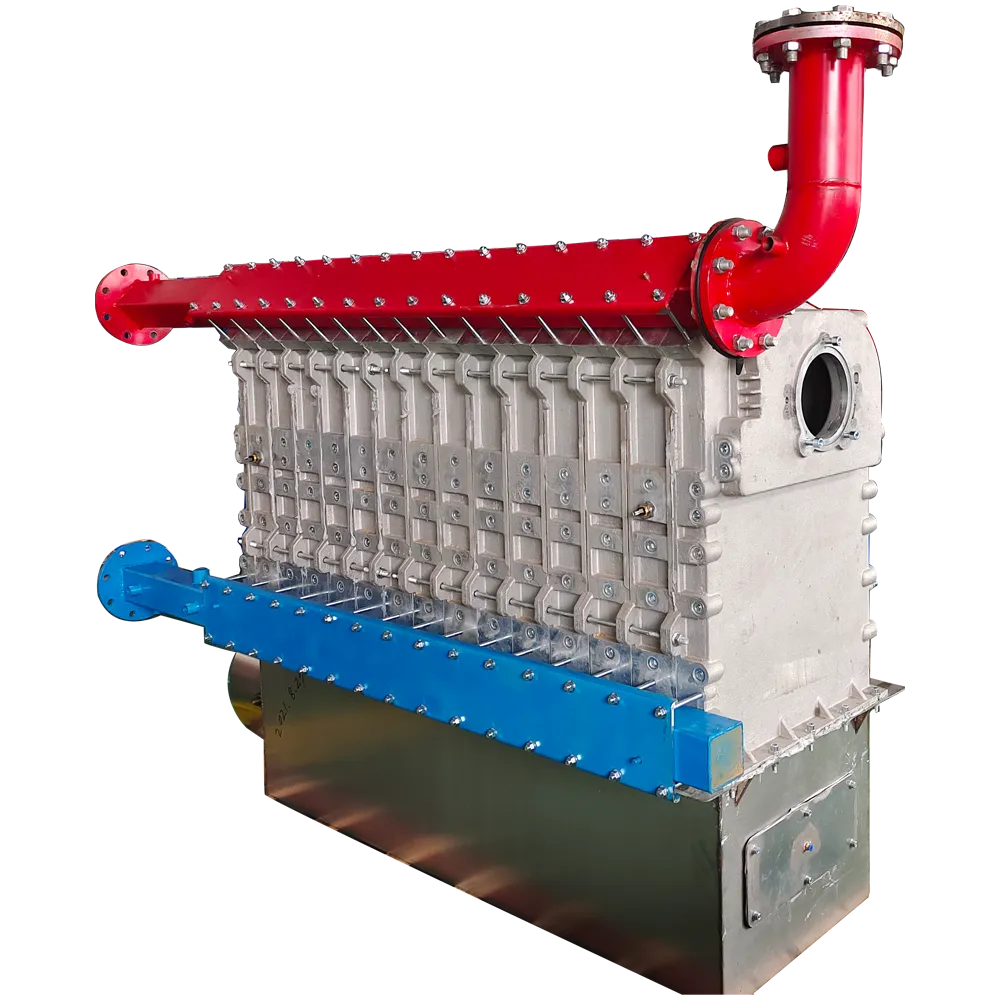

oem milling body casting

Understanding OEM Milling Body Casting A Comprehensive Overview

The manufacturing industry continuously seeks innovative solutions to enhance production efficiency, quality, and cost-effectiveness. One area that has garnered significant attention is OEM milling body casting. Original Equipment Manufacturer (OEM) milling body casting plays a crucial role in various sectors, from automotive to aerospace, where precision and durability are paramount.

OEM milling body casting involves the creation of complex geometries that form the core components of milling machines. These components, often referred to as milling bodies, are essential for the operational efficiency of the machines, directly influencing their performance and longevity. The casting process allows manufacturers to produce intricate shapes and designs that would be impossible to achieve through traditional machining methods alone.

Understanding OEM Milling Body Casting A Comprehensive Overview

There are several casting techniques utilized in producing OEM milling bodies, including sand casting, investment casting, and die casting. Sand casting is popular due to its versatility and cost-effectiveness, making it ideal for both small and large production runs. Investment casting, known for its ability to produce highly detailed parts with excellent surface finishes, is often preferred for high-precision applications. On the other hand, die casting is favored for its speed and efficiency in mass production, making it a go-to choice for companies looking to minimize lead times.

oem milling body casting

A key advantage of OEM milling body casting is the ability to use a variety of materials, including aluminum, steel, and various alloys. This adaptability allows manufacturers to select materials that best meet the performance requirements of the milling bodies. For instance, aluminum castings offer lightweight yet strong solutions, ideal for aerospace applications, while steel castings provide the durability required in heavy industrial machinery.

Quality control is paramount in the OEM milling body casting process. Stringent inspections are conducted to ensure that the final products meet specific standards and tolerances. Advanced testing methods, such as non-destructive testing and metallurgical analysis, are employed to identify any potential defects before the components are put into service.

Moreover, sustainability is becoming an increasingly important factor in the casting industry. Many manufacturers are now focusing on eco-friendly practices, incorporating recycled materials and energy-efficient processes into their operations. This commitment not only helps in reducing the environmental footprint but also aligns with the growing demand for sustainable manufacturing solutions.

In conclusion, OEM milling body casting is an integral part of modern manufacturing, providing essential components that support various industries. By leveraging advanced materials and innovative casting techniques, manufacturers can produce high-quality, durable milling bodies that enhance machine performance and efficiency. As technology continues to advance, the future of OEM milling body casting looks promising, with new possibilities for innovation and sustainability on the horizon.

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025