Jan . 20, 2025 02:16 Back to list

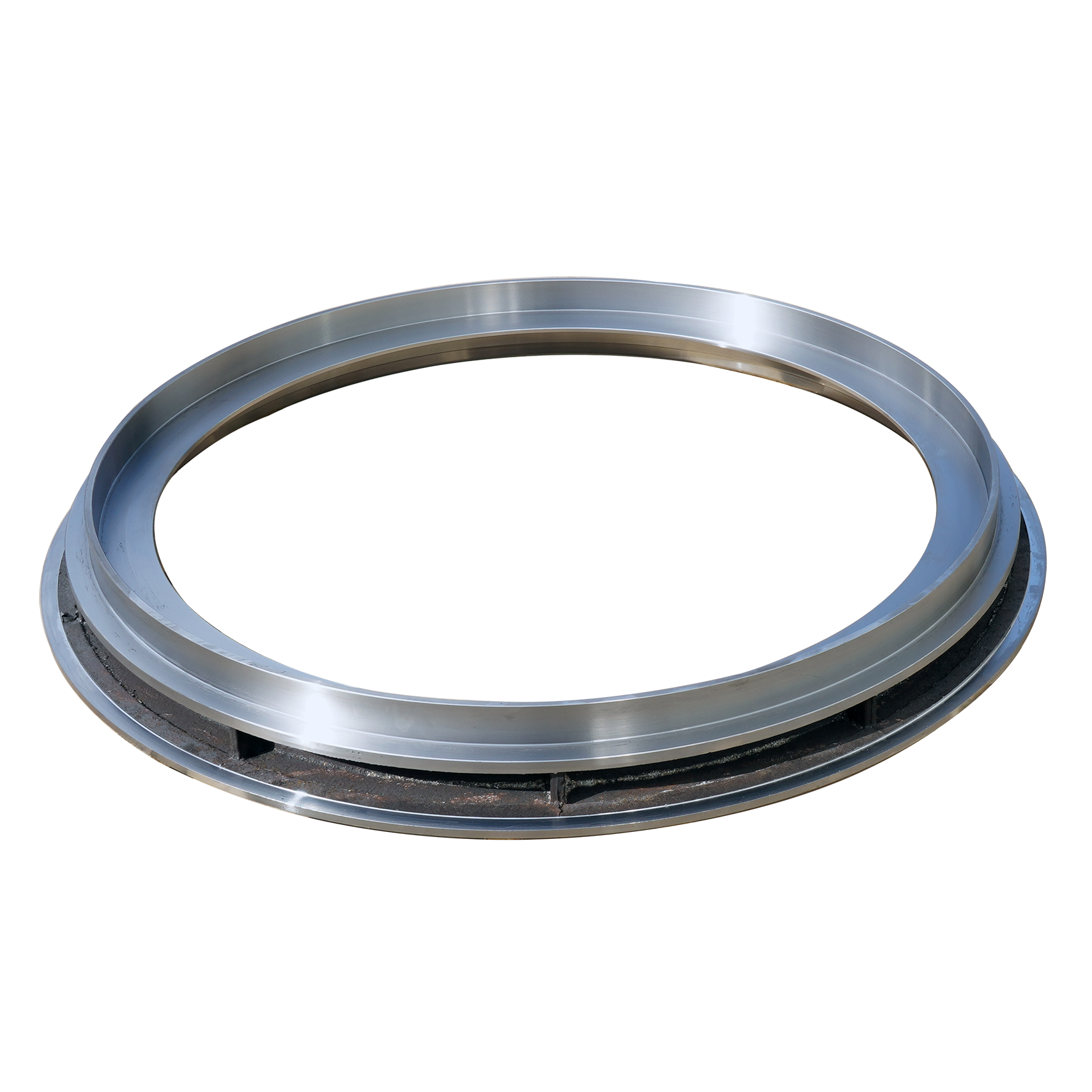

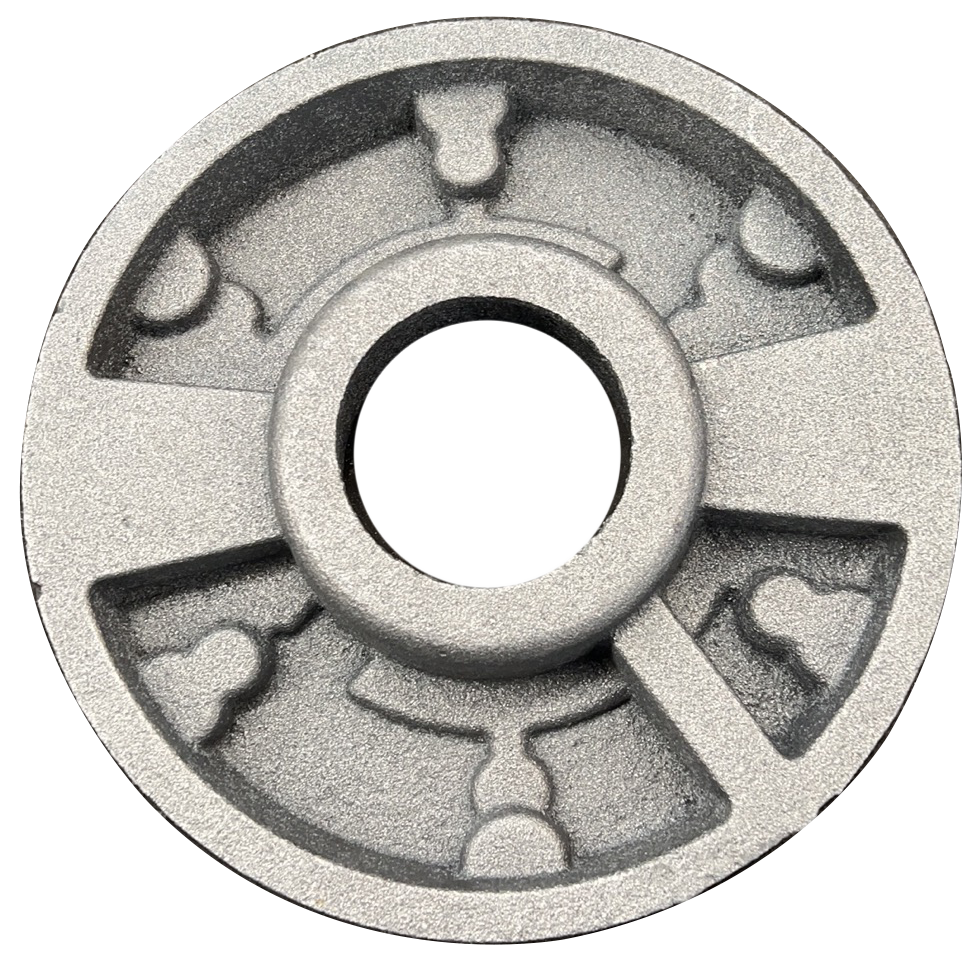

cast ductile iron pipe

Ductile casting, an essential process in modern manufacturing, possesses unique properties that lend robustness and flexibility to a wide array of products across industries. Its significance lies in its ability to produce materials that combine high strength with ductility, allowing for parts that can withstand substantial stress without fracturing. As an expert with extensive experience in this domain, let's delve into the expertise, authoritativeness, and trustworthiness that ductile casting brings to the table, especially for product development and innovation.

Trustworthiness is a hallmark of ductile casting, primarily due to its predictable and reproducible nature. The casting process, honed over decades, ensures a consistent quality that end users can rely on for high-performance applications. Certified foundries adhere to established industry standards such as ISO 9001 and IATF 16949, ensuring that every batch of cast components meets precise engineering criteria. Moreover, the reliability of ductile castings in critical infrastructure applications—such as pipelines and pressure vessels—demonstrates their essential role in maintaining public safety and maintaining trust among stakeholders. In the broader context of product development, ductile casting provides an invaluable toolset for engineers and designers. Its combination of strength, ductility, and fatigue resistance opens new possibilities for innovation, enabling the development of novel products that must perform under demanding conditions. Companies that harness the potential of ductile casting not only benefit from the material's intrinsic properties but also gain a competitive edge in delivering solutions that stand out in terms of quality and longevity. In conclusion, ductile casting stands as a testament to the synthesis of experience, expertise, authoritativeness, and trustworthiness in the metallurgical arena. Its role