Th12 . 31, 2024 13:45 Back to list

home built heat exchanger

Building Your Own Heat Exchanger A Practical Guide

Creating your own heat exchanger at home can be a rewarding project, particularly for those interested in energy efficiency or DIY home improvement. A heat exchanger is a system designed to transfer heat between two or more fluids, which can be useful in a variety of applications such as heating water, space heating, or improving the efficiency of HVAC systems. This article will guide you through the basics of home-built heat exchangers, discussing types, materials, and construction tips.

Understanding Heat Exchangers

At its core, a heat exchanger works by allowing two fluids at different temperatures to pass by each other, facilitating heat transfer. The simplest form is the counterflow heat exchanger, where one fluid flows in the opposite direction to the other. This method maximizes the efficiency of heat transfer, making it a popular choice for DIY projects.

Types of Heat Exchangers

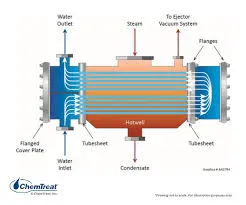

1. Shell and Tube This type consists of a series of tubes, one set carrying the hot fluid and the other the cold fluid. It is widely used in industrial applications but can be adapted for home use.

2. Plate Heat Exchanger These comprise multiple thin plates stacked together, creating channels for the fluids to flow. They are compact and efficient, making them suitable for limited spaces.

3. Air-to-Air Heat Exchanger This kind is often used in ventilation systems to transfer heat between inbound and outbound airflows, enhancing energy efficiency in heating and cooling systems.

4. Water-to-Water Heat Exchanger Utilized in applications such as radiant floor heating or swimming pool heating, this type transfers heat from one body of water to another.

Materials for Construction

home built heat exchanger

When building your heat exchanger, the choice of materials is crucial for effective heat transfer and durability. Common materials include

- Copper Excellent thermal conductivity, but can be more expensive. - Aluminum Lightweight and effective for small heat exchangers. - Stainless Steel Offers good corrosion resistance and is often used for water applications. Ensure the materials you choose are compatible with the fluids being used in your system to prevent any adverse reactions.

Design and Construction Tips

1. Determine the Size Begin by calculating the size of the heat exchanger required for your specific application. This will depend on the flow rates and temperature differences of the fluids involved.

2. Create a Design Sketch out your heat exchanger's design. If building a shell and tube design, ensure you have enough tubes to facilitate efficient heat transfer. For a plate heat exchanger, stack the plates securely to avoid leaks.

3. Assembly Carefully assemble the chosen materials, ensuring your connections are leak-proof. Use appropriate seals and fittings to maintain pressure and prevent fluid loss.

4. Testing Once assembled, run tests to ensure that the heat exchanger operates efficiently. Monitor the temperature change and flow rates to evaluate its performance.

5. Insulation For improved efficiency, insulate the sections of the heat exchanger where heat loss may occur, particularly in areas exposed to lower temperatures.

Conclusion

Building your own heat exchanger can be a practical solution to enhance energy efficiency in your home. While the construction process requires careful planning and execution, the rewards in terms of reduced energy costs and improved comfort can be significant. Whether you choose a simple water-to-water exchanger for heating tasks or a more complex plate exchanger for a specialized application, the knowledge and skills gained will be invaluable for future DIY projects. With the right materials, design, and a bit of ingenuity, you can create a functional and effective heat exchanger tailored to your needs. Happy building!

-

OEM Cast Silicon Aluminum Alloy Heat Exchanger | Custom & High Performance

NewsAug.25,2025

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025