10 月 . 20, 2024 16:50 Back to list

custom die casting

Understanding Custom Die Casting A Comprehensive Overview

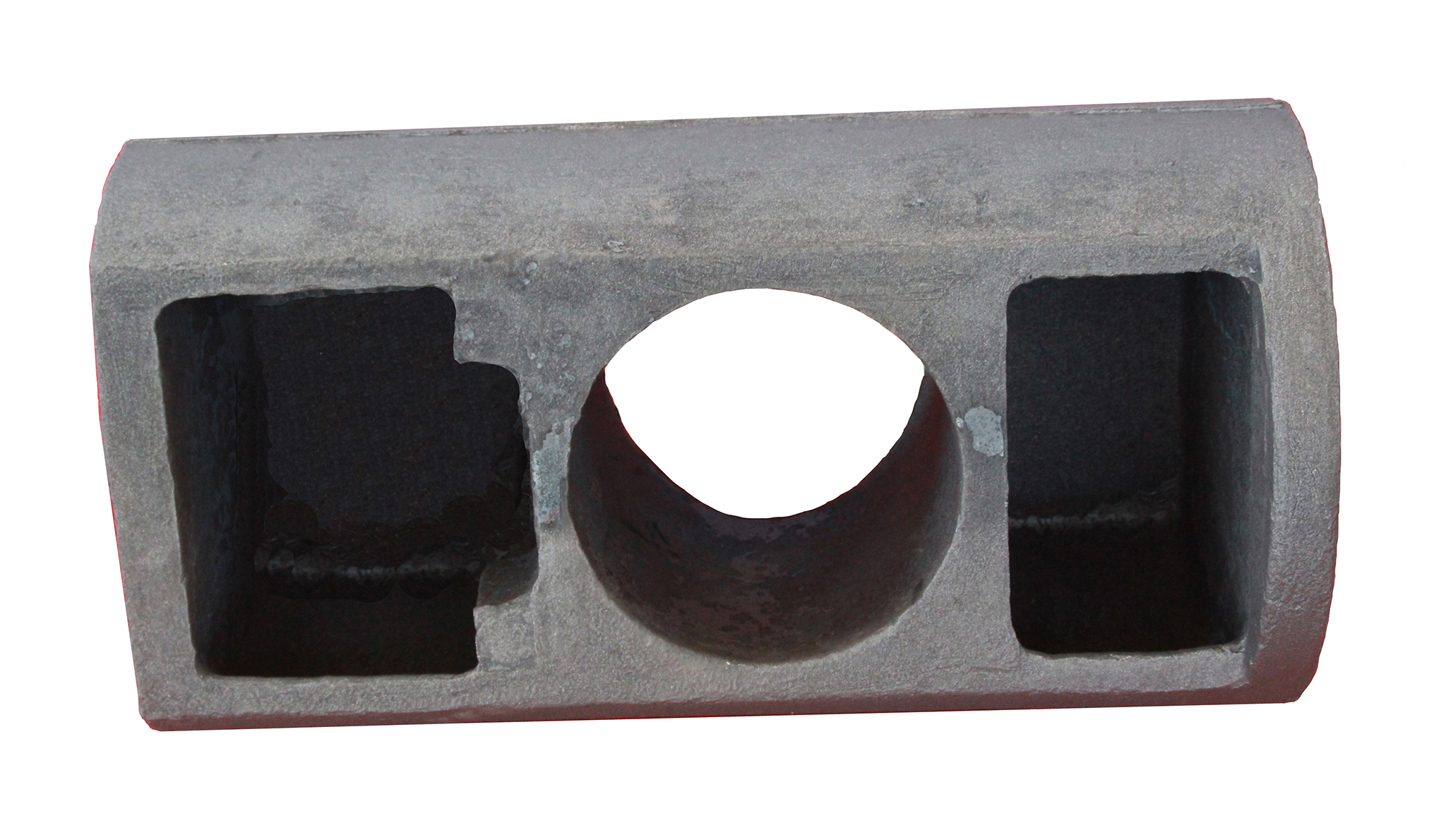

Custom die casting is a manufacturing process that is widely used in the production of complex metal parts in various industries. This technique involves the use of molten metal that is injected into a mold cavity under high pressure, allowing for the precise creation of intricate shapes and designs. One of the primary advantages of custom die casting is its ability to produce high-quality, consistent parts with excellent surface finishes and dimensional accuracy.

The Process of Custom Die Casting

The custom die casting process begins with the design of the mold. Engineers work closely with clients to develop a mold that meets their specific requirements, considering factors like material type, tolerances, and production volume. The mold itself consists of two halves, which are constructed from durable materials such as steel or aluminum to withstand the high pressures and temperatures involved in the casting process.

Once the mold design is finalized, the production phase commences. Molten metal—commonly aluminum, zinc, or magnesium—is heated to its melting point and then injected into the mold at high speed. This rapid injection process ensures that the metal fills every nook and cranny of the mold, capturing intricate details and features. After the molten metal cools and solidifies, the mold is opened, and the finished part is ejected. The entire process can take just a few seconds, allowing for high production rates.

Advantages of Custom Die Casting

Custom die casting offers several key advantages that make it a preferred choice for manufacturers

1. Precision and Accuracy One of the standout benefits of die casting is its ability to produce parts with tight tolerances and complex geometries. This level of precision reduces the need for post-processing, saving time and costs.

2. Material Efficiency Die casting typically results in less waste compared to traditional machining methods. The process is highly efficient, as the majority of the material used is transformed into usable parts.

custom die casting

3. Superior Surface Finish Parts produced through custom die casting have an excellent surface finish, often requiring minimal surface treatment before assembly. This feature is particularly valuable in industries where aesthetics and functionality are paramount.

4. Variety of Materials Custom die casting can accommodate a range of metal alloys, allowing manufacturers to select the most suitable material for their specific application. Each material possesses unique properties that can improve performance, such as corrosion resistance or lightweight characteristics.

5. High Production Rates The rapid cycle time of die casting enables high-volume production, making it ideal for manufacturers needing large quantities of components. This efficiency translates into lower cost per unit, even for complex designs.

Applications Across Industries

The versatility of custom die casting makes it applicable in various industries. In the automotive sector, parts such as engine components, transmission housings, and structural parts are commonly manufactured using this process. The electronics industry also benefits from die casting for producing housings and component parts due to the lightweight and durable nature of die-cast metals.

Furthermore, the aerospace industry relies on custom die casting for creating lightweight yet robust components that can withstand extreme pressures and temperatures. Other sectors, including consumer goods and industrial equipment, also utilize die casting for its efficiency and quality.

Conclusion

In summary, custom die casting is a highly effective manufacturing technique that provides numerous advantages, including precision, material efficiency, and excellent surface finishes. Its adaptability allows it to meet the demands of various industries, making it an essential process in modern manufacturing. As technology continues to evolve, the future of custom die casting promises even greater innovations, further solidifying its role in producing high-quality components for a wide range of applications. Whether for automotive, aerospace, or consumer products, custom die casting remains a cornerstone of manufacturing excellence.

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025

-

Buy Cast Iron Pipe: Premium Ductile Iron & Drain Solutions

NewsAug.07,2025

-

Durable Cast Iron Water Main Pipe | Buy Ductile Pipe

NewsAug.06,2025