in advancing modern manufacturing is underscored by its ability to produce parts that uphold the highest standards of performance. For industries seeking to push the envelope in engineering excellence, ductile casting remains a cornerstone process that continues to unlock new frontiers in product innovation.

Trustworthiness is a hallmark of ductile casting, primarily due to its predictable and reproducible nature. The casting process, honed over decades, ensures a consistent quality that end users can rely on for high-performance applications. Certified foundries adhere to established industry standards such as ISO 9001 and IATF 16949, ensuring that every batch of cast components meets precise engineering criteria. Moreover, the reliability of ductile castings in critical infrastructure applications—such as pipelines and pressure vessels—demonstrates their essential role in maintaining public safety and maintaining trust among stakeholders. In the broader context of product development, ductile casting provides an invaluable toolset for engineers and designers. Its combination of strength, ductility, and fatigue resistance opens new possibilities for innovation, enabling the development of novel products that must perform under demanding conditions. Companies that harness the potential of ductile casting not only benefit from the material's intrinsic properties but also gain a competitive edge in delivering solutions that stand out in terms of quality and longevity. In conclusion, ductile casting stands as a testament to the synthesis of experience, expertise, authoritativeness, and trustworthiness in the metallurgical arena. Its role in advancing modern manufacturing is underscored by its ability to produce parts that uphold the highest standards of performance. For industries seeking to push the envelope in engineering excellence, ductile casting remains a cornerstone process that continues to unlock new frontiers in product innovation.

Share

Pervious:

Next:

Latest news

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025