Noy . 27, 2024 13:52 Back to list

FRP Concrete Pipe Mold Bottom Ring Production and Manufacturing Solutions

The Importance of High-Quality Concrete Pipe Mold Bottom Rings in FRC Manufacturing

In the realm of construction and infrastructure development, the demand for durable and high-quality materials is paramount. One critical component in the production of concrete pipes is the bottom ring of the mold, especially in the context of Fiber Reinforced Concrete (FRC). This article delves into the significance of FRC concrete pipe mold bottom rings, the manufacturing processes involved, and the benefits of partnering with reputable manufacturers.

Understanding FRC and Its Advantages

Fiber Reinforced Concrete (FRC) is a composite material that incorporates fibers into the concrete mix, enhancing its ductility and resistance to cracking. The introduction of fibers improves the mechanical properties of concrete, making it an excellent choice for various structural applications, including drainage systems, wastewater treatment facilities, and stormwater management.

The production of FRC pipes requires precise and reliable molds, and this is where the bottom ring comes into play. The bottom ring forms the base of the concrete pipe mold and is integral to achieving the desired shape and stability during the curing process. A well-designed bottom ring ensures that the outer dimensions of the pipe meet specifications, providing structural integrity and durability.

The Role of the Bottom Ring in the Molding Process

The bottom ring is typically constructed from high-quality steel or durable plastic materials that can withstand the high pressures and weights of concrete. Its primary function is to maintain the shape of the pipe while it sets, preventing any deformation that could compromise the pipe's structural integrity.

When producing FRC pipes, the bottom ring must be designed to allow for easy release after the curing process to minimize wastage and improve production efficiency. A well-engineered bottom ring provides a smooth release, ensuring that the finished product can be extracted without damage or additional finishing work.

Choosing the Right Manufacturer

Selecting a qualified manufacturer for concrete pipe mold bottom rings is crucial for ensuring the quality of FRC pipes. Reputable manufacturers will have extensive experience in producing molds specifically designed for FRC applications, ensuring that their designs account for unique factors such as the type of fibers used and the specific requirements of the concrete mix.

When evaluating manufacturers, consider the following criteria

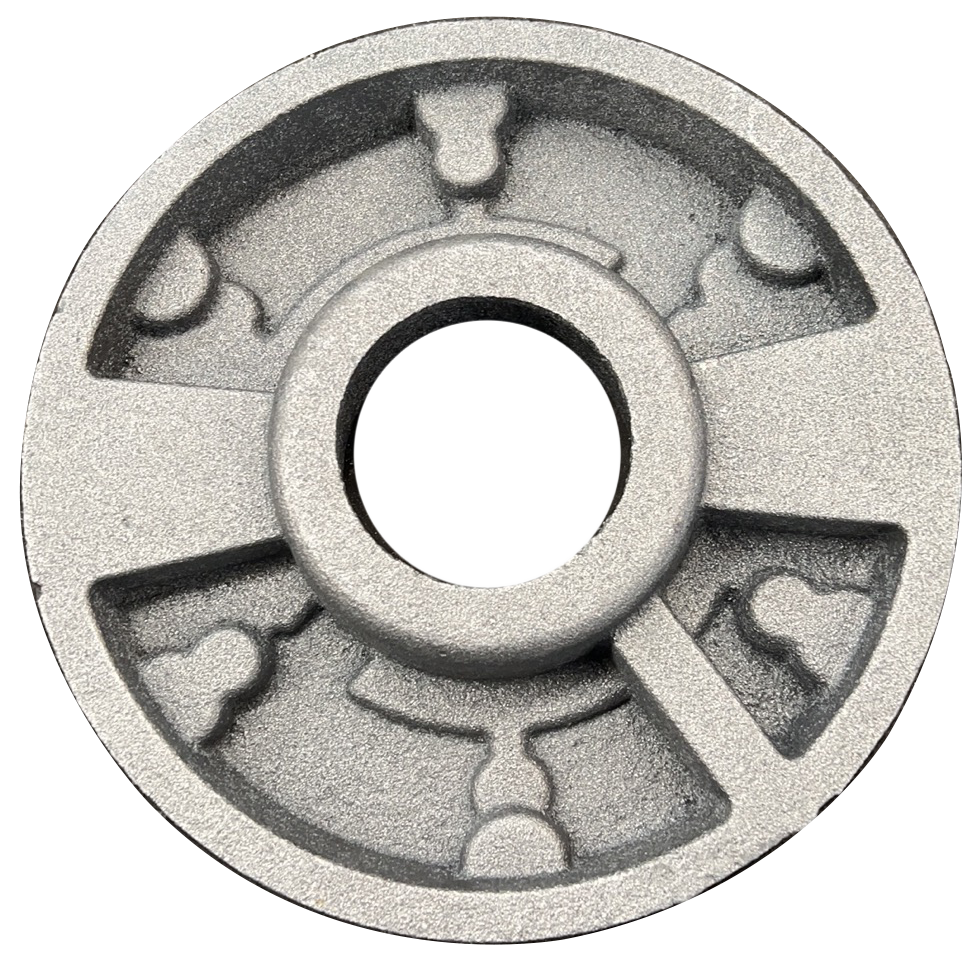

frc concrete pipe mold bottom ring manufacturer

1. Quality of Materials The manufacturer should use high-grade materials that provide durability and resistance to wear and tear.

2. Precision Engineering The ability to create molds with precise measurements is essential for maintaining quality standards in production.

3. Customization Options A good manufacturer should offer customization services to cater to specific project needs, including size variations, shapes, and designs.

4. Reputation and Experience Look for manufacturers with a proven track record in the industry and positive customer feedback.

5. Technical Support Effective communication and technical assistance throughout the production process can help address any challenges that may arise.

Benefits of High-Quality Bottom Rings

Investing in high-quality concrete pipe mold bottom rings brings numerous advantages. First, it leads to increased efficiency in the production process, as a durable and well-engineered bottom ring minimizes downtime and maintenance.

Secondly, high-quality molds improve the final product's quality, resulting in pipes that are less prone to cracking or failure. This, in turn, enhances the overall reliability of the infrastructure built using these pipes, contributing to safer and longer-lasting systems.

Lastly, partnering with a reputable manufacturer often means access to ongoing support and innovative solutions as technology advances. This can result in further improvements in both the manufacturing process and the quality of the finished concrete products.

Conclusion

In conclusion, the bottom ring of concrete pipe molds is a critical component in the effective production of Fiber Reinforced Concrete pipes. Engaging with a trusted manufacturer is essential for ensuring high-quality molds that contribute to the overall success of construction projects. By prioritizing quality, precision, and innovation, contractors can enhance the reliability and longevity of their infrastructure investments.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025