جنوری . 20, 2025 00:01 Back to list

stainless steel casting foundry

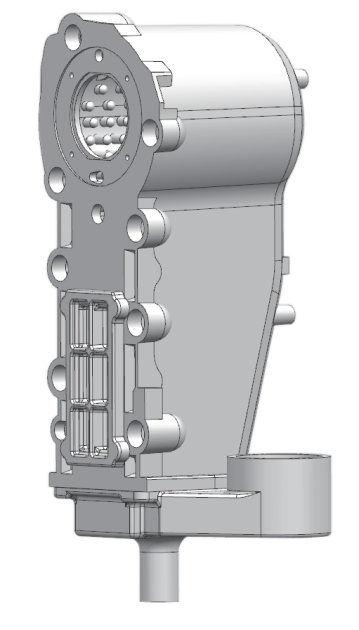

The art and science of stainless steel casting foundries are steeped in a rich history of precision, innovation, and technology. As globalization surges and industries demand high-performance materials, stainless steel casting foundries have emerged as pivotal players, supplying top-tier components that meet stringent quality standards.

Moreover, sustainability has become a cornerstone in the operations of leading foundries. By optimizing energy consumption and minimizing waste through recycling and reuse strategies, foundries not only reduce their environmental footprint but also enhance operational efficiency. This commitment to sustainable practices not only aligns with global environmental standards but also resonates with eco-conscious clients. The application scope of stainless steel castings is extensive, further emphasizing their critical role in modern manufacturing. In the medical industry, stainless steel is indispensable for surgical instruments and implants owing to its biocompatibility and resistance to sterilization processes. In the aerospace sector, its ability to withstand extreme temperatures and stress makes it ideal for engine components. The automotive industry relies on stainless steel casting to deliver components that require high strength-to-weight ratios, contributing to vehicle performance and safety. Trustworthiness, a key pillar of a successful foundry, extends beyond process and product integrity. It encompasses transparent client communications, robust partnerships, and an unwavering commitment to ethical business practices. Foundries earn trust not only through superior product delivery but also through their responsiveness and adaptability to client needs and market dynamics. In conclusion, stainless steel casting foundries are indispensable to the fabric of modern industry. Their role goes beyond mere production; they are centers of innovation, excellence, and sustainability. A foundry's authority is not just measured by its output but by its continual pursuit of improvement, its adherence to quality, and its alignment with global standards. As we continue to push the boundaries of what is possible with stainless steel casting, foundries will undoubtedly remain at the forefront, forging the future with metal and precision.

Moreover, sustainability has become a cornerstone in the operations of leading foundries. By optimizing energy consumption and minimizing waste through recycling and reuse strategies, foundries not only reduce their environmental footprint but also enhance operational efficiency. This commitment to sustainable practices not only aligns with global environmental standards but also resonates with eco-conscious clients. The application scope of stainless steel castings is extensive, further emphasizing their critical role in modern manufacturing. In the medical industry, stainless steel is indispensable for surgical instruments and implants owing to its biocompatibility and resistance to sterilization processes. In the aerospace sector, its ability to withstand extreme temperatures and stress makes it ideal for engine components. The automotive industry relies on stainless steel casting to deliver components that require high strength-to-weight ratios, contributing to vehicle performance and safety. Trustworthiness, a key pillar of a successful foundry, extends beyond process and product integrity. It encompasses transparent client communications, robust partnerships, and an unwavering commitment to ethical business practices. Foundries earn trust not only through superior product delivery but also through their responsiveness and adaptability to client needs and market dynamics. In conclusion, stainless steel casting foundries are indispensable to the fabric of modern industry. Their role goes beyond mere production; they are centers of innovation, excellence, and sustainability. A foundry's authority is not just measured by its output but by its continual pursuit of improvement, its adherence to quality, and its alignment with global standards. As we continue to push the boundaries of what is possible with stainless steel casting, foundries will undoubtedly remain at the forefront, forging the future with metal and precision.

Share

Pervious:

Next:

Latest news

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025