Th11 . 24, 2024 22:20 Back to list

Understanding Gray Cast Iron Class 30 Properties and Applications in Engineering

Understanding Gray Cast Iron Class 30 Properties and Applications

Gray cast iron, also known as gray iron, is one of the most widely used materials in various engineering applications. Among the different classifications of gray cast iron, Class 30 is significant due to its unique properties and wide range of uses. This article delves into the characteristics, benefits, and applications of Gray Cast Iron Class 30, providing a comprehensive overview for engineers, designers, and manufacturers.

Composition and Microstructure

Gray cast iron is primarily composed of iron, carbon, and silicon. The carbon content usually ranges between 2.5% and 4%, while silicon constitutes about 1% to 3%. The formation of graphite flakes within the iron matrix gives gray cast iron its distinguished gray appearance. In Class 30, the material has a minimum tensile strength of 30,000 psi (approximately 207 MPa) and a typical hardness around 180-220 Brinell Hardness (HB).

The microstructure of Gray Cast Iron Class 30 is characterized by its graphite flakes, which are crucial in determining its mechanical properties. The distribution and size of these flakes influence the material’s strength, ductility, and machinability. Unlike other types of cast iron, the presence of graphite provides an excellent means of damping vibrations, making it ideal for applications requiring good sound absorption.

Mechanical Properties

The mechanical properties of Gray Cast Iron Class 30 make it a versatile material in engineering applications. Its tensile strength, coupled with good compressive strength and wear resistance, allows Class 30 to perform effectively under stress. Moreover, its lower thermal expansion coefficient compared to other materials minimizes distortion when subjected to thermal changes.

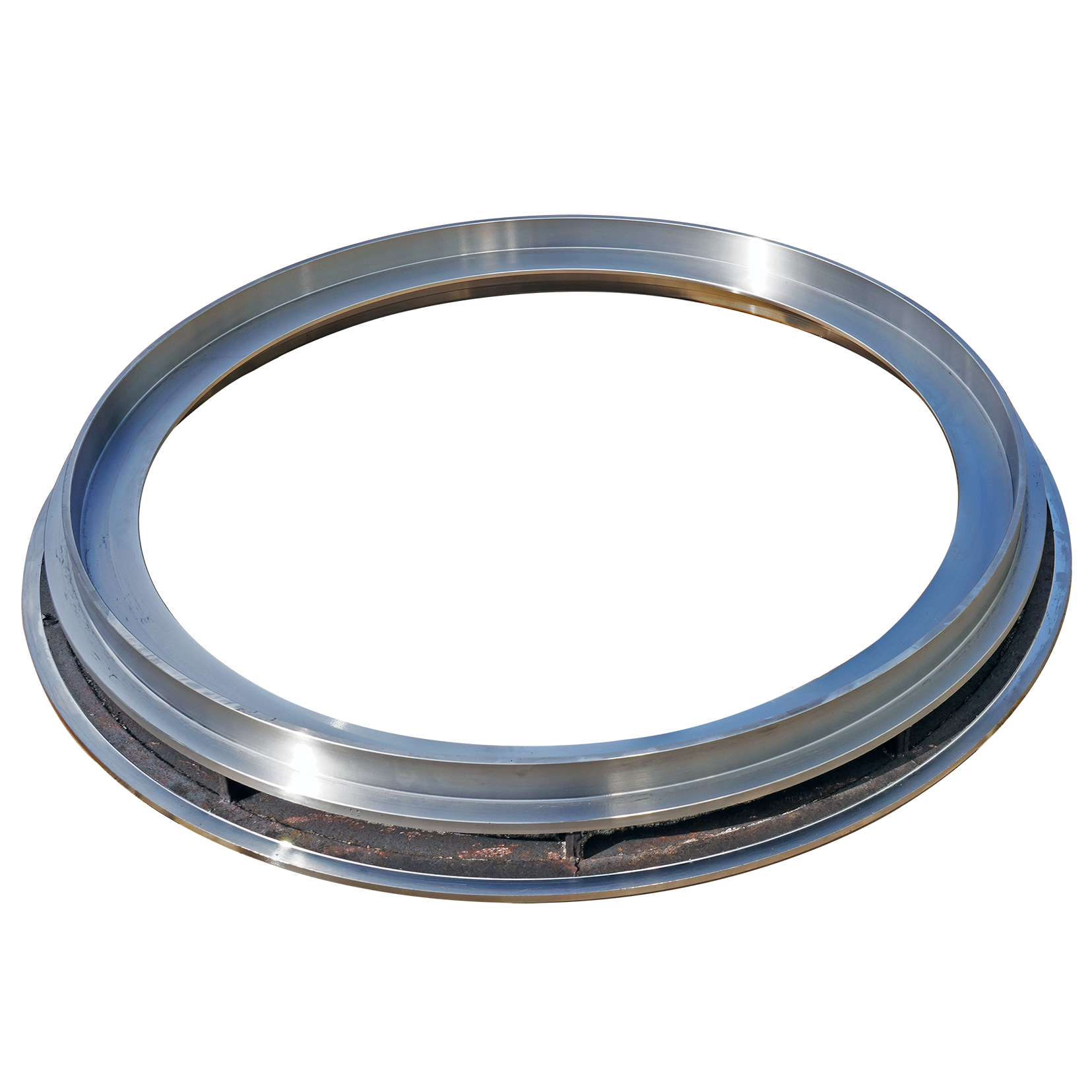

gray cast iron class 30

One of the remarkable features of Gray Cast Iron Class 30 is its machinability. Being easy to machine, it is often used in complex shapes and components that require precision. This attribute, combined with its ability to retain tight tolerances, makes it a preferred choice in manufacturing applications where dimensional accuracy is paramount.

Applications

The diverse properties of Gray Cast Iron Class 30 lend themselves to a variety of applications across different industries. It is commonly utilized in the manufacturing of engine blocks, cylinder heads, machine tool bases, and housing components. The automotive industry heavily relies on Class 30 gray iron for its high-performance components due to its excellent wear resistance and ability to withstand high pressure.

Additionally, Class 30 is often chosen for making heavy machinery parts, such as gears and bearings, where the need for durability and strength is critical. The material’s vibration-damping capabilities make it particularly suitable for applications in power generation, where machinery noise must be minimized.

In construction and infrastructure, Gray Cast Iron Class 30 finds usage in plumbing systems, drainage covers, and architectural castings. Its excellent corrosion resistance, particularly when treated with specific coatings, extends its utility in outdoor environments and harsh conditions.

Conclusion

Gray Cast Iron Class 30 is a material that balances strength, durability, and machinability, making it a popular choice in various industries. Its unique microstructure allows for excellent performance in a wide range of applications, from automotive to construction and machinery. Understanding the properties of Class 30 gray iron enables engineers and designers to make informed choices in material selection, ensuring the reliability and efficiency of their products. As industries evolve and new applications emerge, the role of Gray Cast Iron Class 30 will continue to be relevant, adapting to meet the demands of modern engineering challenges.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025