- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

10 月 . 17, 2024 02:27 Back to list

bronze investment casting supplier

Bronze Investment Casting Suppliers A Key Component in Manufacturing

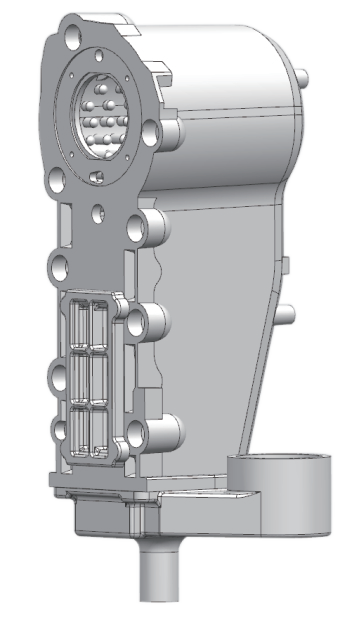

In the world of manufacturing, precision and quality are paramount. Among various methods of metal casting, investment casting stands out for its ability to produce intricate shapes with high dimensional accuracy. When it comes to bronze investment casting, suppliers play a crucial role in ensuring that these complex components meet the stringent requirements of various industries.

Bronze, an alloy primarily made of copper and tin, is favored for its excellent corrosion resistance, strength, and aesthetic appeal. These properties make bronze a suitable choice for a myriad of applications, including automotive, marine, aerospace, and artistic elements. However, producing high-quality bronze castings requires not just advanced technology but also skilled craftsmanship and reliable supply chains.

Investment casting, also known as lost-wax casting, involves several meticulous steps. A wax pattern is created, coated in ceramic material, and then heated to remove the wax, leaving behind a precise mold. Molten bronze is then poured into this mold, creating complex shapes that are often impossible to achieve with traditional casting methods. The process allows for a high degree of customization, enabling manufacturers to meet specific customer requirements.

bronze investment casting supplier

When selecting a bronze investment casting supplier, several factors need consideration. First, the supplier’s experience and reputation in the industry can provide insight into their capability to deliver high-quality products. It’s essential to look for a supplier that utilizes state-of-the-art technology and adheres to the best practices in quality control.

Additionally, a good supplier should offer a range of services, including design assistance, prototyping, and post-casting processes like machining and finishing. This comprehensive approach can significantly streamline the manufacturing process, reducing lead times and costs for clients.

Moreover, the supplier's ability to handle varying order quantities—from small runs to large volumes—can make a significant difference for businesses with fluctuating demands. Environmental and sustainability practices are also becoming increasingly important, so selecting suppliers who prioritize eco-friendly processes can enhance a company’s corporate social responsibility profile.

In conclusion, the importance of choosing the right bronze investment casting supplier cannot be overstated. Their expertise and capabilities are essential in delivering high-quality, intricate components that meet the demanding needs of modern manufacturing. As industries continue to evolve, the role of these suppliers will be pivotal in driving innovation and maintaining high standards in production.

-

Custom Cast Silicon Aluminum Heat Exchangers for Hot Water Boilers

NewsJun.02,2025

-

Stainless Steel Impellers - Custom & Durable Solutions ODM Available

NewsJun.02,2025

-

Stamping Concrete Pipe Mold Bottom Ring Custom & Durable Solutions

NewsJun.02,2025

-

Custom Furniture Hardware Durable & Affordable Solutions Shop Now

NewsJun.01,2025

-

SRC Concrete Pipe Bottom Ring Durable & Customizable Solutions

NewsJun.01,2025

-

Machine Base Casting Solutions Custom & ODM Precision Castings

NewsMay.31,2025