- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

12 月 . 13, 2024 01:05 Back to list

punching concrete pipe mould pallet factories

The Role of Punching in Concrete Pipe Manufacturing Insights from Mould and Pallet Factories

Concrete pipes are a critical component in various infrastructure projects, including drainage systems, sewage treatment facilities, and water supply networks. The production of these pipes often involves the use of specialized moulds and pallets, and one significant process in this manufacturing is punching. This article delves into the importance of punching in the production of concrete pipe moulds and pallets, examining its impact on quality, efficiency, and overall product integrity.

Understanding the Basics

Punching is a manufacturing process that involves creating holes or indentations in materials using a punch and die mechanism. In the context of concrete pipe production, punching is typically utilized to create openings for reinforcement, drainage, or other functional requirements. The precision and quality of the punching process can significantly influence the performance characteristics of the final product.

Importance of Moulds and Pallets

In concrete pipe manufacturing, moulds are the essential structures that shape the concrete mixture into pipes. Pallets serve as the base on which these moulds are placed during the curing process. Both moulds and pallets are integral to achieving the desired shapes and dimensions of the pipes. Therefore, the quality of their design and manufacturing is crucial for the efficiency and reliability of the concrete pipe production process.

The Punching Process in Mould and Pallet Factories

In mould and pallet factories, the punching process is employed to meet specific design requirements and improve operational efficiency. For example, moulds often require precise holes to accommodate steel reinforcements or to allow for ventilation during the curing of the concrete. Similarly, pallets may need punched holes or slots to facilitate easy handling, stacking, and drying.

Quality Control and Precision

punching concrete pipe mould pallet factories

The punching process must be executed with a high degree of accuracy to ensure that the moulds and pallets meet quality standards. Any misalignment or inconsistency in the punching can lead to defects in the concrete pipes, including structural weaknesses or improper fittings. Therefore, modern mould and pallet factories invest in advanced punching technology and machinery that offer enhanced precision and automation. This investment not only reduces the risk of errors but also increases production speed, permitting higher volume outputs.

Innovations in Punching Techniques

Recent advancements in punching technology have introduced new methods that enhance efficiency and product quality. For instance, computer numerical control (CNC) punching machines provide a level of precision that manual methods simply cannot match. These machines can easily be programmed to create complex patterns or configurations in a fraction of the time it would take with traditional techniques.

Moreover, laser punching systems have emerged as a viable alternative, offering even greater precision and flexibility. These systems can quickly adapt to different designs without the need for extensive re-tooling, which is especially beneficial in a manufacturing environment that requires rapid batch changes.

Environmental Considerations

Sustainability is increasingly becoming a priority in manufacturing processes, including concrete pipe production. The punching process can contribute to environmentally friendly practices by minimizing waste. Precision punching reduces excess material use, and when coupled with best practices in material sourcing and recycling, manufacturers can significantly lessen their environmental footprint.

Conclusion

The punching process plays an indispensable role in the manufacturing of concrete pipe moulds and pallets. By ensuring precise measurements and high-quality outputs, it directly impacts the reliability and performance of concrete pipes used in infrastructure projects. As technology continues to evolve, the integration of advanced punching techniques will undoubtedly enhance productivity and sustainability within the concrete industry. Investing in these innovations is essential for manufacturers looking to maintain competitive advantages in a rapidly changing market. Through meticulous attention to the punching process, concrete pipe manufacturers can ensure that they deliver durable, efficient, and environmentally conscious products to meet the demands of modern infrastructure.

-

High-Precision Colloidal Silica Casting Solutions Custom & ODM

NewsMay.20,2025

-

High-Efficiency Cast Silico Aluminum Gas Boiler ODM & Custom Solutions

NewsMay.20,2025

-

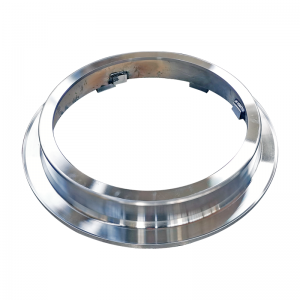

Steel Reinforced Concrete Pipe Bottom Ring Moulds Buy Custom Solutions

NewsMay.19,2025

-

Original Concrete Pipe Mold Bottom Ring & Pallet Chinese Factory Direct Sale

NewsMay.19,2025

-

Custom Room Heating Heat Exchangers Energy-Efficient Solutions

NewsMay.18,2025

-

Precision Milling Body Casting Solutions Custom & ODM Options

NewsMay.18,2025